Introduction of Uncoiler and Its Functions and Features

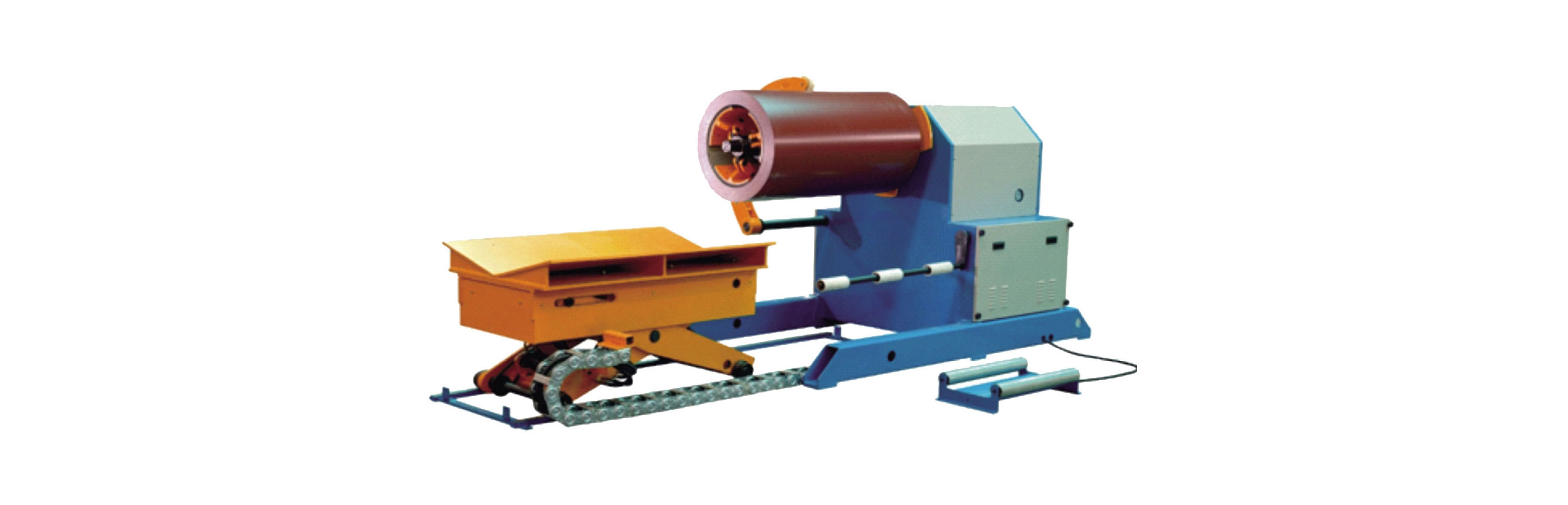

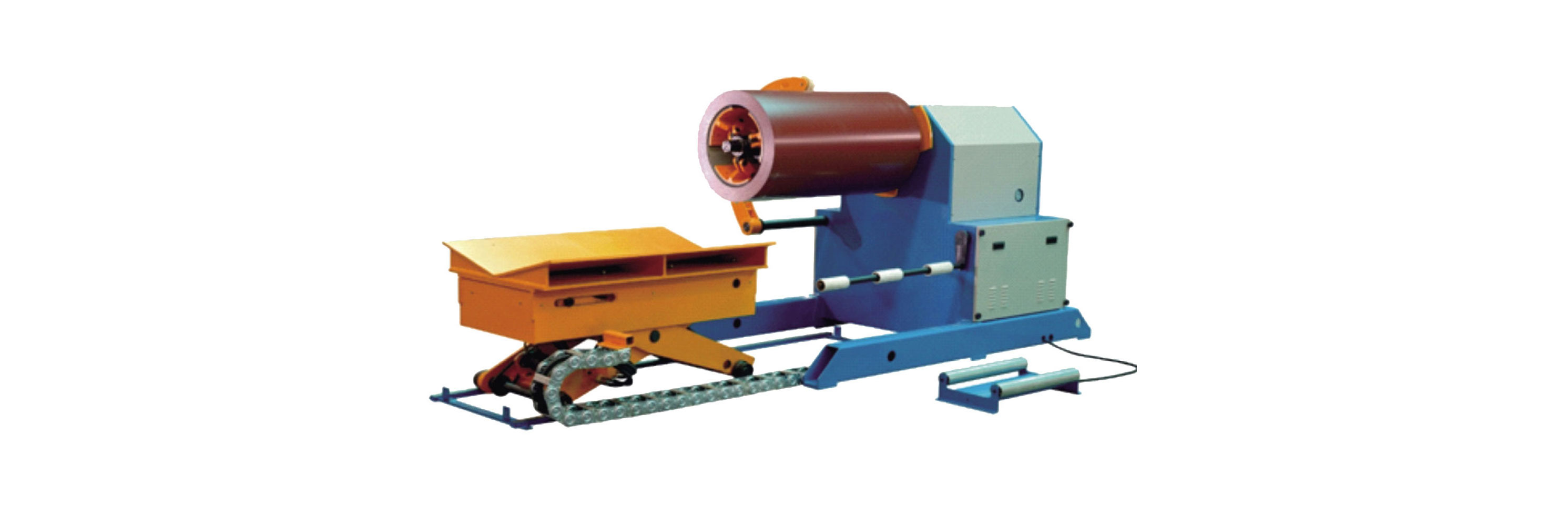

Uncoileris special equipment for sheet metal leveling. It is applied to the leveling line of steel plates and uneven plates, which can form uncoiling, leveling, shearing production lines, and other plate product production lines according to related configurations. The uncoiling machineis suitable for industries such as machinery, vehicles, metal products, household appliances, steel structures, and decoration.

