Shaft

CIC’s equipment includes leading standardized heavy equipment and machinery products and related heavy machinery services, which can be sold directly to end customers, business partners, and EPC projects. As a professional heavy equipment companies, CIC serves multiple roles, such as, cement machinery suppliers, mining machinery manufacturers, grinding mill manufacturer, rotary kiln manufacturer, rotary dryer manufacturer, sludge dryer manufacturer and so on.

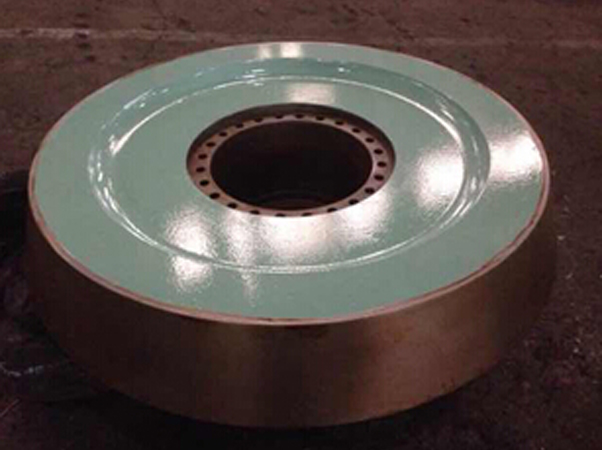

CIC is a more than 50 years manufacturer and reputed supplier of forged pinion and pinion gear shaftwidely used in various machinery equipments in the fields of mining, metallurgical, chemical industry, construction and so on. CIC possesses professional design team, advanced equipment and detecting method, strict quality control system to meet all the customized requirements of forged pinion or shaft and pinion. Excellent performances, high quality and competitive price will make you rely on us and choose us. As one of the pinion shaft manufacturers, CIC has manufactured many kinds of forged parts, include forged pinion, forged roller, support roller forged shaft, thrust roller forged shafts,bevel pinion shaft,helical pinion shaft, gear pinion shaft, forged pinion shaft with shaft pinion gearboth mounted to the shaft and as a part of the shaft, and other more kinds of forged shafts.

Feature of Pinion Shaft

lMaterial: stainless steel, carbon steel, alloy steel and as your requests

lStandard: ANSI, API, ASTM, BSI, DIN, GB, ISO, JIS and more standards.

lMechanical Properties: customized requirements are accepted.

lHardness: customized requirements are accepted.

lSurface treatment: rust preventive oil and according to your requirements.

lApplication: mainly used in various machinery equipment in the fields of mining, metallurgical, chemical industry, construction, and so on.

lQA and DOC: chemical composition report, mechanical properties report, UT report, PT report, heat treatment report, dimensions check report, hardness report and more

lWe can offer third-party inspection.

lProcess: raw material purchasing - forging - rough machining(rough hobbing) - heat treatment - semi machining (semi-final hobbing) - hardening of tooth surfaces - finish machining(gear grinding) - painting and packing.

lVarious process conditions are available.

lCertificates: ISO 9001:2015

lProducts ability: Max module:45

lHeat treatment: quenching and tempering, normalizing and tempering.

lTooth surface treatment: carburizing and quenching, surface quenching.

lQC: fabrication schedule, fabrication process chart, inspection and test plan.

lPacking: coated with rust preventive oil, seaworthy packing.

Our Advantage of Pinion Shaft

lMore than 30-year experience

lSO9001:2015 Standard certified

lCustom-made design

lAll seamless forged

lStrict quality control

lPrompt delivery

Technical Parameter of Pinion Shaft

|

Name |

Pinion Shaft |

|

Material |

Forging carbon steel, forging alloy steel |

|

Diameter |

|

|

Length |

|

|

Module |

Part Performance of Pinion

|

Material |

OD/mm |

module |

application |

client |

|

30CrNiMo8 |

1201 |

39 |

Cement Rotary Kiln |

KHD |

|

30CrNiMo8 |

914 |

30 |

Cement Mill |

|

|

30CrNiMo8 |

1252 |

42 |

Cement Rotary Kiln |

|

|

30CrNiMo8 |

1252 |

42 |

Cement Rotary Kiln |

|

|

30CrNiMo8 |

1252 |

42 |

Cement Rotary Kiln |

|

|

30CrNiMo8 |

1201 |

39 |

Cement Rotary Kiln |

|

|

30CrNiMo8 |

1520 |

45 |

Cement Rotary Kiln |

|

|

30CrNiMo8 |

1092 |

42 |

Cement Rotary Kiln |

|

|

42CrMo |

420 |

20 |

Fertilizer granulator |

Malaysia |

|

42CrMo |

475 |

25 |

Fertilizer Dryer |

|

|

17CrNiMo6 |

683 |

/ |

Venezuela |

|

|

42CrMo |

550 |

25 |

Dryer |

Japan TSK |

|

45 |

420 |

20 |

Dryer |

|

|

17CrNiMo6 |

880 |

40 |

/ |

Venezuela |

|

ASTM 4340 |

828 |

36 |

/ |

Peru |

|

42CrMo4 |

700 |

25 |

/ |

Egypt |

|

42CrMo |

500 |

20 |

Fertilizer Dryer |

Malaysia |

|

41MoCr11 |

879 |

28 |

/ |

Romania |

|

17Cr2Ni2Mo |

745 |

Rotary Kiln |

Korea |

Send product request

Other supplier products

| Metallurgical Furnace | CIC main advantage in nonferrous metallurgical furnacelies in the manufacture of horizontal rotary furnace, Rotary refining furnace and bottom blow... | |

| Thrust Roller | CIC is a more than 30-year manufacturer and reputed supplier of thrust rollerused in rotary kilns, rotary type driers and so on. CIC has been speci... | |

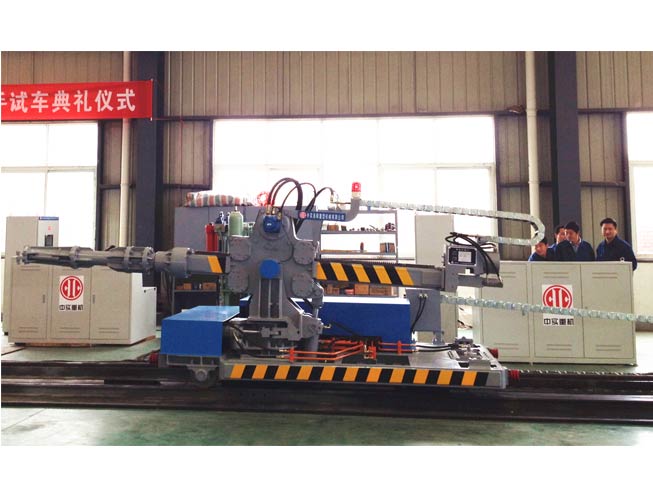

| Furnace Tapping Machine | We developed the discharge furnace robotic arm, based on the working process and tools of manual operation of slag port opening and closing of the ... | |

| Rotary Kiln | CIC’s equipment includes leading standardized heavy equipment and machinery products and related heavy machinery services, which can be sold ... | |

| CIC Mining And Cement Equipment | CIC's heavy equipment and machineryinclude not only market-leading standardized products, but also customized products and related services accordi... |

Same products

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | Seller: XIUCHENG RFID | Size:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transf... | |

| Micronized wax used for industrial paint processing | Seller: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | Seller: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... | |

| Fungicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... | |

| Fungicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... |