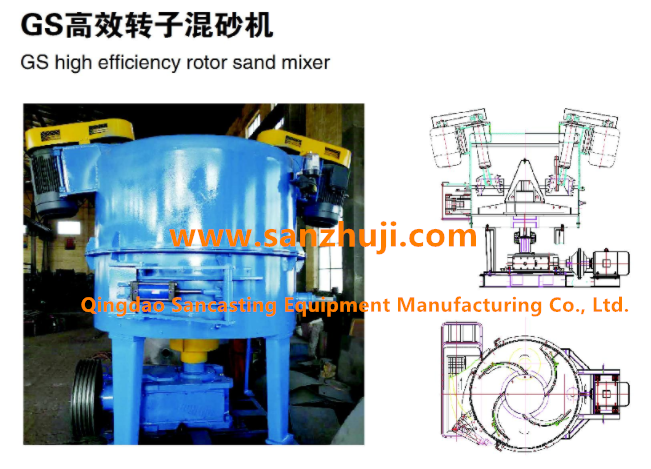

GS high ficliency rotor sand mixer

Low speed scraper and medium speed rotor are best matched, the sand mixing capacity is large, the sand mixing ability is strong, the sand comprehensive performance is good.

Diabase cast stone, carbonized dock surfacing welding, no. 2 filler and other new materials, greatly improve the life of vulnerable parts.

Alloy steel gear, no. 1 packing, lubrication control machine, ensure the balance and reliability of the transmission system.

Symmetrical open access door greatly facilitate maintenance and cleaning.

The steel base makes the machine easy to install.

Send product request

Other supplier products

| S56 series vibration regeneration machine | S56 series vibration re - vitality is the company's absorption of foreign equipment of the same kind of advanced technology. The resin sand was suc... | |

| S89 series water- cooled boiling cooling bed | The water-cooled boiling cooling bed is the most widely used cooling equipment in the sand treatment system of epc. Although it has complex structu... | |

| S83 series double- -disc stiring cooler | This machine is mainly used for the cooling of old clay sand. The sufficient movement makes the temperature, humidity and composition of the old sa... | |

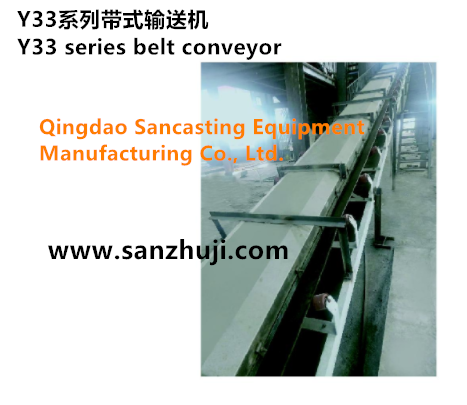

| Y33 series belt conveyor | This series of belt conveyor is a new type of belt conveyor designed according to the characteristics of the casting shop, mainly used for casting ... | |

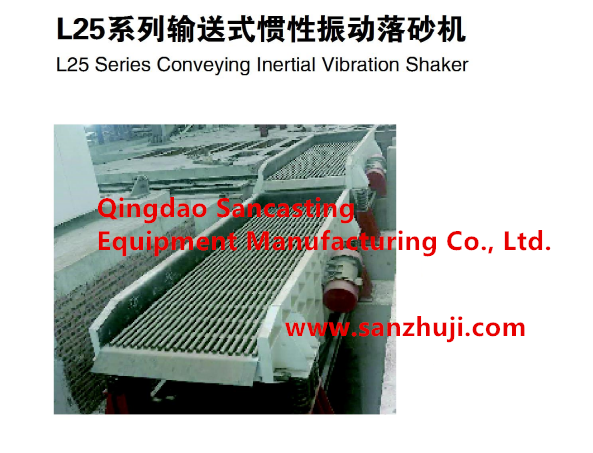

| L25 Series Conveying Inertial Vibration Shaker | The role of this shakeout machine is to separate molding sand castings by vibration, which is the first link of the old sand treatment system and t... |

Same products

| Micronized polypropylene wax for injection moulding | Seller: Syntop chemical Co.,Ltd. | The incorporation of polypropylene micronized wax into injection moulding processes delivers the ... | |

| Drum Type Mobile Mixing Station | Seller: Yousheng Machinery Equipment Co.,Ltd | Drum Type Mobile Mixing Station Drum Type Mobile Mixing StationPortable Drum Concrete Batch Plan... | |

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | Seller: XIUCHENG RFID | Size:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transf... | |

| Micronized wax used for industrial paint processing | Seller: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | Seller: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... |