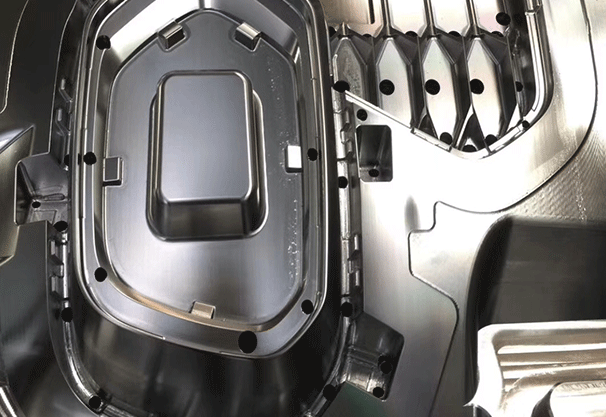

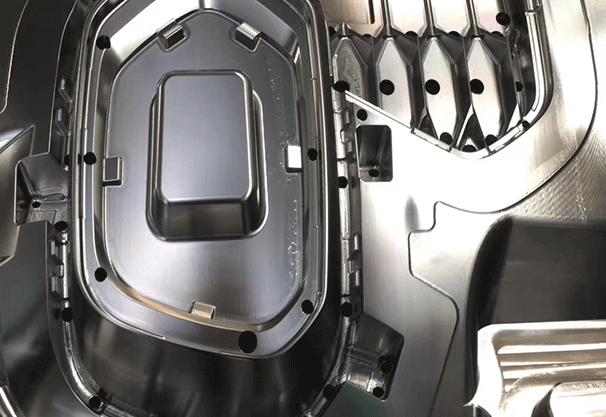

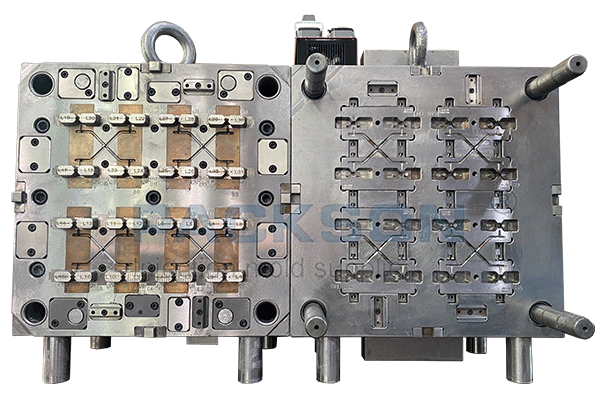

Mold Components

We provide custom made plastic parts-Sliders, inserts, lifters, blocks, ejector pins, and other mold components for our worldwide clients in 3 days via DHL or TNT. We are able to manufacture custom made plastic parts(Mold slider, lifters, Mold inserts, Core and cavity, blocks, ejector pins) with high precision. With more than 10 years of experience working with European and American customers, we are familiar with different various standards and processes. Full support you to assemble components in your house.

Packson Custom Molded Parts Capabilities

Machining Process: CNC Milling, CNC Turning, CNC Drilling, CNC Wire-cut, EDM , Grinding

Tolerance: ± 0.0002 in, ±0.005 mm

Leadtime: 3 days at the soonest

The Amount of Machines: 30 sets machines

Machinery Axis: 3-Axis,4-Axis,5-Axis

Industry Standard: ASNI, ASME, ASTM, ISO, Mil-Spec, RoHS

Available Materials For Metal Sheet

Type Alloy (parts) Features and characteristics Application (Industry)

Aluminum 6061 Upgrade corrosion resistance on 7075

Camera lens mounts,Electronic hardware, Couplings,Marines fittings,Prototypes, Aircraft fittings and Hardware

6061 - T6 All-purpose aluminium with medium strength.

Good forming ability, weld ability

It's made of magnesium and silicone.

7075 Greater strength than aluminum 6061.

Fuse parts,Worm gears,Keys,Regulating valve parts,Aerospace and defense applications;Bike frames,Aircraft, Meter shafts and gears, Gears and shafts, Missile parts,

Strong resistance to fatigue.

