Medical Silicone Rubber Injection Molding

With more than 20 years of experience in injection molding, as the medical silicone molding companyin China, we specialize in various molding process techniques including medical device plastic injection molding and medical silicone injection moldinglike LSR and solid rubber to make the highest-quality product. Packson provides custom medical grade silicone injection molding from small to large quantities. We are also able to add additives like colorants if customers need this customized medical device molding service. With strict tolerances, we specialize in making medical grade silicone injection molding parts like catheters and masks. To meet customer's demands, we built a Class 8 medial injection moulding cleanroomfor Liquid Silicone Rubber Molding with 12 injection presses. As an clean room injection manufacturerfor BD and with 7&24 service, Packson delivers 200k-300k pcs LSR parts every week to the USA. With the rapid development between BD and Packson, we decide to expand the cleanroom of LSR molding for new cooperation. Please don't hesitate to contact us if you need medical grade silicone injection molding parts. Get you personal solution now!

Medial Injection Moulding Cleanroom Capabilities

Normally we build the medial injection moulding cleanroom is for producing medical devices with strict requirements of cleanness. We also enable combine product by all kinds of materials which help us to precisely meet customer demands.

Our cutting-edge equipment, fully skilled engineers, and advanced technology have turned to help decrease project missing and save more time and cost which convert into great efficiency.

As the medical silicone moldingcompany, Packson makes medical devices and assembly of devices at clean room injection molding for meeting the demands of customers from the medical industry. The medical devices are molded by a variety of materials including medical grade thermoplastics for all kinds of healthcare and medical standard approvals. We keep focusing on creating medical components from small batch to high production quantities through ISO Class 8 cleanroom environments. In order to provide a full spectrum of OEMs medical device injection molding service for customers, we have the capability of offering value-added services like ultrasonic welding, printing, assembling, packaging, and sterilization.

Here are more value-added services about medical device injection molding:

Part concept design

Design confirmation and implementation

Design assessment and review (DFM/mold flow analysis, tolerance analysis, feasibility studies)

