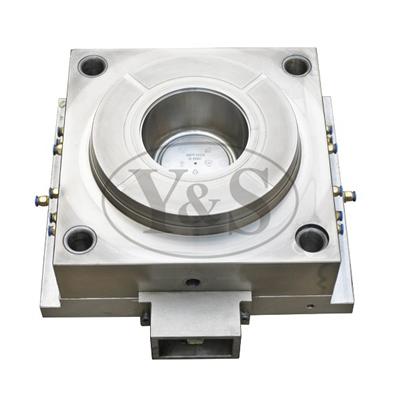

Cutlery Mould

Mould name:cutlery mould Shaping Mode:Injection MouldDisposable cutlery mold, Packaged cutlery mould, Packaged cutlery mold, Disposable cutlery mould, cutlery moldThin wall mold because of its thin wall, light products, high yield, short turnaround time reasons, so the mold production requires a very high clamping structure to be reasonable, the concentricity of the product is higher, not eccentric is not misplaced, waterway design should be reasonable, so as to reduce the molding cycle can yield up to 5 seconds per mold, a mold cavity 4, draft angle to be reasonable, to prevent deformation and die sticking out the top.step1, the sealing surface of the design with zero zero.2, the cartridge body and lid mating surfaces of the air gap 0.15-0.2mm3, the edge of the lid and box body fit at design time and space around 0.8-1mm, specifically to see the product size. 4. The rib design is generally thinner than the products that thin products mostly transparent material, thick tendons prone to bubbles4, the shape of the product is simple, there is no upside down and touch the perforation, similar cups, 3 degrees above the surface of the product can be designed into a gas side, oblique gas, valve, etc.5, the stripper plate rib height 1mm or less, in order to process this rib-bit, the stripper plate can insert up. 3. The multi-cavity mold design methods: (1) Independent Self-locking: multi-cavity independent self-locking fit all shapes thin wall mold design, each independent chamber, the core bottom clamping surface species into the core complex boards. (2) the overall clamping: wall thickness greater than 0.8mm, the machine is relatively small, difficult place to go, with the overall structure, but must explain in advance6, cavity, core design: (1), the complex cavity plate generally use S136 steel. (2), the bottom of the barrel type structure single-chamber cavity is empty, press board must ensure that there is 45mm more than the height of the steel material. Prevent cavities produce flash. (3), along the mouth cavity using inserts, reducing cavity thin steel material to crack. (4) water gate insert sets, reducing the cooling time runnerMain Technique ParametersCavity/CoreMaterial718H, P20, NAK80, 2316, 2738, 2344Product MaterialABS, PPR, PC, PP, PVC, POM, PMMA, PS, PE, PET, Rubber, Silicone, PA, PBT, PEI, etc.BaseLKM or by requestedStructureDouble color injection mould, Solid Mould, Insert Mould, Mould with Slide, Mould with LifterRunner SystemHot runner, Cold runnerCavitySingle cavity, multi cavities by requested (support similar products in one mould)FinishCorrosion word, Mirror finish, BrushedLongevityAvailable SHOTS will depend on the steel material you chooseMould standardHASCO, DME, MISUMI, or by requested etc.SoftwareCAD, Pro-E, UG, etcDesign Time3-7 days after we receive your samples or your drawingsMain TechniqueMilling, Grinding, EDM, Wire-cutting, Engraving, CNC, etc.Production time1-3 months, depends on mould structurePackingWooden case, or by requestThe flow chart to place a mould orderReceive inquiries from customersWe will send you quotation within 24 hours after inquiries confirmedCustomers need to offer samples or 2D/3D drawings and some details about the mouldConfirm the order (quality , price , material , delivery time , payment terms etc.)According to your requirement to prepare the productionClients confirm the details of the mouldSurface shapingDrill holes , high speed carve machine ,wire cutting , EDM, etc.Arranging the test mould and sending the samples to customersIf customers do not satisfy the samples, please give us advice to repairRepair , Polish , TextureWe will send samples to customers for confirmingDelivery by sea or by air ,etcWHY CHOOSE US YUESEN MOULDBelow are just a few reasons to do business with yuesen:- Sufficient experience in plastic mold design and manufacture- Outstanding teamwork- Constant technical innovation- High-quality, low-cost, trouble-free molds- Attentive after-sales services

Другие товары поставщика

|

|

|

Mould name:Rice Cooker Mould Shaping Mode:Injection MouldRice Cooker Mold, rice cooker molding, rice cooker moldsRice Cooker Mould, top door in mol... |

|

|

|

Mould name:Microwave Mould Shaping Mode:Injection MouldMicrowave Mold,Website:, Microwave Molds, Microwave MoldingMicrowave Mould and Microwave Ove... |

|

|

|

Mould name:Fan Mould Shaping Mode:Injection MouldFan Mold,Website:, fan molds, fan moulds, fan moding, Fan MouldingFan mould sets, the key point is... |

|

|

|

Mould name:cutlery mould Shaping Mode:Injection MouldDisposable cutlery mold, Packaged cutlery mould, Packaged cutlery mold, Disposable cutlery mou... |

|

|

|

Mould name:Printer mold Shaping Mode:Injection MouldPrinter mold, Printer moulds, Printer moldingYue Sen Mold is a professional manufacturer of dif... |

Все товары поставщика

Похожие товары