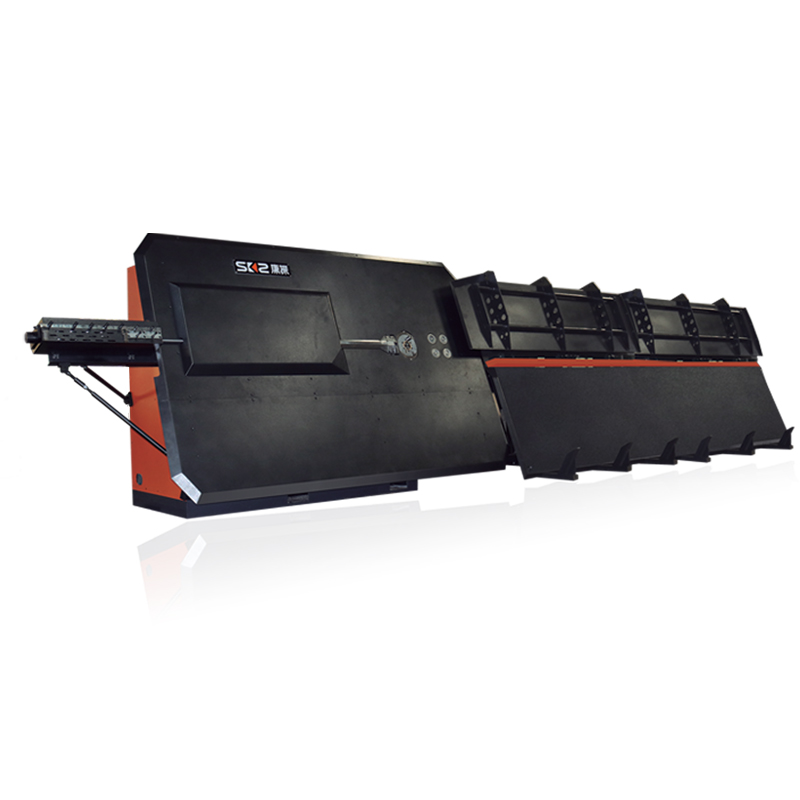

Easy operation Integrated Rebar Cutting

Model KQW50X Shearing part Max Shear Foree (KN) 1750 Co

|

Model |

KQW50X |

||||||||||||||||||||

|

Shearing part |

|||||||||||||||||||||

|

Max Shear Foree (KN) |

1750 |

||||||||||||||||||||

|

Conveying Speed(m/min) |

≤60 |

||||||||||||||||||||

|

Max Steel Strength (MPa) |

570 |

||||||||||||||||||||

|

Cutting Langth (mm) |

Manual |

800-12,000 mm |

|||||||||||||||||||

|

Automatic |

1500-12,000 mm |

||||||||||||||||||||

|

Culling Capacity |

(φ)(mm) |

10 |

12 |

14 |

16 |

18 |

20 |

22 |

25 |

28 |

32 |

36 |

40 |

||||||||

|

17 |

14 |

12 |

11 |

9 |

8 |

8 |

5 |

5 |

4 |

2 |

2 |

||||||||||

|

15 |

12 |

11 |

9 |

8 |

7 |

7 |

5 |

4 |

3 |

2 |

2 |

||||||||||

|

Average Pewer Consumption (KW/h) |

9 |

||||||||||||||||||||

|

Shearing Machine size (mm) |

25000*3500*2000 |

||||||||||||||||||||

|

Bending part |

|||||||||||||||||||||

|

Conveying speed |

40 (m/min) |

||||||||||||||||||||

|

Bending speed |

6-8r/min |

||||||||||||||||||||

|

Benders no° |

2 |

||||||||||||||||||||

|

Mobile bender move method |

Automatic |

||||||||||||||||||||

|

Power consumption |

10 (kwh) |

||||||||||||||||||||

|

1200 (mm) |

||||||||||||||||||||

|

Accuracy ol bending angle |

±1° |

||||||||||||||||||||

|

Conveyor load capacity |

1000 (KG) |

||||||||||||||||||||

|

Power supply voltage |

380V/50Hz/3phase |

||||||||||||||||||||

|

TotaL power |

30 (kw) |

||||||||||||||||||||

|

Total weight |

|||||||||||||||||||||

|

Bars diameter |

10 |

12 |

14 |

16 |

20 |

25 |

28 |

32 |

40 |

50 |

|||||||||||

|

Bending bars no° |

7 |

6 |

5 |

5 |

4 |

3 |

3 |

2 |

1 |

1 |

|||||||||||

STRUCTURE & CHARACTERS

Suitable for maximum steel bar length 12m.Maximum carrying capacity 1,500Kg.

