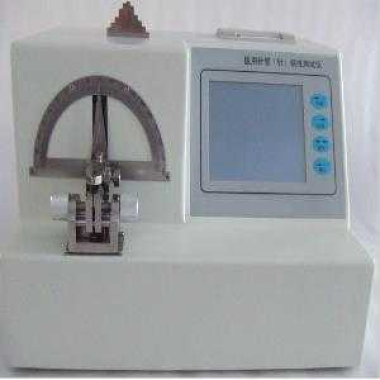

Contact Lens Oxygen Permeability Tester

The Contact Lens Oxygen Permeability Tester (Polarography Method) is a precision instrument designed to measure the oxygen permeability (Dk) of soft and hard contact lenses, hydrogel, silicone hydrogel, and other high oxygen permeability materials. The instrument provides accurate, repeatable measurements critical for lens manufacturers, laboratories, and research institutions. A complete measurement setup typically includes the main host, electrode assembly frame, electrodes, central thickness gauge, and a controlled temperature and humidity environment, ensuring compliance with international and national standards.

Application

(1) Measurement of oxygen permeability of soft contact lenses (hydrogel, silicone hydrogel).

(2) Evaluation of oxygen permeability in rigid or hard contact lenses.

(3) Quality control of contact lenses in manufacturing facilities.

(4) Research and development of new lens materials with enhanced oxygen permeability.

(5) Verification of compliance with regulatory standards for ophthalmic products.

(6) Laboratory testing of lens prototypes for performance evaluation.

Standards

(1) ISO 18369 – Ophthalmic optics – Contact lenses – Requirements and test methods.

(2) GB/T 11417 – Contact lens oxygen permeability measurement.

(3) ANSI Z80.20 – American National Standard for Contact Lens Oxygen Permeability.

(4) ISO 9913-1 – Ophthalmic materials – Oxygen permeability of polymer materials.

(5) ISO 9913-2 – Ophthalmic materials – Polarographic method for Dk measurement.

Features

(1) Dual input design supports simultaneous measurement of two test electrodes.

(2) Polarographic measurement ensures high accuracy and reproducibility.

(3) Compatible with soft, hard, hydrogel, silicone hydrogel, and other high Dk lenses.

(4) Complete system integration with host, electrode assembly, central thickness gauge, and temperature/humidity control.

(5) Precision temperature control (0.0–50.0°C) with 0.1°C resolution and ±0.2°C accuracy.

(6) Adjustable electrode excitation voltage (0.750 VDC) for polarographic measurements.

(7) Current measurement range with multiple gear options for low- and high-permeability lenses.

(8) Compact and portable design suitable for laboratory use.

Technical Parameters

| Parameter | Specification |

|---|---|

| Dual Input | Supports 2 test electrodes simultaneously |

| Power Supply | 210–250V AC, 5 W |

| Temperature Control | 0.0–50.0°C (Resolution 0.1°C, Accuracy ±0.2°C) |

| Electrode Excitation Voltage | 0.750 VDC |

| Electrode Specifications | Gold cathode Ø4 mm; Silver anode inner Ø5.75 mm, outer Ø12.75 mm |

| Size (W×D×H) | 356 × 190 × 102 mm |

| Current Zero Adjustment | 0–100 nA |

| Current Measurement Gears | 19.99 nA (±10 pA), 199.9 nA (±100 pA), 1.999 μA (±1 nA), 19.99 μA (±10 nA), 199.9 μA (±100 nA) |

Accessories

(1) Electrode assembly frame with two electrode slots.

(2) Gold cathode and silver anode electrodes.

(3) Central thickness gauge for accurate lens measurement.

(4) Constant temperature and humidity chamber.

(5) Calibration and adjustment tools.

(6) User manual and compliance certificates.

Test Procedures

Connect the electrodes to the dual input ports.

Place the lens sample in the electrode assembly frame.

Measure the central thickness of the lens using the thickness gauge.

Set the temperature and humidity to the desired test conditions.

Adjust the electrode excitation voltage to 0.750 VDC.

Zero the current using the current zero adjustment.

Start the polarographic measurement and record the current response.

Calculate the oxygen permeability (Dk) based on the polarographic data.

Repeat for a second sample or electrode if using dual input.

Maintenance Information

(1) Clean electrodes and assembly frame after each test to prevent contamination.

(2) Periodically calibrate the instrument using standard reference lenses.

(3) Check temperature and humidity control systems regularly for accuracy.

(4) Avoid exposure of the instrument to direct sunlight or high humidity.

(5) Replace electrodes when worn or damaged to maintain measurement precision.

(6) Store the instrument in a dry and dust-free environment when not in use.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| High Velocity Impact Testing Machine | Main Purpose To test the impact - resistance performance of glasses, goggles and face shields at a certain speed. Applicable Standards SNELL S... | |

| Goggles Puncture Resistance Testing Machine | The safety goggle puncture resistance testing machine is a device used to test the puncture resistance of safety goggles against impact from sharp ... | |

| Dry microbial penetration resistance tester | The Dry Microbial Penetration Resistance Tester assesses material resistance to dry bacteria-carrying particles (like human dandruff-sized). It tes... | |

| Dry Sand Rubber Wheel Wear Tester | Standard ASTM G65 JBT_7705 Applicable standards Dry and wet abrasive wear testing machines usually need to follow certain standards and specifi... | |

| Medical needle toughness tester | The Medical Needle Toughness Tester is designed to evaluate the mechanical strength and flexibility of medical needles under bending stress. It fea... |

Похожие товары

| Full-Body Garment Stress Tester,FZ/T 70015 | Продавец: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Продавец: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Продавец: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Продавец: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Продавец: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |