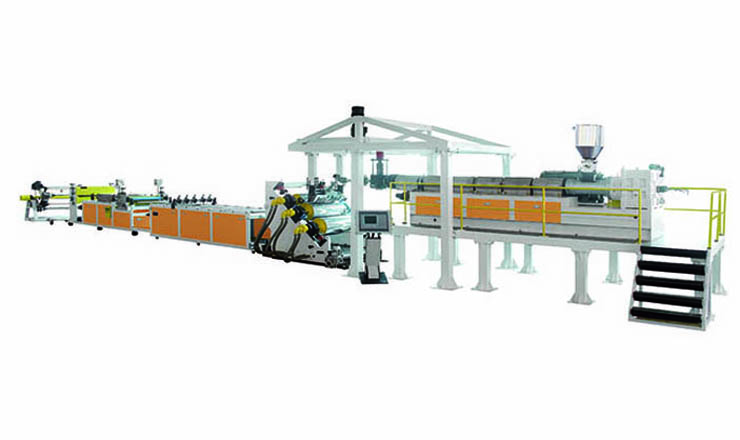

PP Sheet Extrusion Line

The pp sheet extrusion line chinaof Jinwei company is divided into:

PP, PS blister sheet, and stationery decorative sheet production line: PP and PS sheets are widely used, and can be directly used for the packaging of food and electronic products after Blister molding; Various transparent, two-color.

Frosted, 3D stationery piece. The multi-layer coextrusion production line can be customized according to customer requirements, and the output ranges from 100-1200kg / h.

PP, EVA, EVOH multilayer co-extrusion barrier sheet extrusion line.

Due to the increasingly stringent requirements of the market for products, Suzhou Jinwei has developed advanced five-layer symmetric and seven-layer asymmetric distribution technology, which makes the pp sheet extrusion produced by the equipment obtain better performance.

The composite high barrier fresh-keeping packaging sheet is mainly used in jelly packaging, food packaging such as high-grade meat food, fast food rice, medicine, cosmetics, and so on.

Description About PPSheet ExtrusionLine

|

Place of origin |

China |

|

Brand name |

Jwell |

|

Model number |

JW120 JW150 |

|

Certification |

CE ISO |

|

Minimum order quantity |

1 set |

|

Packaging details |

Wooden pallet packing |

|

Delivery time |

90days |

Specifications of PP Sheet Extrusion Line

|

Species |

Suction package sheet |

Stationery decoration sheet |

|

Raw material |

PP, PS, HIPS, EVOH |

PP, PS, PE |

|

Production thickness(mm) |

||

|

Products Width(mm) |

600-1500 |

600-1500 |

|

Output (kg/h) |

150-500kg/h |

100-450kg/h |

PP Sheet Extrusion Line Application

PP sheet produced by pp sheet extrusion and making machine not only has high transparency, good barrier, low density, non-toxic and hygienic but also can be recycled. It will not produce toxic and harmful gases during heating or combustion, will not endanger human health, and will not corrode equipment. It is a new type of green environmental protection packaging material. PP sheet of pp hollow sheet extrusion linechina can be made into various products through secondary processing such as thermoforming, which is mainly used for packaging of food, medicine, medical devices, and so on.

If processed into jelly boxes, dairy packaging boxes, fast food boxes, cold drink containers, trays, microwave oven appliances, etc., they can be used for food packaging; The processed blister can be used for the packaging of solid preparations such as drug tablets and capsules. In foreign countries, especially in developed countries and regions, transparent PP sheets are widely used in food packaging and other fields.

FAQ about PP Sheet Extrusion Line

Can multi-layer structured sheets be produced?+

Yes, due to the increasingly stringent requirements of the market for products, jwell extrusion machinery company has developed advanced five-layer symmetric and seven-layer asymmetric distribution technology, which makes the products produced by the equipment obtain better barrier performance and better distribution ratio.

How long is the delivery date?+

How long is the warranty period+

PP Sheet Extrusion Line Performance and Advantages

PP sheet is an environment-friendly material. The advanced five-layer symmetrical and seven-layer asymmetric distribution technology developed by JWELL Extrusion Machinery Co., Ltdmakes the products produced by the equipment obtain better barrier performance so that the products can be matched more flexibly and diversified, and the equipment cost is cheap and the operation is simple. You are welcome to consult and buy.

Send product request

Other supplier products

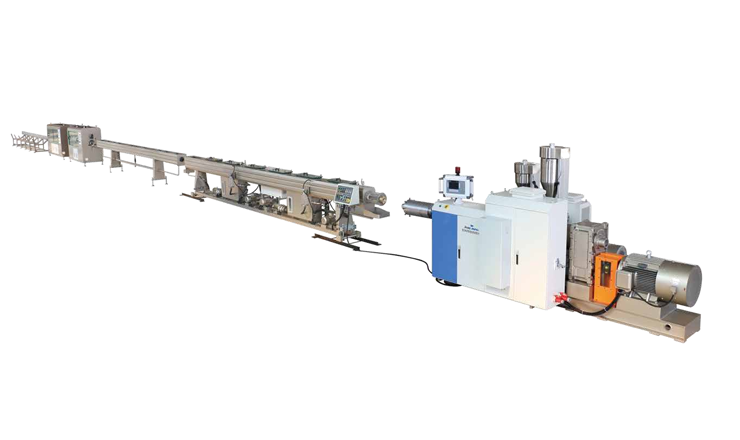

| Pipe Extrusion Machine | JWELL Machineryis designed and developed in a new idea, pipe and profile extrusionline produces PP pipe series, PVC pipeline series, ABS pipeline s... | |

| Pipe Extrusion Machine | JWELL Machinery Chinais designed and developed in a new idea, pipe and profile extrusionline produces PP pipe series, PVC pipeline series, ABS pipe... | |

| Plastic Profile Extrusion Line | This plastic profile extrusion lineconsists of Single Screw Extruder, Vacuum Calibration Table, Haul-off Unit, Cutter and Stacker, the producing li... | |

| PP Pipe Extrusion Machine | The series of PP pipe extrusionmachine lines mainly extruded production: MPP power pipe, PPR, Pert, PEX, cold & hot water pipe, RB, PO, MULTI-L... | |

| PS Sheet Extrusion Line | The PS sheet production line of JWELL company is divided into: GPPS plate production line: ordinary GPPS plate is mainly used for advertisin... |