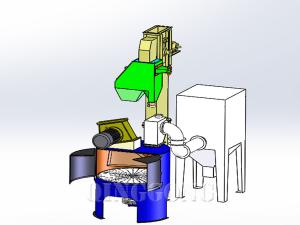

BARREL TYPE SHOT BLASTING MACHINE

The barrel surface blasting machineline provides outstanding performance and reliability. Designed for foundry, forge and heat treat requirements.

The Barrel Blast Machine or drum type shot blasting machineis the ideal solution to clean small to medium size parts that would normally become jammed in traditional Tumblast machine.

The Barrel Machine is the ideal solution to clean parts that would normally become pinched or jammed in our traditional Tumblast machine, reducing chances of part damage. Barrel machines are designed for easy maintenance to provide shorter downtime.

Features:

Efficient and uniform blast cleaning effect

Thin and small special parts can also be processed

Simple and accurate input and discharge

Simple maintenance

Advantage

Using magnetic separator

Since the treatment is a casting, there is lots of sand on the surface of the workpiece. The wind separator alone is not enough to separate the molding sand ; the magnetic separation roller make the rate of the sand separator more than 98%.

The advanced secondary dust removal mode, including the first-stage cyclone dust collector and the secondary cartridge filters dust collector, can effectively make the dust emission concentration far below the standard to reach ≤50 mg/m3;

Advanced nature of electrical control

Centralized control with Siemens touch screen and PLC.

Applications

Automotive

Iron, steel and metal foundries

Heat treat operations

Forging operations

Small stamping parts manufacturers

If you want to know more types of roto shot, please visit our website.

We also have kinds of roller shot blasting machinefor sale, anything you need, please contact us.

Send product request

Other supplier products

| CNC TURRET PUNCH PRESS | CNC punching machine is the machine that performs the punching, the operation that serves to make holes and cuts in the metal sheet. The CNC punchi... | |

| TUMBLE BELT SHOT BLASTING MACHINE | Tumble belt shot blasting machineor crawler shot blasting machineis the most universal among all shot blasters as their design makes them suitable ... | |

| ROTARY TABLE SHOT BLASTING MACHINE | Rotary shot blastermachineor table type shot blasting machineis suitable for various shapes and dimensions, casts, forged parts, pressed parts, ste... | |

| GAS CYLINDER SHOT BLASTING MACHINE | Gas cylinder shot blasting machine is used to automatically clean the surface of the cylinders by blasting of the abrasive coming from the blast tu... | |

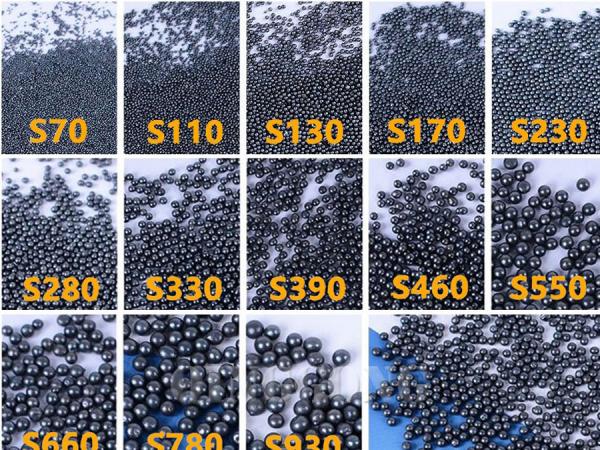

| ABRASIVE | QINGGONG MACHINERY can provide you with abrasive blasting service & supplies. Best abrasive for sandblasting Uniform particle size, good cleani... |

Same products

| Micronized polypropylene wax for injection moulding | Seller: Syntop chemical Co.,Ltd. | The incorporation of polypropylene micronized wax into injection moulding processes delivers the ... | |

| Drum Type Mobile Mixing Station | Seller: Yousheng Machinery Equipment Co.,Ltd | Drum Type Mobile Mixing Station Drum Type Mobile Mixing StationPortable Drum Concrete Batch Plan... | |

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | Seller: XIUCHENG RFID | Size:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transf... | |

| Micronized wax used for industrial paint processing | Seller: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | Seller: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... |