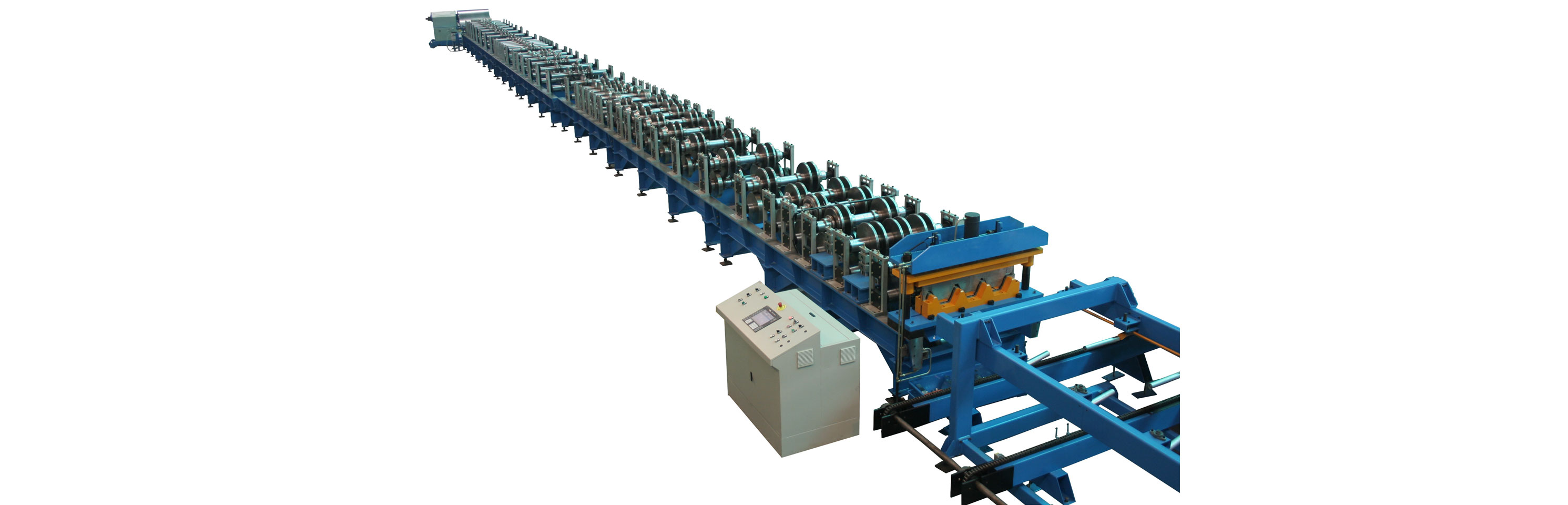

Steel Deck Roll Forming Machine

The sheet produced by this steel roll forming machine has high strength with big wavelength, and adheres well to concrete. Used on tall buildings, it not only saves steel mold sheet, but also reduces the weight of the storey.

The common thickness for final products depends on different material, normally it's 0.6-1.2mm. For the recommend profiles, we can recommend the popular end products and we can also design deck roll former according to your drawings.

Working process of the deck roll former: Decoiling → Guided feeding → Roll forming → Cutting to length → finished panel

HG series forming machine is professional equipment for steel decking. The steel deck features a simple design, high ribs, high strands, and specially used in high story building and the large or medium-size industry or civilian construction. It helps users to simplify the construction process and save investment. The equipment has stable performance and lower power consumption, which gains customers phrases.