Uncoiler machineis one of the essential equipment in the welded pipe production line. On the one hand, its function is to support the steel coil by tightening the inner hole of the steel coil; on the other hand, it is to feed the head of the steel strip into the leveling machine through the rotation with the cooperation of the straightening machine. Therefore, the performance of the uncoiling machine is very important to the entire production line. In many years of design practice, we have continuously optimized and improved the structure of the uncoiling machine, which has improved the performance of the uncoiling machine.

The main shaft of the uncoiling machine has two functions, namely, to drive the steel coil to rotate and to support tension of the steel coil. The realization of tightening is usually done by pushing the inclined slider by the oil cylinder or air cylinder installed with the main shaft. Small units use multiple cylinders, and large units use multiple cylinders; the realization of rotation is usually accomplished by the motor driving the main shaft to rotate through a reducer. The oil cylinder or air cylinder installed on the main shaft must rotate together with the main shaft, and the oil cylinder or air cylinder needs to be connected to one end of the working medium pipeline, and the other end of the pipeline is connected to the hydraulic station or solenoid valve.

One of the functions of the uncoiling machine of the unit is to unwind the strip under the tension after maintaining the strip. Another significant function is to realize the automatic centering of the strip under the central control (CPC). The conventional continuous rewinding and color coating unit is equipped with 2 uncoilers. Two uncoilers working alternately creates a prerequisite for the continuous production of the subsequent equipment of the unit.

The uncoiling machine is a welded box-shaped structure, and the variable frequency speed-regulating motor drives the drum shaft to provide the main power for the uncoiling machine after decelerating through the gearbox. The reel of the uncoiling machine is a hollow shaft, which is supported on the gearbox body through two bearings, and a transmission spur gear is installed between the bearings. The gearbox is lubricated by forced lubrication and is equipped with two constant speed motors for the closed-loop oil lubrication system. The mandrel is a cantilever structure, and its front end is supported by an external support bearing during unwinding to maintain the rigidity and stability of the uncoiling machine.

The mandrel of the uncoiling machine is connected to four sector-shaped plates through four sloped dovetail grooves on the end faces. Each sector-shaped plate is prevented from moving in the axial direction through a radial slide at the end but can expand and contract in the radial direction. A rotating oil cylinder is connected to the tail end of the reel shaft, and the piston rod of the oil cylinder drives the front-end quadrangular shaft to slide axially through a pull rod in the center of the reel shaft, thereby driving the sector plate to expand and contract radially. The nominal diameter of the reel can be increased by adding four fan-shaped plates. The frame of the steel uncoilercan be moved on the guide rail of the uncoiling machine base and driven by a hydraulic cylinder, which can realize the center position control. In order to strengthen the stability of the reel, a support arm device is designed on the head of the reel. When there is a steel coil on the reel, the support arm is driven by the cylinder to support the head of the reel, the support arm usually retracts, and it will not affect the coiling of the steel coil.

If you want to know more about jinggong,please contact us.

We also have roll forming machinefor sale, if you want to buy anything, contact us.

Send product request

Other supplier products

| H-Beam Straightening Machine | H-Beam StraighteningMachine is mainly used for the angle distortion straightening of heavy H-beam, it adopts hydraulic straightening which will hav... | |

| What Are the Advantages of Cold Roll Forming Machine? | What Are the Advantages of Cold Roll Forming Machine? The cold roll forming machineis composed of the hydraulic device of the cold roll equipment ... | |

| Pipe Bending Machine | The CNC Pipe Bending Machine is used to make a circle, curve, or spiral for workpieces. It is widely used in such fields as the petroleum industry,... | |

| Uncoiler | Our uncoiler machineis suitable for the uncoiling and conveying of thin metal sheets. It is the auxiliary equipment forChina roll forming machines.... | |

| C/Z Purlin Roll Forming Machine | The c purlin forming machinecan form hot/cold rolled metal strip through leveling, cold roll forming, punching and cutting off to produce C type or... |

Same products

| YC160W Wheel excavator YC160W | Seller: Guangxi Yuchai Equipment Technology Co., Ltd | YC160W Wheel excavator YC160W wheel excavator is a new generation of full hydraulic wheel excavat... | |

| Yuchai U20 mini excavator | Seller: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai U20 mini excavator Improvements in Over 80 Details: Tailless Excavator U20 is a Yuchai ... | |

| Yuchai YC80 small excavator | Seller: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai YC80 small excavator International brand engine It is equipped with Yanmar 4TNV98C natur... | |

| Top Type Hydraulic Breaker | Seller: Guangxi Yuchai Equipment Technology Co., Ltd | Top Type Hydraulic Breaker With the higher restriction of blasting control,hydraulic breakeris w... | |

| S35-Electric Skid Steer Loader | Seller: Guangxi Yuchai Equipment Technology Co., Ltd | S35-Electric Skid Steer Loader Yuchai S35 Electric Skid Steer Loaderis compact and flexible, des... |