PU/PIR Continuous Sandwich Panel Production Line

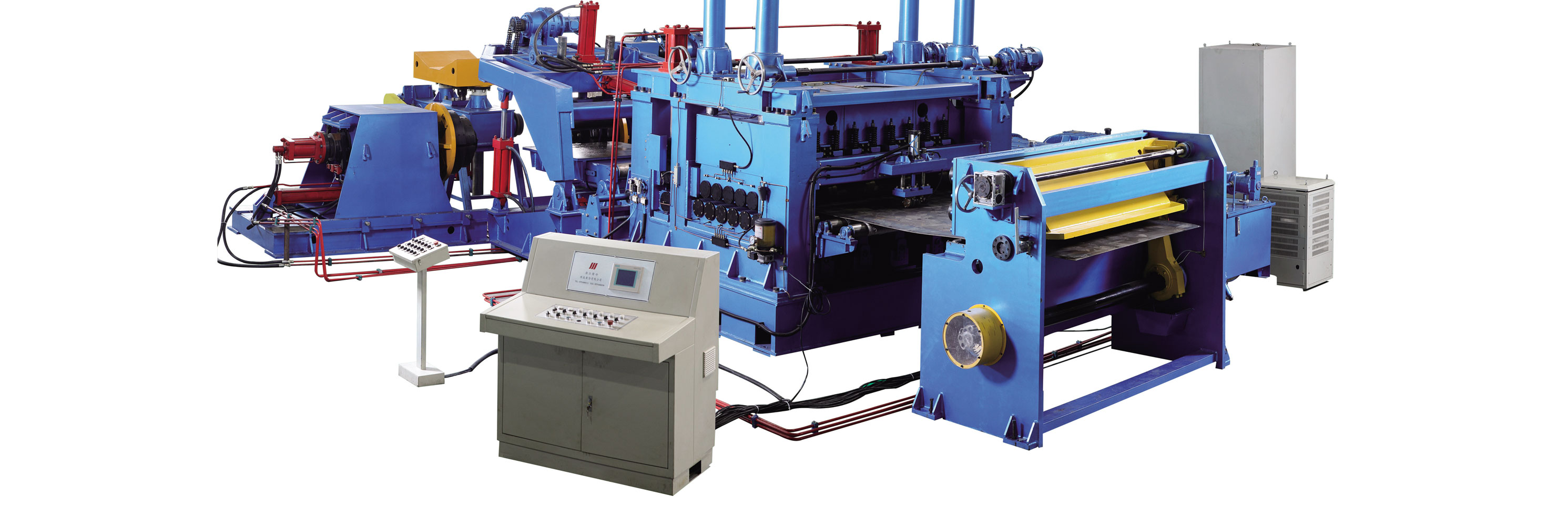

Continuous pu sandwich panel line, is an automatic production line, which is consisting of decoiler, film coating, pre-cutting, cutting equipment, roll forming system, preheating, foaming, solidification, band saw cutting, cooling, stacking and packing. The whole PU/PIR sandwich panel production line integrates technologies of mechanics, chemistry, electrical control, hydraulic pressure pneumatic and temperature control.

Jinggongis one of the leading sandwich panels manufacturersin China who has been specialized in providing high-quality polyurethane sandwich panelproduction line. The continuous pu sandwich panel linewere exported to many countries, such as Poland, Brazil, Jordan, Kuwait, Saudi Arabia, Tunisia, and so on. The production line performance has got unanimous approval and favorable comment from domestic and international customers. Feel free to contact us for pu sandwich panel production line price!

Video Of PU/PIR Continuous Sandwich Panel Production Machine

Zhejiang Jinggong Science and Technology Co., Ltd., which is located in Shaoxing, Zhejiang, developed the pu sandwich panel machineby themselves. This line has reached the world's advanced technology, stopped relying on import, and entered the time that there is no PU production line manufacturer in China. It means China localization age of PU production line is coming. The PU production line made by Jinggong consists of decoiler, roll forming machine, preheating, high pressure foaming, double belt machine, bandsaw, stacking, packing and cooling, realizing an automatic production from uncoiling to packing. Max production speed is 12 meters per minute. Annual output is 1 million square meters.

Features of PU/PIR Sandwich Production Line

Beautiful and applicable, multiple functions, such as thermal isolation, sound isolation and flame retardance.

Using heated air recycle oven, strictly control the temperature of PU foaming and solidification in suitable range.

Using high-pressure foaming system, precise measurement, high stability, little dust in the locale, protect the worker's health.

Using 141B or Pentane as foaming agent. Instead of carbon chloral-fluoride, make the PU foaming treatment become an environmental production craft.

Special double belt conveyor, flat surface of sandwich panel, even thickness, anti-pattern

Operation system controlled by PLC computer, personal design and simple operation.

Panel Drawings Of PU/PIR Continuous Sandwich Panel Production Line

Send product request

Other supplier products

| Cut To Length Line | Thischina cut to length machineis special equipment for uncoiling, leveling, cutting and stacking the steel sheet according to the requirement of t... | |

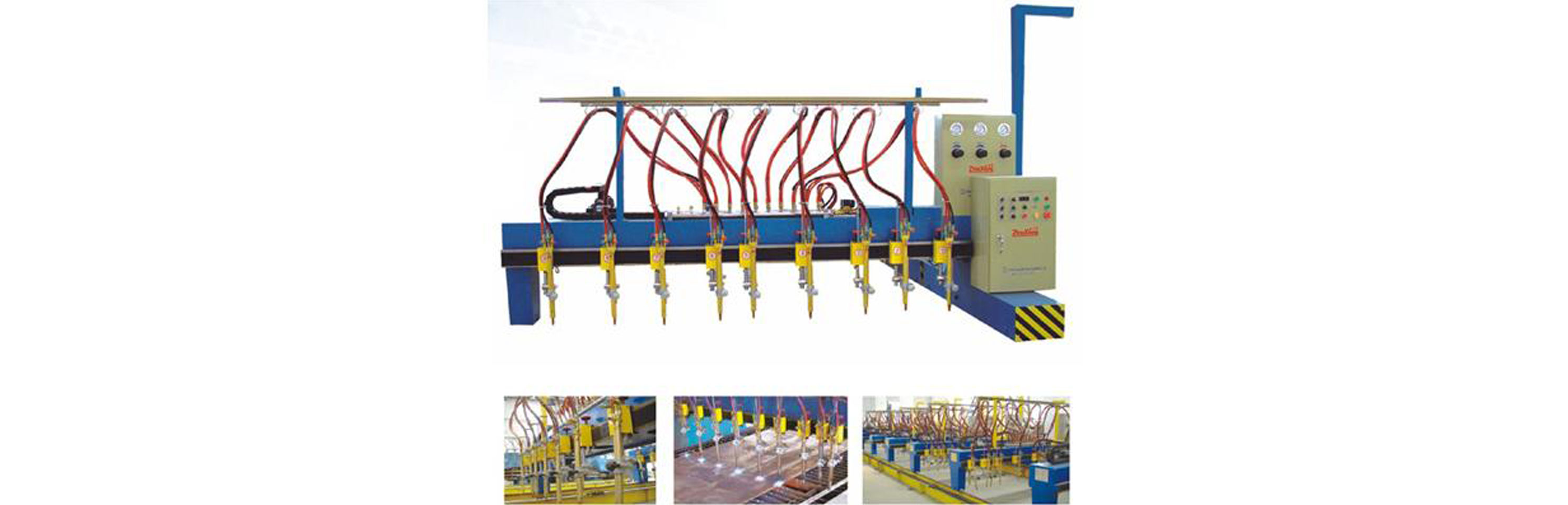

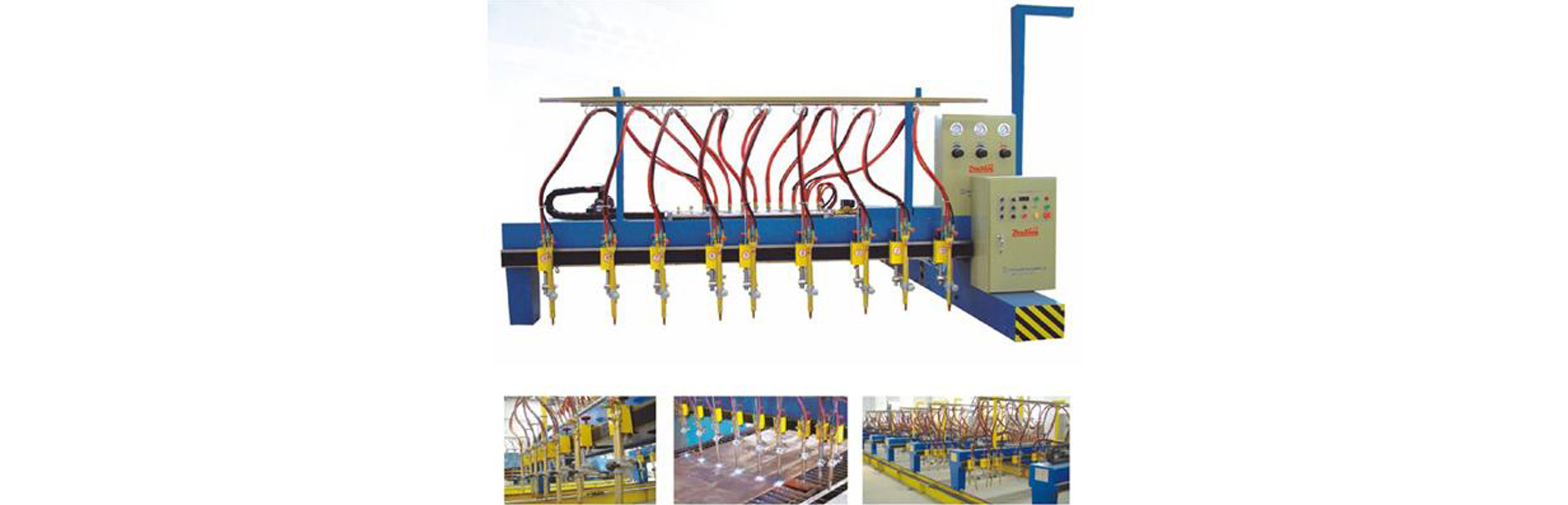

| CNC Flame Cutting Machine | The cnc flame cutting machineis a multifunctional thermal auto-cutting device combined microcomputer controlling, precise machinery and oxygen-acet... | |

| CNC Flame Cutting Machine | The flame cutting machineis a multifunctional thermal auto-cutting device combined microcomputer controlling, precise machinery and oxygen-acetylen... | |