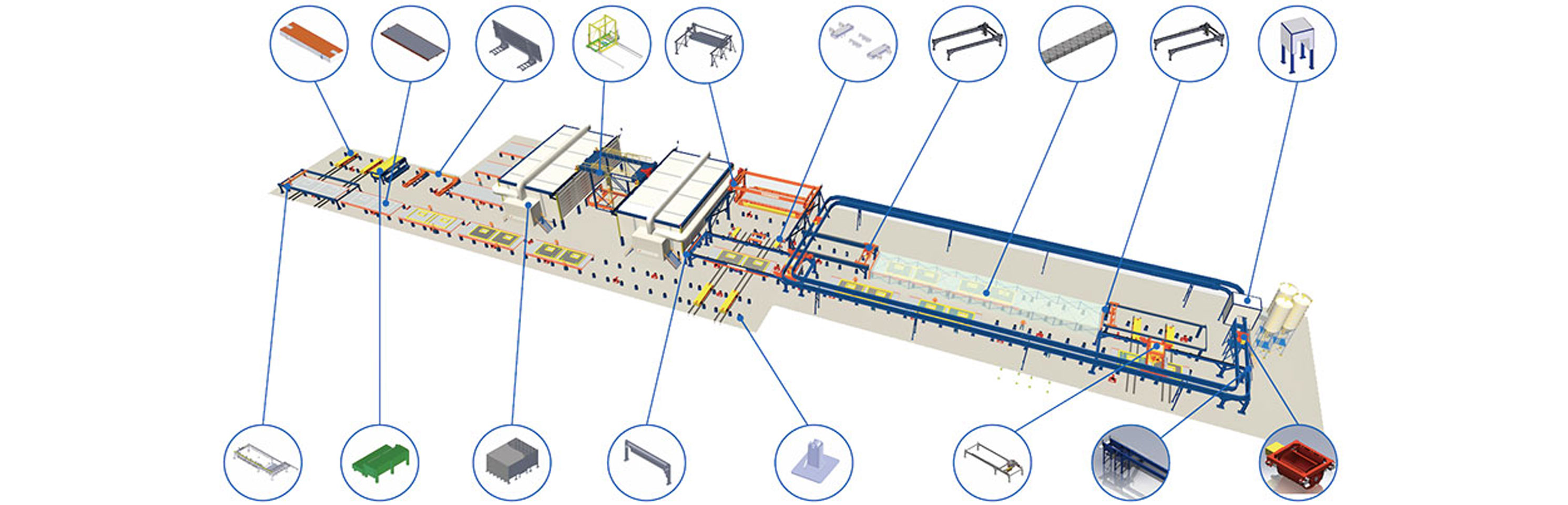

The self-supported steel deck wholesale production line, self-developed by Zhejiang JinggongScience and Technology Co., Ltd., specially developed for speeding up construction, reducing the workload on spot, and saving construction cost. It is widely applied to medium and high-story steel structural construction that can save moulding for structure and to decrease the load of floor. The production metal deck roll forming lineis featured by reasonable structure, good appearance, high quality, etc. It consists of truss welding line, floor deck roll forming machine, and board spot welding machine, combining mechanism, electricity, hydraulic, and pneumatics with microcomputer control. It performs whole set production process of steel molding board’s truss, galvanized steel forming and assembling & welding. The line's annual single-round production capacity reaches 300 000 square meters

Technical Parameters Of Steel Deck Roll Forming Machine

|

Item |

Para |

Memo |

||

|

1 |

Suitable material |

Type |

galvanized steel, |

|

|

Thickness (mm) |

||||

|

Yield Strength (MPa) |

≤345 |

|||

|

Width (mm) |

1220 |

|||

|

2 |

Forming Speed (m/min) |

About 20 |

Not including cutting time |

|

|

3 |

Forming main motor power(KW) |

22 |

Depend on actual design |

|

|

4 |

Main hydraulic station power(KW) |

Depend on actual design |

||

|

5 |

Decoiler motor power (KW) |

Depend on actual design |

||

|

6 |

Decoiler hydraulic station power (KW) |

3 |

Depend on actual design |

|

|

7 |

Total power |

36 |

Depend on actual design |

|

|

8 |

Power |

AC480V,60Hz,3 Phase |

||

Supply List Of Steel Deck Roll Forming Machine

|

Name |

Remark |

||

|

1 |

Decoiler |

1set |

|

|

2 |

Guiding device |

1set |

|

|

3 |

Forming system |

1set |

|

|

4 |

Cutting system |

1set |

|

|

5 |

Output device |

1set |

|

|

6 |

Hydraulic system |

1set |

|

|

7 |

Electrical system |

1set |

Main components ofSteel deck floor roll forming machine

The line consists of uncoiler, transmission, roll forming, post-shearing, auto stacker, hydraulic system, controlling system, and etc.

