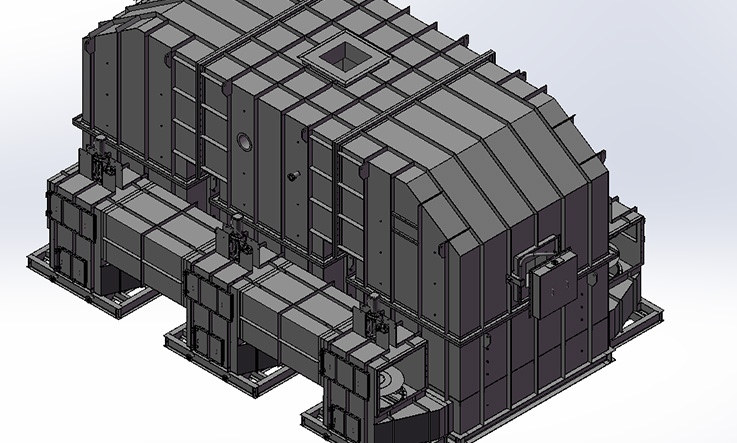

Regenerative Thermal Oxidizer (RTO)

Our Regenerative Thermal Oxidizer (RTO) uses ceramic media to recover upwards of 97% of the available energy, Widely considered to be the most energy-efficient oxidizer. Its ability to repurpose the thermal energy generated during operation to reduce operating costs and energy consumption of the system itself make the RTO so popular widely. The regenerative component makes it capable of fuel-free operation at very low VOC concentrations.

Benefits of the RTO Oxidizer

System pressure drop resulting in reduced electrical consumption

Multiple designs for easier and faster installation

Greater system flexibility and versatility

High reliability and long-life expectancy (15-20 years+)

Design Features of RTO Oxidizer

Pre-assembly, wiring, and testing as much as possible prior to shipment

Can handle process flows up to 25% Lower Explosive Limits (LEL) with self-sustaining LELs as low as 3%

The burner is sized for full flow, zero process VOC emissions so that the RTO can maintain temperature and VOC destruction efficiency over the entire range of process operation

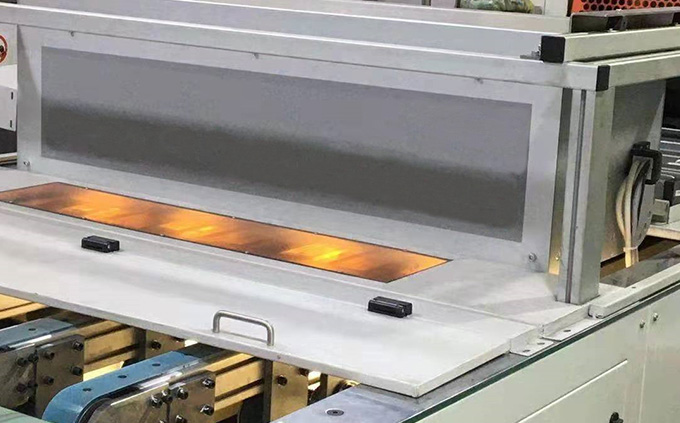

Bake-out capabilities designed to remove organic particulate buildup

Hinged access doors for ease of maintenance

Variable Frequency Drives (VFDs) to support high volumetric turn-down during low-process and idle conditions

Compliance with FM Global and other international certifications

RTO Oxidizer Air Flow Range & Efficiency

Air Flow Range:3,000-70,000 SCFM (4,815-112,350 Nm3/hr) / Single Unit,70,000-500,000 SCFM (112,350-802,500 Nm3/hr) / Multiple Units

Concentration Range:0 – 25% LEL

Destruction & Removal Efficiency:99%+

RUIYUAN Printing Equipment Co. Ltd., is aprofessional regenerative thermal oxidizer manufacturers, we provide regenerative thermal oxidizer for sale, regenerative thermal oxidation, regenerative thermal oxidiser, rto oxidizer, recuperative thermal oxidizer, pressing stamp, colour printing machine, etc. Want to know regenerative thermal oxidizer costor more? please contact us.

Send product request

Other supplier products

| RYYT 452 Series Metal Decorating Machine | RYYT 452 series multi color offset printing machineis the market and technology leader in the field of metal decorating presses. RYYT 452 series mu... | |

| Drying Oven | As one of the professional industrial drying oven manufacturersin China, RUIYUAN continues technological innovation to create the best value for al... | |

| Metal Heat Transfer Thermal Oxidation Device(TNV) | Metal Heat Transfer Thermal Oxidation Device(TNV) Metal heat transfer thermal oxidation device(TNV)dftois used to purify industrial waste gases co... | |

| CTP Computer to Plate Printing Machine | CTP (Computer To Plate) refers To Computer direct Plate making, which uses laser scanning To record digital page information on the Plate, and then... | |

| Metal Printing and Coating Online Monitoring | The online monitoring technology is suitable for metal printing and coating production line, which greatly improves the yield and reduce metal shee... |

Same products

| Micronized polypropylene wax for injection moulding | Seller: Syntop chemical Co.,Ltd. | The incorporation of polypropylene micronized wax into injection moulding processes delivers the ... | |

| Drum Type Mobile Mixing Station | Seller: Yousheng Machinery Equipment Co.,Ltd | Drum Type Mobile Mixing Station Drum Type Mobile Mixing StationPortable Drum Concrete Batch Plan... | |

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | Seller: XIUCHENG RFID | Size:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transf... | |

| Micronized wax used for industrial paint processing | Seller: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | Seller: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... |