Cooling Tower Filling

Our cooling tower incprovides cooling tower filling, drift eliminator, fan, motor, gearbox, belt reducer, spray nozzle, sprinkler head, float ball, air inlet louvers, etc... Whatever cooling tower partsyou need, you will find them in our cooling towers LLC AUVC.

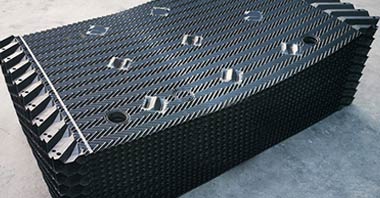

As a cooling tower fills manufacturer,as well as pvc fill for cooling tower suppliers,we supply different materials for thefills with good cooling tower pvc fills pricesuch as PP and PVC. The honeycomb design principle is adopted, which is an important part of cooling tower. The function of fill in cooling tower is to increase heat dissipation, prolong the residence time of cooling water, increase heat exchange area, and distribute water evenly.

Types Of Fills In Cooling Tower

Cooling Tower Filling For Mesan

Product Description: cross flow tower, can only be suspended, tilt angle 5.5 degrees, suspended. It is suitable for the maintenance and renovation of cooling towers of Marley, Xinling, Yuanheng and Lanxun brands.

Cooling Tower Filling For BAC

BAC cooling tower filling is one of the most important parts of the heat exchange process of the cooling tower. It is also the main part to improve the efficiency of cooling tower and ensure the economy and safe operation.

Cooling Tower Fills Specification

Feature 1: The cooling fill media in cooling toweradopts inclined suspension installation and the bottom of the filling is suspended. This way the cooling tower will not deposit debris and the water will flow smoothly, preventing algae and bacteria from growing.

Feature 2: No glue bonding, no deformation, no embrittlement, effectively solve the problem of filling scaling. The old installation method used glue bonding, and the filling was stacked in the cooling tower. When it was used, the bonding point of the filling was easy to scale, which accumulated over time and collapsed after serious bending deformation, thus affecting the cooling performance.

Feature 3: Increase the effective air intake area. More steel frame is needed to support the bottom of the bonded filling, which reduces the effective air inlet area of the filling, while the suspended installation of the fill media in the cooling tower does not need to support the steel frame.

Feature 4: Filling installation, transportation, and maintenance are simple and convenient.

Advantages Of Cooling Tower Filling

- ℃ - 35 ℃.

Attention Requirements For Cooling Tower Filling

Advantage of Cooling Tower Filling

- tower fillare PVC and PP, with good toughness, no white line and aging resistance.

Send product request

Other supplier products

| Cross Flow Cooling Tower | Cross flow cooling tower is an induced draft cross flow cooling tower that can cool water. The water flows vertically from the top of the tower, an... | |

| Cooling Tower Fan For Marley | The fan of Marley open cooling toweradopts hollow aluminum alloy extruded blade, and the fan is adjustable angle type, which can meet the different... | |

| Cooling Tower Drift Eliminator | Zhejiang Aoshuai Refrigeration Co., Ltd. is a professional cooling tower companythat supplies FRP cooling towerand cooling tower spare parts. Indus... | |

| 40 Ton Cooling Tower | Closed Circular Cross Flow Cooling Tower(AHC) It refers to a cooling tower in which the cooling hot water passes through the packing from top to b... | |

| Cooling Tower Belt Reducer | Cooling tower belt reducer is a kind of deceleration equipment of cooling tower. The outer part of the main body is provided with a corresponding b... |