Catalytic combustion

-

Catalytic combustion is an efficient waste gas treatment method. Its main principle is to use a catalyst to oxidize and decompose combustible substances in the waste gas at a lower temperature (usually 200-400c). This method has low energy consumption, simple operation, safety and high purification efficiency, and is very suitable for the application of chemical industry, painting, insulating materials, coating production and other industries.

The basic principle of catalytic combustion is as follows: catalytic combustion, with the help of a catalyst, organic waste gas at a low ignition temperature, flame less combustion, and oxidation decomposition into carbon dioxide and water, at the same time release a large amount of heat.

Catalytic combustion process can be divided into:

The preheating type is the most basic process form of catalytic combustion. When the temperature of organic waste gas is below 100℃ and the concentration is low, the heat cannot be self-sufficient, so it needs to be heated in the preheating chamber before entering the reactor. Gas or electric heating is usually used to heat the exhaust gas to the ignition temperature required for the catalytic reaction. The purified combustion gas is heat exchanged with the untreated waste gas in the heat exchanger to recover part of the heat.

Organic waste gas has a high temperature and a high content of organic matter, so it is usually only necessary to set an electric heater in the catalytic combustion reactor to be used when starting combustion. The heat generated by part of the purified gas can be recovered through the heat exchanger, and the thermal balance can be maintained under normal operation without adding heat.

Send product request

Other supplier products

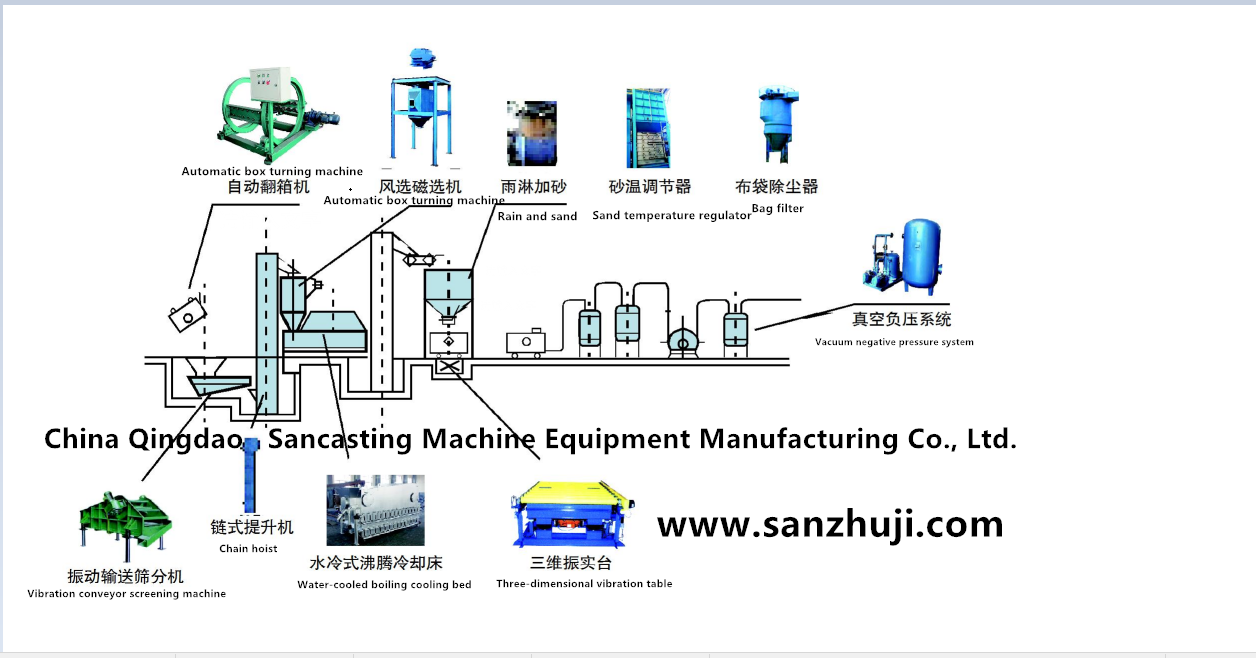

| Coated sand shell profile process drawing | The process of shell type steel filling (dry sand) is to put the shell type into the barrel and fill the steel balls (dry sand) around the barrel... | |

| S86 series boiling cooling bed | This series of equipment is a continuous cooler, loose old sand into the cooling bed, in the case of high pressure fan strong blast, boiling stat... | |

| 28GN metal track shot blasting machine | 28GN metal track shot blasting machine | |

| L series falling sand cooling roller | When the mold of the sand box is rotated to a certain height, it falls to the bottom of the simplified box by its own weight. Under the mutual im... | |

| L12 Series Inertial Vibration Shaker | Advanced and reliable double vibration motor self-synchronization and high reliability of vibration resistant welding structure and process; The... |

Same products

| MONSA® DDAC-50 | Seller: Guangzhou Monsa Chemical Co., Ltd | INCI name: MONSA® DDAC-50 It functions by causing the cell membrane of bacteria to rupture... | |

| MONSA® DCA-50 | Seller: Guangzhou Monsa Chemical Co., Ltd | INCI name: disodium cocoampho diacetate Disodium cocoamphodiacetate for skinis a very mild amp... | |

| MONSA® CTAC-50 | Seller: Guangzhou Monsa Chemical Co., Ltd | INCI name: Cetyl Trimethyl Ammonium Chloride Cetyl Trimethyl Ammonium Chloride is an ammonium ... | |

| MONSA® CTAC-30 | Seller: Guangzhou Monsa Chemical Co., Ltd | INCI name: Cetyl Trimethyl Ammonium Chloride 30% Cetyltrimethyl ammonium chloride30% is mainly... | |

| Common Rail Injector | Seller: DIP (DIESEL INJECTION PARTS) PLANTS | Item: Diesel Fuel Injector Model No: MOQ: 1pc Material: SteelPackage Deta... |