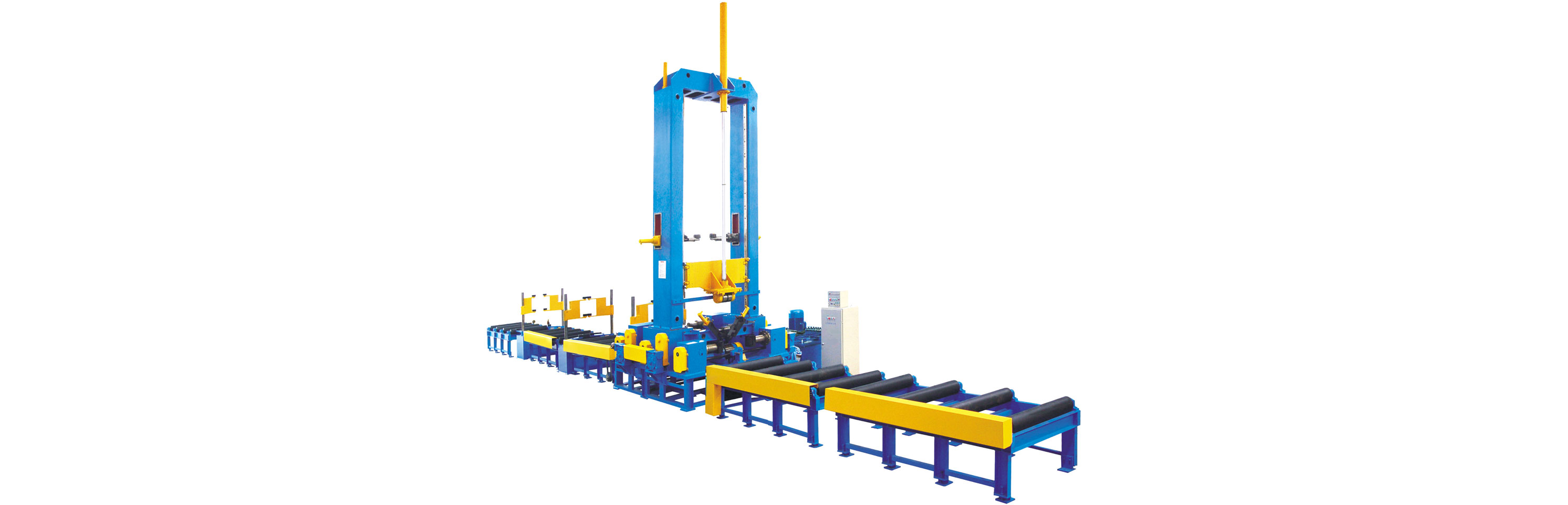

Uncoiler

Cantilever-type fully automatic uncoiler adopts ultrasonic sensor technology and frequency inverter adjustment. The pressing arm hydraulic-driven power is optional. All electrical parts and hydraulic parts are installed inside of uncoiler frame.

Roll Forming

The roll forming system consists of a guiding device, machine base, transmission parts, and roll forming rollers, etc. The cooling and lubricating device is optional.

Post-shearing device

The post-shearing device adopts frame-type hydraulic shearing. The panel is cut stably.

Auto staker

Programming control can calculate the quantities of shear panels. and automatically stacking, moving transversally or lengthways for packing.

Hydraulic system

Hydraulic system is installed inside the machine base. The design is reasonable and compact.

Controller

Mitsubishi PLC Frequency inverter adjustment to realize fully automatic operation.

Operator

The operator can set parameters such as badges, length of panel's quantities in the touch screen

With 53 years' experience, Jinggongis specialized in manufacturing high-qualityroll forming machine for sale, feel free to contact!

Send product request

Other supplier products

| Precast Concrete Panel Production Line | As the main component in precast concrete components, the assembly part, connection, combination of cast-in-place reinforced Concrete structure, PC... | |

| Characteristics of Rockwool Sandwich Panel Machine | The rockwool sandwichpanel machine and its production process realize that the rockwool and steel plate can be combined into a whole through automa... | |

| H Beam Shot Blasting Machine | Hbeam shot blasting machineis designed and manufactured to clean the surface of the section steel. It is ideally suited for removing the rust, scal... | |

| CNC Flame Cutting Machine | The flame cutting machine for saleis a multifunctional thermal auto-cutting device combined microcomputer controlling, precise machinery and oxygen... | |

| H-Beam Assembling Machine | The clamping and alignment of the web plate and flange plate will be done in H-beam assembly machine, there also have automatic tack-welding. Jingg... |

Same products

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | Seller: XIUCHENG RFID | Size:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transf... | |

| Micronized wax used for industrial paint processing | Seller: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | Seller: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... | |

| Fungicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... | |

| Fungicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... |