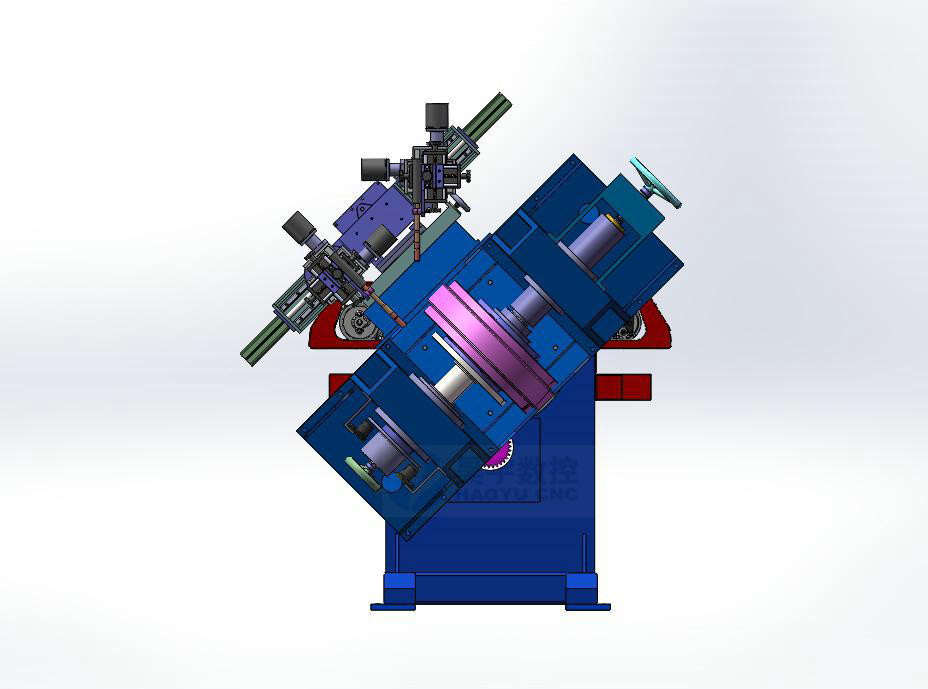

Automatic Welding Machine for Tank

Welding torch will weld double circular seams

Melting thickness and width will be able to reach welding requirement. With uniform and smooth welding appearance.

MIG welding type.The process of MIG welding is a welding process in which an electric arc forms between a consumable wire electrode and the workpiece metal, which heats the workpiece metal, causing them to melt and join. Along with the wire electrode, a shielding gas feeds through the welding gun, which shields the process from contaminants in the air. The process will be automatic.

Machine can work continuously for 24-hour.

1. Left side of machine body is rotary unite, right side is pneumatic thimble. Tank will be fixed by the rotary. Rotation speed is controlled by AC servo motor. And the rotation speed is varied with tank welding position.

2. Japan Omron PLC and touch screen.

3. Workpiece is supported by pneumatic bracket which ensures that it is flexible and convenient to load and unload tank in the process of welding. Thus increases productive capacity and reduces workers' labor intensity.

4. Japan OTC CPVE-400 (rated output current is 400A). Its arc is stable, which controls heat input for good penetration and reduced spatter and smoke. 2 sets power source will go with your machine.

5. Machine base is made of cast iron and thick steel tube.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Automatic Compressor Tank Production Line | Automatic Compressor Tank Production Line Application There are 4 stations: longitudinal seam welding machine, end cap assembling spot welding mach... | |

| longitudinal Argon TIG automatic welding machine | Welding Machine Application: Double welding torch: TIG and MIG. Designed for tank or pipe longitudinal seam. Welding machine control system ca... | |

| automatic cylinder and shaft welding machine | Welding Requirement welding single-end ofplateflange or cylinder bottom forwelding circular seam of hydraulic cylinder. Welding specification i... | |

| Excavator Idler Rebuilding Automatic Welding Machine | Idler Automatic Welding Machine Application welding machine can repair excavator idler Automatic submerged arcweldingmachine. Japan OMRON PLC... | |

| Column & Boom Manipulator Welding Machine with Rotating Roller | 1. Structure: 1-base, 2-welding power source, 3-column, 4-boom, 5-column counter, 6-lifting motor, 7-welding oscillator, 8-welding torch and holde... |

Похожие товары

| XD-MAX Winch for Drone | Продавец: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | Продавец: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | Продавец: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Продавец: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Продавец: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |