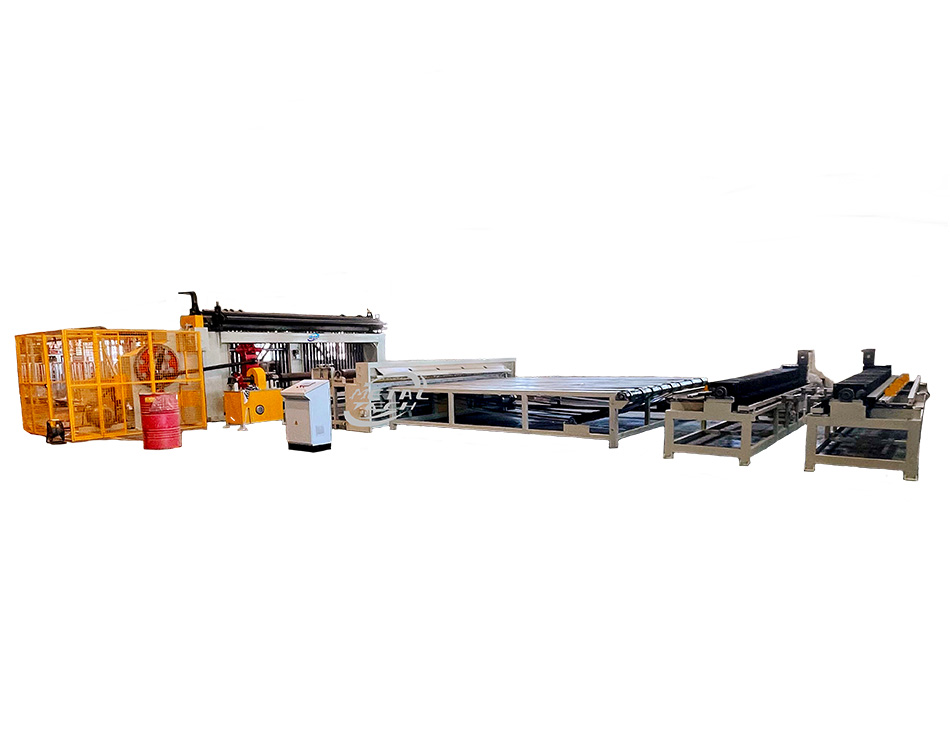

Hot Dip Galvanizing Production Line

Hot dip galvanizing line is main for wire galvanizing and ready for gabion machine, chain link fence machine, barbed wire making machine, wire mesh welding machine, etc.

Metal Tech has professional team can design for different requirement of the finished wire of different wire diameter, different zinc coating thickness and different capacity. So that clients should make sure the wire diameter&wire type, zinc thickness and yearly capacity.

Specifications of HOT DIP Galvanizing Production Line

|

Production Capacity for Different Diameter |

|||||

|

Diameter (mm) |

DV (mm*m/min) |

Single Line Production Capacity(Ton/24h) |

30 Lines Production Capacity(Ton/24h) |

||

|

1 |

Φ1.5 |

80 |

≈53 |

≈1.0 |

≈30.0 |

|

2 |

Φ2 |

80 |

40 |

45 |

|

|

3 |

Φ2.5 |

80 |

32 |

51 |

|

|

4 |

Φ3 |

80 |

≈26 |

≈2.0 |

≈51(25 Lines) |

|

5 |

Φ4 |

80 |

20 |

||

|

Remark:1. Production Capacity is calculated as 24 hours/day.2. The production line capacity takes Φ 2.5mm steel wire as the standard wire diameter. When the steel wire diameter is greater than Φ 2.5mm, the number of threading wires should be reduced. |

|||||

Advantages of HOT DIP Galvanizing Production Line

Metal tech Hot dip galvanizing line use high-quality material parts ,such like NSK bearing, PARKER hydraulic system , quenching and brazing half gear etc,strict quality management all these guarantee superior quality and long performance Hot dip galvanizing line life, also we have different quality and different zinc coating mode can meet all requirement from client.

Production Process of HOT DIP Galvanizing Production Line

Wire pay-off device(vertical)→ Straightening→ LPG Annealing→ Natural air cooling→ Water cleaning→ Turbulent smoke-free cleaning→ Water cleaning→ Plating flux→ Drying→ Hot Dip Galvanizing→ Wiping→ Cooling→ Wire take-up the device(vertical)

Gabion box machineis a professional steel wire drawing machine manufacturer,we provide weld mesh manufacturing machine, multi wire drawing machine, hot dip galvanizing line, automatic chain link fencing machineand etc. Want to know more? Contact us.

Send product request

Other supplier products

| Gabion Machine Manufacturer | Gabion machine, also known as gabion mesh machine, its purpose is to produce wire mesh, and then the complete net is folded and connected into a co... | |

| Gabion Mesh Weaving Machine | Gabion Mesh Weaving Machine Gabion wire mesh machine is a kind of wire mesh machine to produce hexagonal wire mesh, then to fold and connect each o... | |

| Bolt Making Machine | Aluminium Tower Bolt Making Machine Metal tech automatic bolt making machine, adopting multi station cold heading forming technology, mainly used... | |

| Fully Automatic Chain Link Fence Machine | Chain link fence machine can be called Diamond wire mesh as well. there are four types of fully automatic chain link fencing machines: 1. Double wi... | |

| High Speed Nail Making Machine | High Speed Nail Making Machine Metal Tech high speed nail mesh wire making machine manufacturers is for making nails with large batch, high precis... |

Same products

| YC160W Wheel excavator YC160W | Seller: Guangxi Yuchai Equipment Technology Co., Ltd | YC160W Wheel excavator YC160W wheel excavator is a new generation of full hydraulic wheel excavat... | |

| Yuchai U20 mini excavator | Seller: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai U20 mini excavator Improvements in Over 80 Details: Tailless Excavator U20 is a Yuchai ... | |

| Yuchai YC80 small excavator | Seller: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai YC80 small excavator International brand engine It is equipped with Yanmar 4TNV98C natur... | |

| Top Type Hydraulic Breaker | Seller: Guangxi Yuchai Equipment Technology Co., Ltd | Top Type Hydraulic Breaker With the higher restriction of blasting control,hydraulic breakeris w... | |

| S35-Electric Skid Steer Loader | Seller: Guangxi Yuchai Equipment Technology Co., Ltd | S35-Electric Skid Steer Loader Yuchai S35 Electric Skid Steer Loaderis compact and flexible, des... |