Prototype molds making for proving concept/design

Medical Device Injection Molding Processing

Tool Modification and maintenance

Medical device injection molding confirmation

Injection molding

Contract manufacturing services

Contract packaging services

Process for Medical Grade Silicone Injection Molding

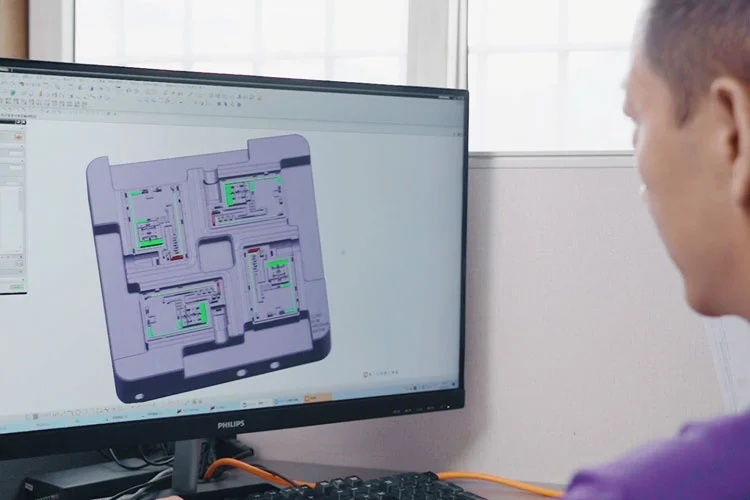

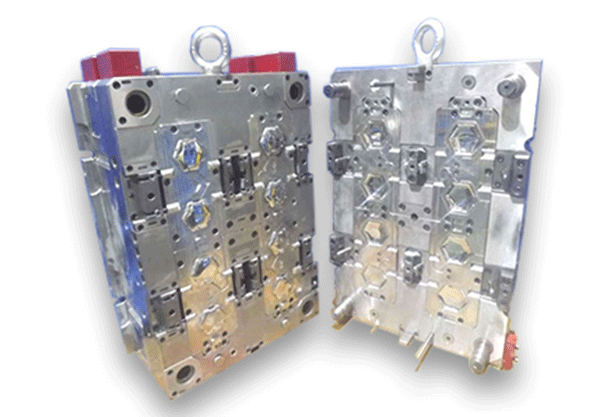

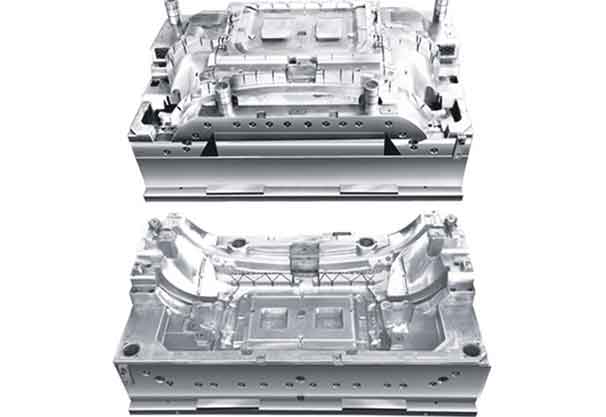

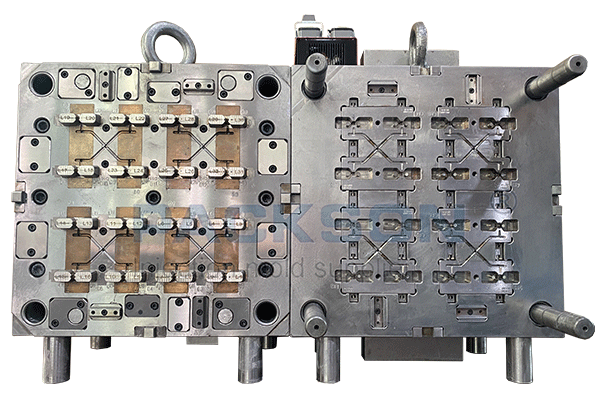

Our medical device injection molding parts are made by injection mold. The first step for making mold is to review the part design. Our medical device injection molding normally can reach 100,000 cycles even more if we use suitable steel material for the mold. Packson offers medical device molding service of a lifetime warranty for molds by mold maintaining. Here we have a professional engineering team that is dedicated to your injection molding production.

Process for Injection Molding Production:

Quick response for mold and part quote

Analyzing part design and make a personal solution

Create a professional team of project management

Ordering steel material and start mold processing

Weekly schedule for mold processing

Mold Trial and make samples production

Samples checking and make mold modification

Finish final version samples and mold shipment

As one of the most professional medical plastic injection molding companies, Packson Moldprovides custom molding services, lsr injection molding, medical silicone overmold injeand etc. We have amassed considerable experience and understanding of the practical possibilities in this field. Contact us to know more.

Send product request

Other supplier products

| One-stop Injection Molding Service Expert | For more than 15 years, Packson Mold has become an excellent manufacturer that is enabled to make parts with high tonnage and large size thanks to ... | |

| One-stop Injection Molding Service Expert | ISO Class 8 Clean Room Quality Control Low & High Volume Manufacturing Competitive Price Reliability and Stability For more th... | |

| Precision Injection Molding | Precision injection molding is a process that requires high technique and the use of precision molds and precision machines. The process of precisi... | |

| Prototype Injection Mould | Prototype molds are rapid processing for the molds. It's totally different from production molds as they can't be used in the long term. As a profe... | |

| Multi-cavities Injection Molding | Multi cavity mould is an injection mold that has more than one cavity. The shape of each cavity is the same. Multi cavity mold design is to produce... |

Same products

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | Seller: XIUCHENG RFID | Size:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transf... | |

| Micronized wax used for industrial paint processing | Seller: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | Seller: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... | |

| Fungicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... | |

| Fungicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... |