Bending Parts

The bending process is one of the common processing stamping methods, it refers to the forming method that a sheet and coil is bent into various shape and angle of parts.

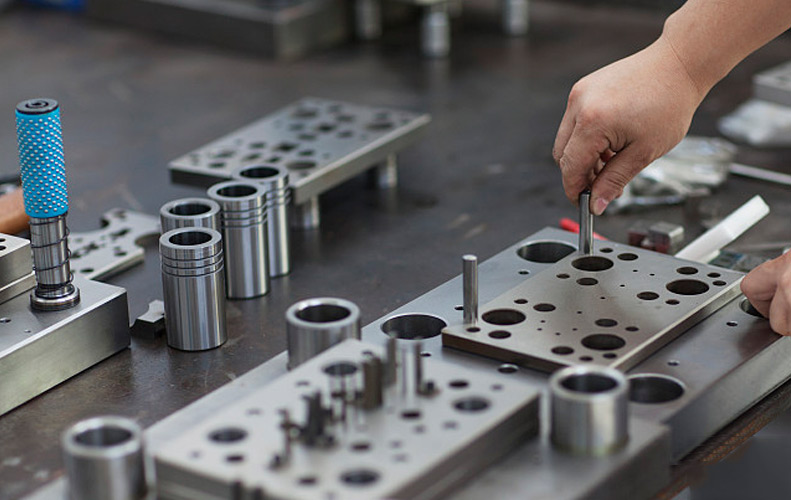

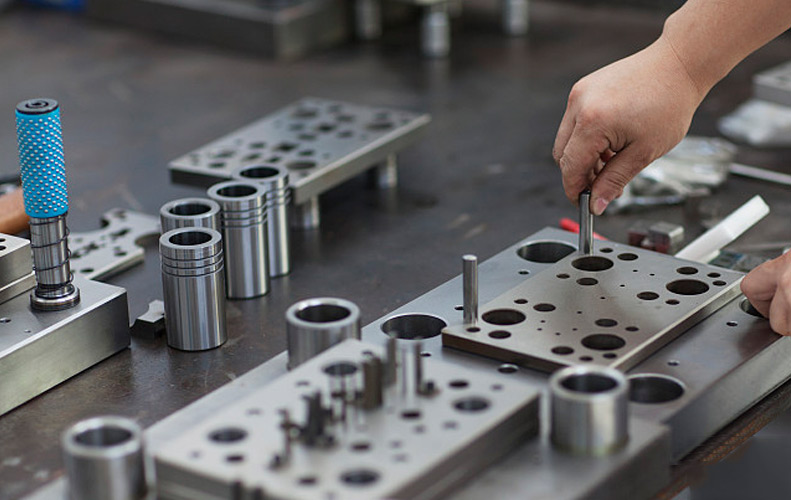

Orienson's Bending Parts

The structured shape, size, precision, materials, and technical requirements of bending parts must be conformed to the requirements of the bending process. Various shapes such as the U-shaped bending and V-shaped bending, cap-shaped parts, arc-shaped parts, etc can be made through the bending process. Orienson can provide solutions with a reasonable process, high precision, and low manufacturing cost according to customer requirements, we always commit to reducing the production cost, improving quality, and improving product yield, welcome your consultation.

Bending PartsDesign

For the shape of simple bending stamping parts, such as V-shaped, U-shaped, L-shaped, Z-shaped, etc., we can adopt bending once-forming. For metal bending partswith complex shapes, it is generally necessary to adopt multiple bending forming.

As deformation will affect the shape accuracy of multi-angle bending parts, we generally bend the outer angle first and then bend the inner angle. The first bending should be set aside some reliable positioning for the next bending to ensure the first bending shape would be not destroyed by the next bending.

The work blank of metal bendingparts with asymmetric structure is prone to deviation during the bending process, we should try to adopt the technique by curving in pairs and then cutting apart.

Bending times and working arrangements of bending parts must be considered comprehensively according to the complexity of workpiece shape, material performance, precision requirements, and the size of the production batch. Reasonable bending process can reduce bending times, simplify die structure, improve workpiece quality and productivity.

Application Of Bending Parts

Bending is the most common processing method in the stamping industry. Its metal stamping parts are widely used in the automobile industry, electronic and electrical industry, communication fiber industry, the energy development industry, and so on. Orienson has 20 years of industry experience in stamping, adhering to the manufacturing spirit of stamping craftsmen, In strict accordance with TS16949 standards to develop new product development, quality control, lean production management, and TPM management related production management process. We commit to meeting our customers' requirements with the best quality, welcome customers who need stamping parts to consult more details.

What is the Common Defects and Technological Countermeasures of Bending Parts

Bending is a common process in stamping parts. In view of bending defects, Orienson adopts corresponding effective process measures through process control and prevention to improve the quality of the workpiece.

- The bending crack, the crack is one of the most common problems of stamping bending part.

As a professional metal bending factory, we provide metal stampings, metalwork and stamping, deep draw metal stamping, sheet metal bend radius, custom cnc machiningand etc. Want to know metal bending priceor more, contact us.

Send product request

Other supplier products

| Steel Stamping | Steel stampingmaterials are mainly hot rolling and cold rolling steel plates and steel bands. Orienson's Steel Stamping Steel stamping material... | |

| Fine Blanking Parts | Fine blanking is short for precision blanking. Orienson's Fine Blanking Parts Fine blanking is a kind of precision stamping processing technology... | |

| Electrical And Electronic Accessory Metal Stamping | Orienson has been trusted by the top international brands for our high-quality standard and innovative solutions, and have expanded to cover Low vo... | |

| Copper Stamping | Copper stampingis the processing of copper metal materials into custom-shaped hardware through stamping die. Orienson's Copper Stamping Copper is ... | |

| Stainless Steel Stamping | Stainless steel stampingis the process of stainless steel material processed by using the mold, which makes its deformation or fracture has a certa... |

Same products

| Wedge Wire Screw Press Screen for Manure Separator | Seller: Apoaqua | Wedge wire screw press filter screen is mainly used in the application of dewatering manure in fa... | |

| gardening cultivating tools | Seller: Dongyang Guorui Industry And Trade Co., Ltd. | Our gardening cultivating tools are the epitome of quality and functionality, desig... | |

| Kingwood Wood Pellet | Seller: Jiangsu Kingwood Industrial Co., Ltd. | Our Wood Pellets are produced through a meticulous process that involves compressin... | |

| 2BV2 070 Water Ring Vacuum Pump for Mine | Seller: Greentech International (Zhangqiu) Co., Ltd | 2BV2 070 Water Ring Vacuum Pump for Mine2BV series liquidring vacuum pumps are suitable for pumpi... | |

| 2sk-30 Liquid Ring Vacuum Pump/Motor Not Included | Seller: Greentech International (Zhangqiu) Co., Ltd | Greentech International (Zhangqiu) Co., Ltd is the professional liquid ring vacuum pump supplier.... |