12-m long feeding tracks consisting of motorized rollersLength could be specially designed

Pneumatic-mechanical cutting head.175 tons cutting capacity.Width of cutting blade: 300mm.Cutting frequency: 22 times/min.

12-m gauging and transfer tracks consisting of motorized rollersServo motor drived length measuring system.3 measuring system to maximize the gauging speed.

3 storage pockets at each side.Pneumatically operated, automatic stack.

- CONNECTING RACKu

Connect the

1 mobile bender1 fixed benderServo motor drivenPneumatically operated lifting device, delivery straight bars to bending mandrel and transfer shaped bars to storage rack.Pneumatically operated clamp device will fix the steel bars while bending.Shaped bars storage rack.

Touchable screen display.Optimized software, less scrap.Trouble shooting program to detect any failure or problem.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Wire Mesh Welding Machine | The intelligent steel mesh production robot KZH3300KX can be used for the production and welding of standard mesh and perforated mesh for prefa... | |

| cnc wire bending machine (KZ12CX) | This machine is a , which integrates straightening, positive bending and reverse bending forming and cutting four functions in one, steel bar hoo... | |

| Stirrup Bender Supplier | Stirrup bender is designed to complete straightening,bending and cutting on one machine. Coil is the prefer raw material choice .The machine ... | |

| Easy operation Integrated Rebar Cutting | Model KQW50X Shearing part Max Shear Foree (KN) 1750 Co Model KQW50X Shearing part Max Shear Foree (KN) ... | |

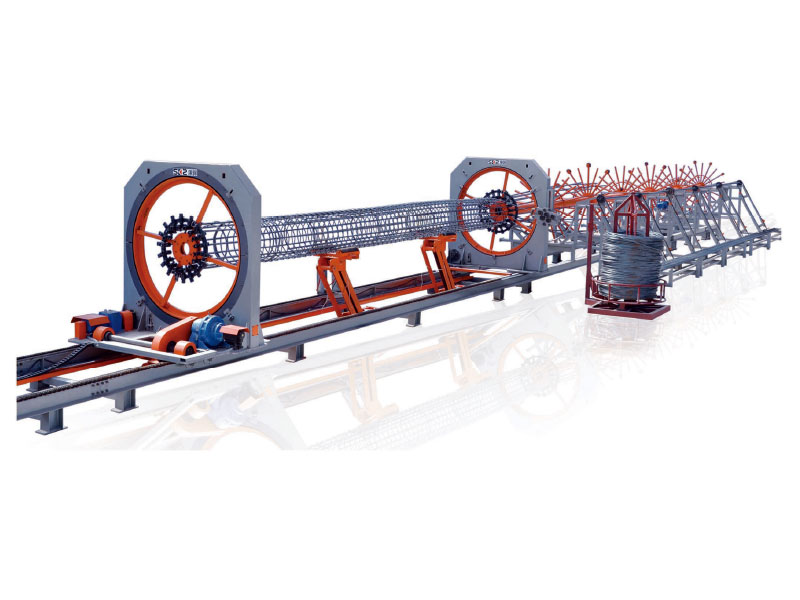

| Cage Making Machine Factory | The construction of the steel cage is the significant part of the basic bridge construction.In the past of the traditional construction, reinfor... |