Copper C101 Electro copper without oxygen Automotive, General engineering,Domestic appliances,Electrical contacts,

High electrically conductive

Good corrosiveness in most environments

Low against acids, halogenic sulfides and ammoniacal solutions.

Steel 1018 Low carbon standard steel Rivets and parts in need of heavy welding

Great forming ability and welding ability

Case harden only

12L14 Great machinability Endless commercial products; probably more pounds used in turned products than any other bar stock

Case harden only

1137 Higher carbon, higher strength Higher stress applications, gears, shafts, studs

Direct hardening

Stainless Steel 304 The most widedly used stainless steel Household and industrial applications: screws, machinery parts, car headers, food-handling equipment,

Low carbon

Better welding ability and forming ability

316 Improved corrosion and chemical resistance than 304 Aerospace,Medical implants and surgical instruments,

Improved resistance to cracking and pitting

416 Free machining Applications that need less corrosion resistance, more hardness, or lower cost

Less corosion resistant than 300 series

Can be heat treated

17-4 PH Higher magnetism than 304 and 316 stainless steel Medical, aerospace, applications needing corrosion resistance and hardness

Oxidation and corrosion resistance

Why Choose Packson For Injection Mold Components?

Saving the cost of time

You may search multiple providers to complete the same project together. For instance, nominating A company to design tooling, B company to manufacture mold base, C company to manufacture inserts, sliders, lifters, and other components. Meanwhile, asking every supplier to check and verify the tolerance within your needs, so it's easy to assemble. After your company received all of the parts, you are able to assemble molds and trial molds. Comparing the normal procedure, it helps clients to save 20%-50% time on completing the whole project in this way.

Saving the cost of manufacture

The high cost of labor and process may make your headache. Especially in precise mould part manufacturer. With the lower cost of labor and high precise machine, we are able to provide injection mold components with 100% match in your requirement for you at a more competitive price. To make better profits and competitive power for you.

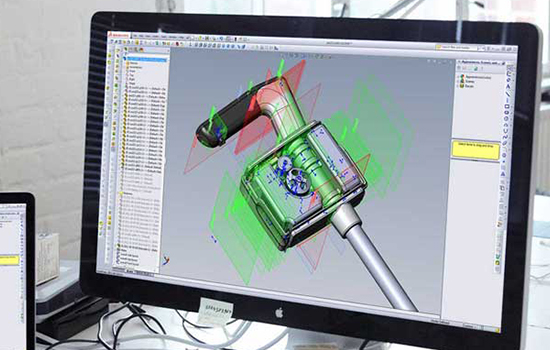

Quality control

Our workshop is equipping with various precise machines. Such as Taiwan high-speed CNC machines, GF wire-cut & EDM, CMM. After every process, the quality team will check the result of steel whether matches to 3D data or not. Meanwhile, before shipments, all of the parts need to be made a full inspection. And all of the reports will be passed by clients. In this way, it helps our clients to save the cost to prevent the trial molds repeatedly.

As aprofessional plastic moulding parts manufacturer, Packson Mold provides injection molding in china, custom molding services, rubber moulded components, insert molded parts,lsr injection moldingand etc. Want to know more, contact us.

There are many injection molded plastic parts manufacturers , but we are one of the best choices for you.

Send product request

Other supplier products

| Silicone Rubber Injection Molding | Silicone rubber injection molding has more than a half-century history since the late 1970s. There are two molding ways of silicone rubber injectio... | |

| Mold Components | We provide custom made plastic parts-Sliders, inserts, lifters, blocks, ejector pins, and other mold components for our worldwide clients in 3 days... | |

| Product Design & Development | In addition to providing moulding die designsolutions, we can also provide customers with product design optimization solutions to save more cost a... | |

| Multi-cavities Injection Molding | Multi cavity mouldis an injection mold that has more than one cavity. The shape of each cavity is the same. Multi cavity mold designis to produce m... | |

| Custom Contract Molding | Plastic Injection Molds for Sale ISO Class 8 Clean Room Quality Control Low & High Volume Manufacturing Competitive Price Reliability ... |

Same products

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | Seller: XIUCHENG RFID | Size:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transf... | |

| Micronized wax used for industrial paint processing | Seller: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | Seller: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... | |

| Fungicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... | |

| Fungicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... |