The theoretical basis of zirconium-containing corundum brick

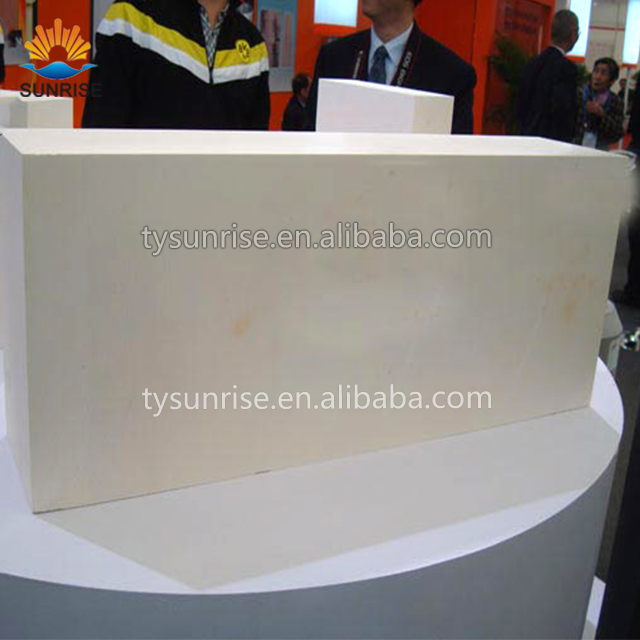

Zirconium-containing corundum brick Zirconia, zircon as raw material to produce corundum brick. Zirconia series products, zircon series products, zirconium mullite and zirconium corundum series of products belong to such products. According to the different production processes, zirconium-containing corundum brick is divided into sintered products, fused bricks and non-burning products. Zirconia-containing corundum brick has the characteristics of high melting point, low thermal conductivity and good chemical stability, and has good corrosion resistance to molten glass in particular.

The Zr-O system has several phases of oxygen in zirconium oxide and a non-stoichiometric oxide of the same melt. The stable compound of zirconium and oxygen is dioxide ZrO2. Zirconium dioxide has an ion radius ratio of 0.66, which is close to the limit of crystal coordination numbers 3 and 6. The zirconium cation is larger in size (0.082 nm) .In order to achieve the 8 coordination, oxygen ions are not as close as possible in the crystal lattice. Therefore, ZrO2 exhibits anomalous coordination. When its coordination number is equal to 7, one of the oxygen atoms occupies the space between two nodes of the AB crystal lattice. A lattice coordination and B lattice 4 coordination, High temperature by ions in the lattice node thermal motion occurs longer bond length is due to oxygen ions from the unit space transition to the A or B position knot preclude. Anion vacancies at the same time to achieve the 8 coordination.

The properties of Zr-bearing corundum bricks depend on the nature of ZrO2. Density and Stabilization The melting point of zirconia is 2677 ℃ and the temperature is 2500 ℃. The bulk density fluctuates 4.5 ~ 5.5g / cm3 due to the purity of the raw materials and the manufacturing method. The bulk density of compact zirconium corundum brick can reach 5.75g / cm3. Sintered zirconium corundum brick and liquid glass can not afford chemical reaction. Caustic solutions, carbonate solutions and acids (except concentrated H2SO4 and HF) do not react chemically with zirconia. ZrO2 has high structural strength and as a lining of the hot surface has the ability to work at 2200 ~ 2450 ℃ temperature.

Zirconia corundum brick high mechanical strength, and strength has been maintained to 1300 ~ 1500 ℃. The thermal conductivity of ZrO2 is much lower than the thermal conductivity of all other oxide materials. The use of ZrO2 this feature can be made of high temperature insulation layer.

Other supplier products

All supplier products

Same products