Selective Laser Sintering

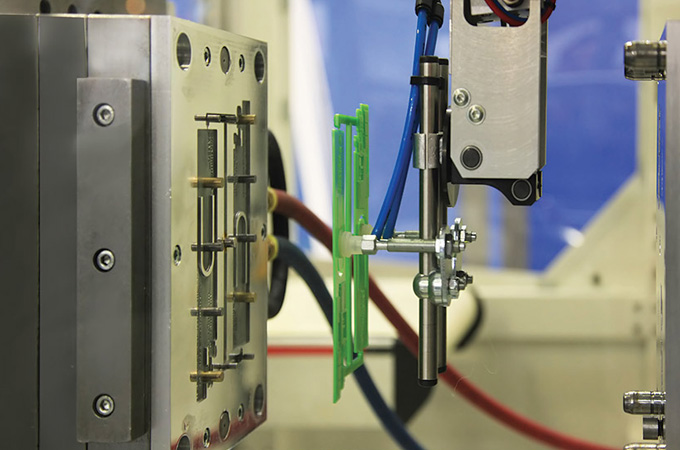

Founded in 1978, Zhongde is a professional injection molding supplierfocusing on OEM & ODM customized services. Based on 40 years technology deposition, we have developed a one-stop solution from mold designing and rapid prototyping to mass production. Our manufacturing capabilities include plastic injection molding service, compression molding service, CNC machining service, metal stamping service, 3D printing service, custom molding service,etc.

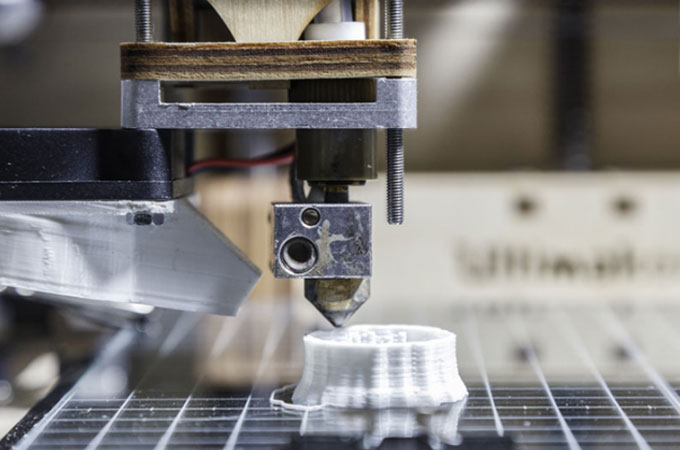

Selective Laser Sintering(SLS) is an industrial 3D sintered laser printingprocess ideal for manufacturing end-use parts. In SLS, a laser selectively sinters polymer powder particles, fusing them together and building a part layer-by-layer. From prototyping to small-batch production, our 3d laser sintering printing facilities will allow you to produce highly accurate parts with quality and strength comparable to injection molding.Now the selective laser sintering costis low.

SLS produces functional plastic parts with isotropic mechanical properties that can be used for detailed prototyping or end-use low-volume production.

Guideline of Fused Deposition Modeling

Size of Selective Sintering

Below table shows the size of Fused Deposition Modeling parts we usually make. If you need a larger size, we can also help you achieve it.

|

Standard capabilities |

Description |

|

Maximum build size * |

300 x 300 x 300 mm (11.8” x 11.8” x 11.8”) |

|

Lead time * |

6 business days |

|

Dimensional accuracy |

± 0.3% with a lower limit of ± 0.3 mm (± 0.012”) |

|

Layer thickness |

100 μm |

* For expedited lead times or parts that exceed the maximum build size contact

Available Materials of Selective Laser Sintering

In addition to the general materials listed below, Zhongde can also modify the materials according to the special needs of customers. Our professional engineers will adjust the raw material formula to meet the unique conditions of use.

|

Material |

Description |

|

Nylon 12 (PA 12) |

SLS nylon is a robust thermoplastic with all-around excellent physical properties, ideal for functional prototypes and end-use applications. |

|

Glass-filled Nylon (PA 12 GF) |

Glass-filled SLS nylon is reinforced with glass beads creating parts with higher stiffness and thermal stability than standard nylon. |

|

TPU / TPE / TPA * |

Thermoplastic elastomers combine high elasticity and strength with good chemical resistance, making them ideal for functional, flexible parts. |

These materials are available by contacting

Design Guidelines of Selective Laser Sintering

The following table summarizes the recommended and technically feasible values for the most common features encountered in 3D printed parts.

|

Feature |

Recommended size |

|

Unsupported walls |

|

|

Supported walls |

|

|

Minimum detail size |

|

|

Minimum hole size |

|

|

Moving parts |

|

|

Assembly clearance |

|

|

Maximum wall thickness |

20 mm (0.8''). Thicker parts must be hollowed with and at least two escape holes for powder removal with a min. diameter of 8 mm (0.3''). |

Available Surface Finishes of Selective Laser Sintering

Additional post processes can be applied to improve the appearance or mechanical properties of parts produced with SLS.

|

Finish |

Description |

|

As printed |

As printed SLS parts are typically white or stone grey in color with a smooth surface and a powder texture and without visible layers. |

|

Dyed |

SLS parts can be dyed by immersing in a warm color bath to a variety of colors. The color penetration reaches an approximate depth of 0.5 mm and covers all surfaces. |

|

Tumble smoothing * |

The parts are placed in a tumbler that contains small ceramic chips, gradually eroding its surface down to a polished injection molding-like finish. |

|

Bead blasting |

Bead blasting (shot pinning) adds a uniform matte or satin surface finish on a 3D printed part. * |

|

Spray painting * |

SLS parts can be spray painted white, black or to a specified RAL or Pantone color. |

|

Water tightening * |

SLS parts are vacuum impregnated with resin, sealing all internal porosity and ensuring water tightness. |

|

Metal plating * |

Electroplating (nickel, copper or gold) is an ideal solution for parts that require a metallic appearance, without the high costs associated with metal 3D printing. |

Send product request

Other supplier products

| China Custom CNC Machining Parts | Zhongde provides professional and reliable custom injection molding services, and makes all the molds in-house. Our completed production line and v... | |

| Plastic Injection Molding | Founded in 1978, Zhongde is a professional injection molding supplier focusing on OEM & ODM customized services. Based on 40 years technology d... | |

| Plastic 3D Printing Parts | The following are some of the3d printing small plastic partswe have made for our customers. They are only for displaying our products range and sha... | |

| Custom Compression Molding Service | Compression molding is a method of forming plastic or rubber in a closed cavity by heating and hot pressing. It is a good choice for manufacturing ... | |

| CNC Machining Service | Machining refers to the process of changing the dimensions or performance of the workpiece through mechanical equipment. Zhongde, a reputable fast ... |