| Downspout Roll Forming Machine | This downspout roll forming machinecan produce the sealed color water pipes by forming the colored steel sheet and whipstitch it. Thedownspout form... | |

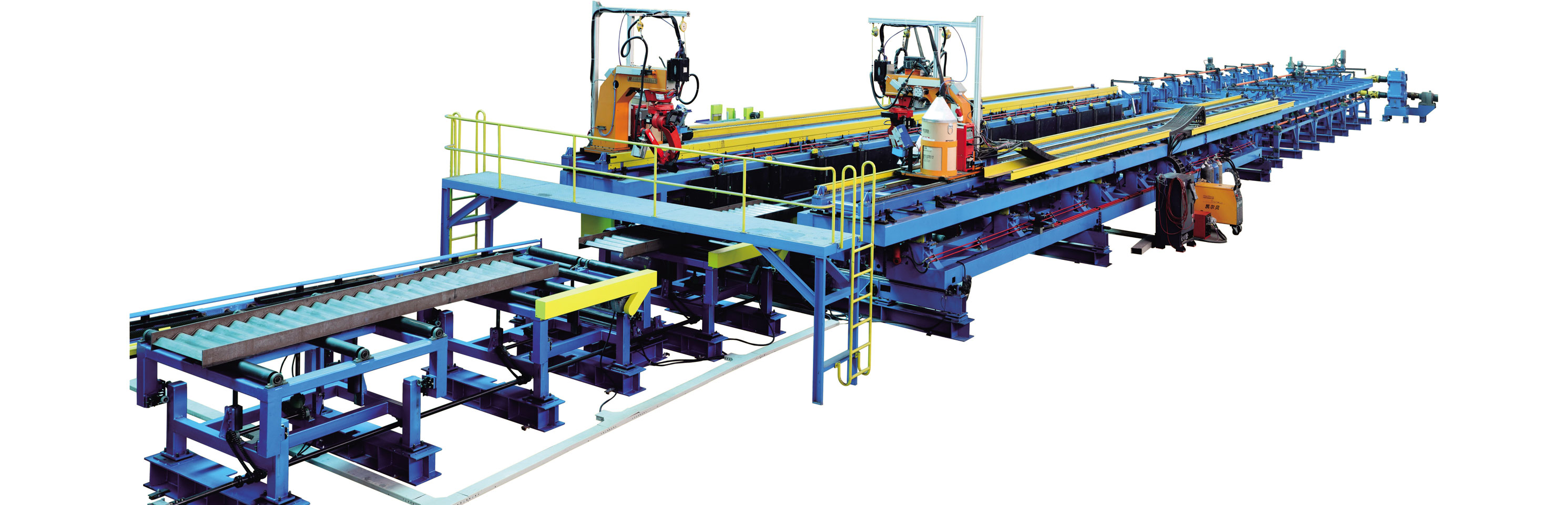

| Corrugated Web H-beam Welding Line | The corrugated web beamautomatic welding machine adopts the welding robot originally from Italy which automatically controls the works such as the ... |

Same products

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | Seller: XIUCHENG RFID | Size:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transf... | |

| Micronized wax used for industrial paint processing | Seller: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | Seller: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... | |

| Fungicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... | |

| Fungicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... |