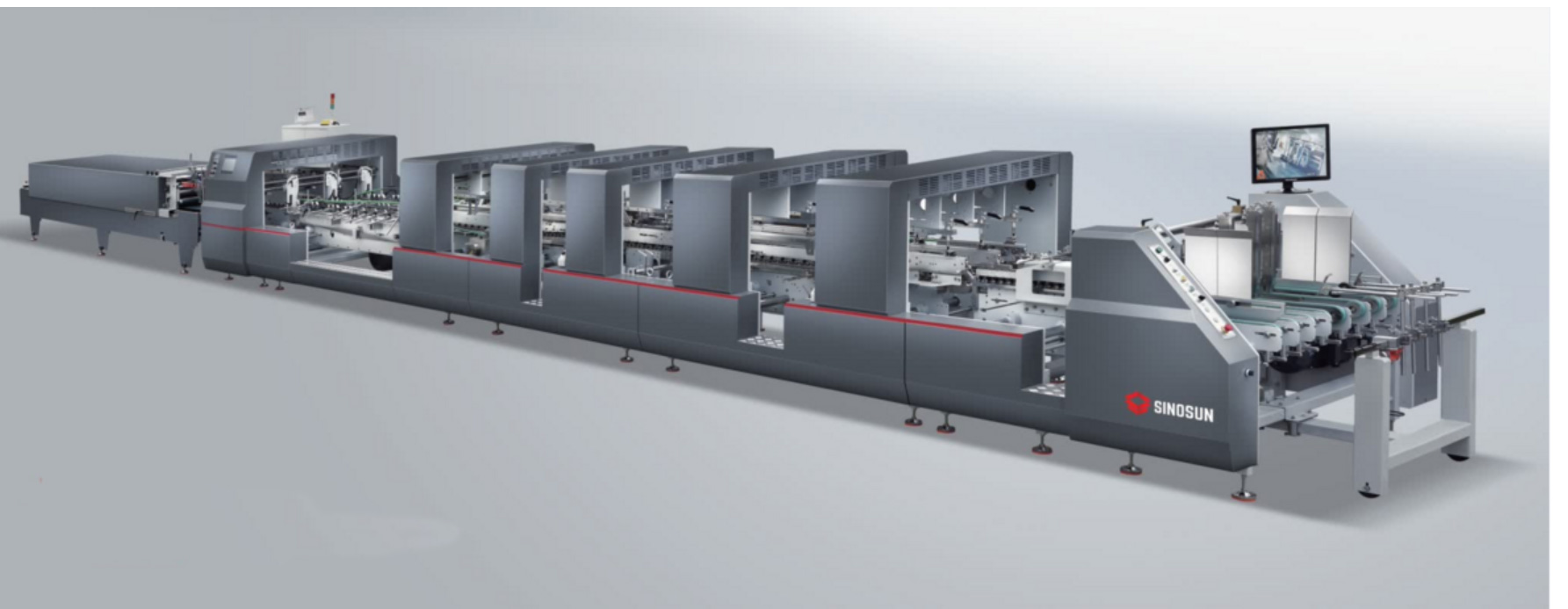

Automatic Stacker Machine

As one of the professional packaging machinery suppliers, Our product line covers a wide range of products including die-cutting machine, film lamination machine, folder gluer machine, grey board slitting machine, paper bag machine, window patching machine, flute lamination machine, carton forming machine, etc., which can be used for food packaging, electronic packaging, daily chemical packaging.

Automatic Stacker Machine is a flute laminating machine supporting product, which comprises a feeding station, a tumbling table and a receiving station which are connected in series, wherein the paper collection stack and the paper counting stack into the counting pile into the turntable. The use of flip inside mechanism will count the stack in turn once again turned over to the top of the flip table, and then push the feeding device into the top of the receiving station. The Paper is laid on the pallet of the receiving station and is fully automated for paper counting, paper rollover and paper stacking, paper with flattened paper and a significant reduction in manpower requirements and effective pick-up efficiency and other effects reduce the strength of manual delivery.

Our company offers stacker machine for salewith a good stacker machine price. we also provide other high quality products for customers, such as stacker machine for warehouse, conventional turning machine, automatic turning machine, pallet stacker machine, etc.

Features of Automatic Stacker Machine

The high-end intelligent type can be equipped with an automatic tray, which can automatically exit the warehouse and connect with the logistics assembly line, thus greatly reducing the labour intensity of employees, more convenient operation and greatly improving the paper.

Function of Auto Stacking Machine

Adopting A Newly Designed Delivery Bin

The machine adopts a newly designed delivery bin, which completely solves the indentation caused by the collision of paper and metal in the production process.

Conveying Mechanism

A new belt conveying mechanism was added to replace the old paper-feeding mechanism, which solved the crease caused by the paper being overweight and pushing the paper.

The High-end Intelligent Type

The high-end intelligent type can be equipped with an automatic tray, which can automatically exit the warehouse and connect with the logistics assembly line, thus greatly reducing the labour intensity of employees, more convenient operation and greatly improving the paper.

Send product request

Other supplier products

| 1050 ES Automatic Stripping Die-Cutting Machine | 1050 ES automatic waste stripping machinecould be creasing, die-cutting, and stripping after printing products, such as more than 80g/m² paper... | |

| Folder Gluer Machine | BoxFolder Gluer Machine Growing has been devoting itself to the technical creation and reliable design of folding and glueing with the spirit of p... | |

| Flute Lamination Machine | As one of flute laminator manufacturers, GEOWING has developed three flute laminatorabiding by the concept of intellectualization, digitization, fu... | |

| Automatic Highspeed Flute Lamination Machine | As one of the packing machine manufacturers, we provide die cutting and creasing machine, automatic flute laminator, automatic cold lamin... | |

| Automatic Front-lay Flute Laminator | STM Series Automatic Front-lay Flute laminator is used to paste the colour-printing surface paper together with the bottom paper (cardboard or corr... |