Sheet Metal Fabrication

Sheet metal is a comprehensive cold working process for metal sheets (usually below 6mm), including shearing, punching/cutting/compounding, folding, riveting, splicing, forming, etc. Its notable feature is the uniform thickness of the same part. The basic equipment of sheet metal technology includes a shearing machine, CNC punching machine, laser, plasma, water jet cutting machine, bending machine, drilling machine, and various auxiliary equipment. In addition, custom metal fabrication servicesprovide metal processing with aluminum sheet metal panel fabrication, stainless sheet metal fabrication, and titanium sheet metal fabrication, etc.

Welding

According to different materials and processes, use corresponding welding methods, including laser welding, gas shielded welding, argon arc welding, etc.

Welding

Bending

CNC bending machine processing, can make various types of bending products according to customer requirements

Bending

Cutting

Use laser cutting, plasma cutting, water cutting and other methods to process materials

Cutting

Metal Spinning

The spinning method can be used to complete the deep drawing, flanging, necking, bulging and curling of rotating bodies of various shapes.

Metal Spinning

CNC Punching

Used for all kinds of metal sheet parts processing, can automatically complete a variety of complex hole types and shallow stretch forming processing at one time.

CNC Punching

Processable Materials for Sheet Metal Fabrication

Copper

Magnesium

Stainless Steel

Carbon Steel

Alloy Steel

Zinc Alloy

Aluminium Alloy

ABS

Aceta

Acrylic

Carbon Fibe

Fiberglass

Nylon

Polycarbonate

Spring Steel

PTEF

PVC

Neoprene

Polyethylene

Polypropylene

Polystyrene

Rubbe

Silicone

NBR

Laser Welding

Welding Parts

Laser Cutting

Dust Cover

Radiating Plate

Radiating Plating

Lamp Shade

Advantages of Sheet Metal Fabrication

Not Limited By Material Properties

Sheet metal processing can quickly process aluminum alloy plates and cemented carbides and can cut without deformation no matter how high the hardness is. And its processing flexibility is very good, not only can process any kind of graphics but also can cut pipes and other strange-shaped materials. And most non-metallic materials can also be cut quickly and efficiently, so CNC sheet metal fabrication will not be restricted by any material properties.

Fast Processing Speed

The most significant advantage of sheet metal processing technology is the fast cutting speed, and it will not be limited by the number of processing. However, the sheet metal cutting service is more suitable for the processing of special-shaped workpieces in the process of processing because it does not need to waste time to replace the tool, which effectively increases the processing speed; to a certain extent, its processing speed and maximum positioning speed are lower than the speed of wire cutting.

The Effect Is Obvious

Laser cutting in sheet metal processing belongs to non-contact cutting, and its cutting edge is affected by heat to a small degree, which can avoid the adverse effect of thermal deformation of the workpiece. Moreover, it can completely avoid the collapse of the material when the material is punched and cut. Generally, the cutting seam does not require secondary processing, which improves the work efficiency to a certain extent; not only that, its cutting head will not contact the material surface, thus efficiently ensure that the workpiece is not scratched.

Sheet Metal Fabrication FAQS

When A Longer Workpiece Is Bent, The Angle Will Be Large At One End And Small At The Other End

Reason: In this case, there are generally the following situations: the thickness of the material is uneven, one end is thick, and the other end is thin. The mold wears unevenly, and the two ends are different in height. The middle block is not balanced and not at the same level.

Solution: feedback to laser or NCT to make it pay attention to the choice of material, replace the mold, or adjust the middle block.

Several Reasons For Bending And Cracking Of Aluminum Plates

Linear Standard For Bending In Sheet Metal Processing

What Measures Should Be Taken To Protect The Entire Sheet Metal Processing Process

ETCNis a professional machining and manufacturing company, we provide CNC machining, metal stamping, stainless steel sheet custom cut, custom steel sheet, aluminium fabrication sheet, custom stainless & sheet metal, custom stainless sheet metal, cnc manufacturing services, custom machiningand etc. Want to know more? Please contact us.

Send product request

Other supplier products

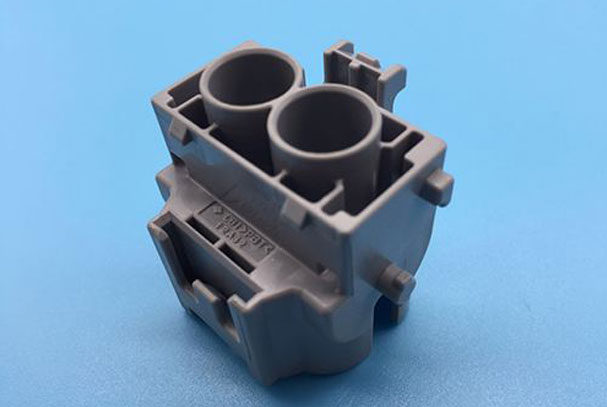

| Plastic Injection Molding | As a cnc machining companyin china, ETCN cnc machining and manufacturingcovering different fields in china cnc machining and manufacturing services... | |

| Stretch Forming | Sheet metal stretch formingis a technology to stretch the mental into different shaped mental parts. It also will improve the structure of the unlo... | |

| CNC Boring | CNC boringis used for the shaft sleeve in the transmission shaft of large equipment, and the tolerance of the bearing position is +0.03mm. After we... | |

| Welding | Medical supplies, laser welded forming, beautiful appearance, firm, flat welding seam, no welding rod, and flux welding sheet metalis needed. As a ... | |

| Welding | Medical supplies, laser welded forming, beautiful appearance, firm, flat welding seam, no welding rod, and flux welding sheet metalis needed. As a ... |