Ladle Furnace

Usage:Ladle refining furnace belongs to the secondary refining equipment, which typically to be used follows the primary melting furnace. Its main function is to remove sulfur, impurity from molten steel and adjust chemical components, thereby, improve quality of molten steel. LF is mainly used in high-quality carbon steel, stainless steel, manganese steel and other metal smelting.Features: 1. LF is not available for smelting, which just used to provide good reduction reaction environment for molten steel.2. LF refining furnace is a ladle as a smelting vessel, with blowing argon stirring, can achieve a better effect of removing sulfur, impurities, as well as adjusting the composition of the alloy.3. If the primary smelting equipment is induction furnace, then follows LF, which can improve the quality of molten steel, completely finish adjusting the alloy composition. (Such as carbon steel can be adjusted as stainless steel or other types of steel in LF)4. If the primary smelting equipment is EAF, then follows LF, which can replace the arc furnace to finish the refining process of molten steel, at the same time, arc furnace only as a melting furnace. This method can significantly improve the smelting efficiency.Production Capacity: 8t—200tStrengths of HC electric arc furnace1. Low power consumptionHC’s large current system made of pure copper as conductive medium, the whole circuit with less resistance. Electrode arm shaped as copper-clad box type, resistance and heat can be reduced efficiently. Reasonable arrange of all conductive systems to minimize the resistance of every circuit.2. Optimized structure, Low failure rate, limited investmentClamping mechanism of the three electrodes is mounted in three separated small box, which installed on one electrode arm and supported by one column, thereby, compared to the traditional three electrodes and three columns, HC’s electrode system is easier, limited investment, lower fault rate.3. Safety & StabilityFull set of hydraulic driving system equipped with accumulator to ensure stability of facilities in the operation process. Whist, equipments can go on the motion when there any emergency accidents happen.4. High flexibility & Maximum simplicity of operationHMI used in electrical automation control, interface simulates the real form of furnace, which make the operation more convenient. Mixing feedstock, charging feedstock, melting, tapping all the commands can be implemented by computer.5. Coordinated with HC’s patented multi-pouring systems, per batch liquid steel pouring out more times is available, which benefits foundries requirements of different size castings.HC’s patented technology

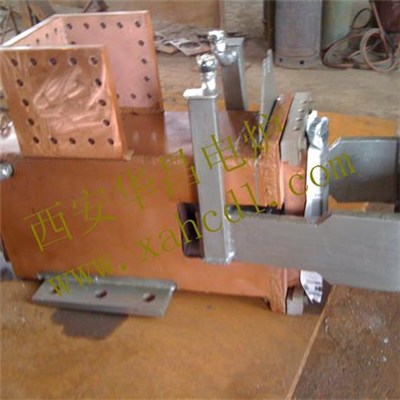

, is a kind of rod utilized to block the hole on ladle bottom, which can realize pouring through the bottom of ladle, make the pouring process easier, safer.Advantages of this kind mechanism: 1.Make one batch liquid steel with multiple pouring come true, which casting times is far more than sliding nozzle does. 2. The hot rod is mounted before pouring. Compared to cold rod, which will not be melted with liquid steel, and protect the plug rod from meltdown process, thereby, steel leakage can be avoided. 3. Implementation of hot rod is convenient, pressing down hand shank the pouring starts, otherwise, the pouring ends.6. Automatic temperature sampling system is available, so that the operation is more safe and convenient.7. HC’s furnaces are equipped with a variety of dust removal systems, can be based on environmental requirements of different countries support different forms of dust removal equipments.Huachang Metallurgical, one of the professional manufacturers, now brings you high quality and high precision ladle furnace from its professional factory. We are also a successful and experienced supplier and exporter of ladle furnace. We have qualified and experienced staff as well as advanced equipment, you can rest assured to get products with us.

Другие товары поставщика

|

|

|

DescriptionElectrode Holder is a special device for holding electrode. it should got the reasonableness of structure for water cooling in the condi... |

|

|

|

(1) Less volume,Website:, lighter weight, high efficiency and less power consumption. (2) Lower temperature, less dust around the furnace. (3) Simp... |

|

|

|

Usage:Charging basket is used for material charging. There are 4-5 charging baskets for prepare in the process of smelting. Strengths of HC chargin... |

|

|

|

Usage:Ladle refining furnace belongs to the secondary refining equipment, which typically to be used follows the primary melting furnace. Its main ... |

|

|

|

Bag filter is a kind of dry dust filtering device. After a period of time,due to the screen,collision,stranding,diffusion,electrostatic effe... |

Все товары поставщика

Похожие товары

|

|

электроизоляционные материалы и запчасти трансформатора |

Продавец: Longsper insulation technology(TIANJIN)CO.,LTD |

электрокартон

бумага с алмазным пунктиром DDP

бумага эпоксидный препрег DMD

крепированная бума... |

|

|

S тип сплава стальной нагрузочный элемент TSC 50kg для силовых измерительных систем loadcell тестер |

Продавец: Yixing City Sanwei Electric Manufacturing Co., Ltd. |

S тип нагрузки ячейки, напряжение и сжатиеХорошая симметрия вывода, компактная структура, простая... |

|

|

Round Rubber Washer |

Продавец: Ex-proof Cable Gland, EX Cable Glands, Explosion Proof Products, OEM Cable Gland Supplier & Manufacturer China |

O-ring

We are Sealing washer supplier

For use on cable gland entry threads,which is waterproof an... |

|

|

Mo Alloy Powder |

Продавец: Shanghai Laiwu Powder Material Co.,Ltd. |

Mo Alloy Powder,Pre Alloyed Powder |

|

|

Ni-Mo Alloy Powder |

Продавец: Shanghai Laiwu Powder Material Co.,Ltd. |

Ni-Mo Alloy Powder,Website: Alloyed Powder |