PDC (Polycrystalline Diamond Compact) Cutter

As a superabrasive ltd, E-Grind produces high-quality Polycrystalline diamond composite(PDC) and polycrystalline diamond compact cutters.

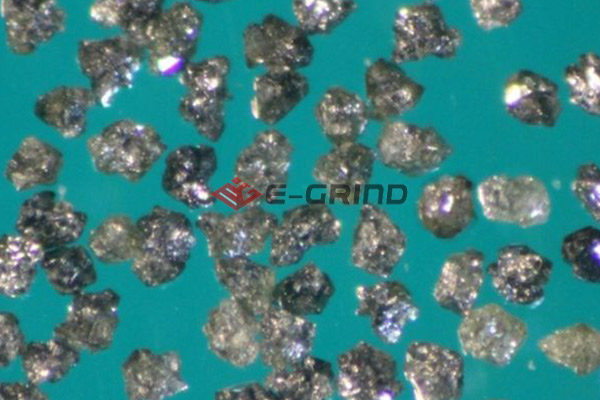

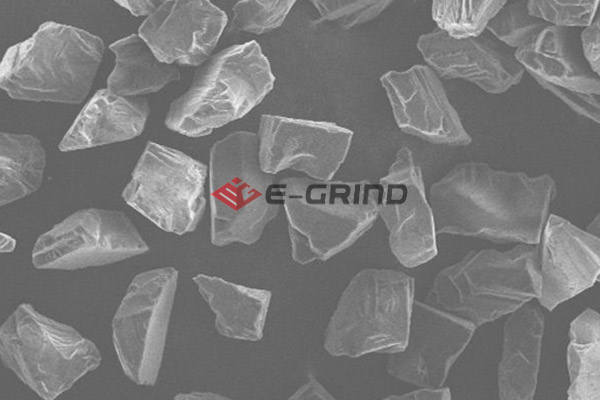

Polycrystalline diamond composite(PDC) sheet is made of diamond particles and cemented carbide matrix sintered at 60,000 atmospheres, high temperature and high pressure above 1500 ℃, and has the high hardness of diamond and the high toughness of cemented carbide. The diamond composite sheet has extremely high wear resistance, impact resistance and good thermal stability, and is specially used for oil drilling bits and can also be used for other rock or mining drilling operations.

Customized Diamond PDC

E-Grind can provide a full range of diamond PDC with diameters ranging from 8mm to 19mm. And we can also provider polycrystalline diamond compact cutters which can be customized according to customer needs.

Polycrystalline diamond composite

D+T is generally used to indicate product specifications

C is Diamond chamfer, the standard degree is 45°, 0.3 mm length.

Diamond table (t) thickness is 2.0 mm, 1.5 mm, 1.0mm.

Dimension can be customized according to customer needs

Available Spec for Oil/gas Grade

DT 16 13 10 8 4

19 * • * * o

16 * • * • o

13 o • * • •

10 o o • • •

8 o o o • •

Available Spec for Mining Grade

DT 16 13 10 8 4

19 o • * • o

16 o • * • o

13 o * * • •

10 o o • • •

8 o o o • •

Diamond-reinforced composite cutter are formed by sintering diamond particles and cemented carbide matrix at high temperature and pressure, which not only has the high wear resistance of diamond, but also has the high strength of cemented carbide. The products are widely used in roller cone bits, down-the-hole drill bits, picks, crushing machinery and other fields, and are the best substitute for cemented carbide cutter.

The diamond-reinforced composite cutter adopts the transition layer technology between the diamond layer and the cemented carbide layer, which has outstanding impact resistance and ultra-high wear resistance, making it widely used in high-end PDC bits, such as shock-absorbing cutter, Center cutter, gauge cutter, etc.

Henan E-Grind Abrasives Co., Ltd. was founded in 2009. However we have more than 50 years of experience in the superabrasiveindustry.

Send product request

Other supplier products

| Poly (Polycrystalline Diamond Powder) | Available sizes are 0-0.15, 0-0.2, 0-0.35, 0-0.5, 0.25-0.35, 0-1, 0-2, 2-4, 3-6, 3-7, 4-8, 4-9, 6-10, 6-12 Custom-made sizes are also availab... | |

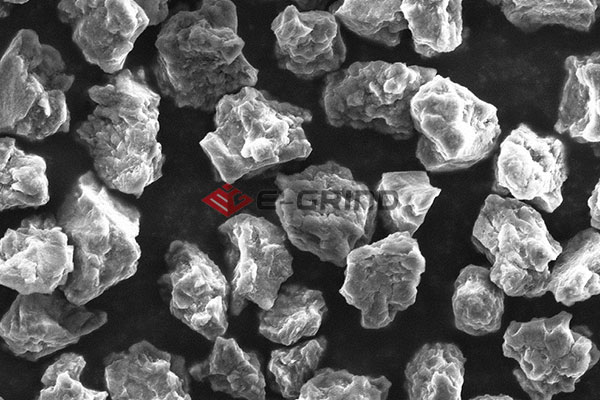

| Resin Bond Mesh Diamond | Friable Diamond Each Particle is with sub-crystal structure. Irregular and Very rough surface. New cutting edges come out during working. Also ava... | |

| Metal Bond Micron Diamond | Metal Bond Diamond Micron Powder Our metal bond micron products offer good Roughing, Lapping and finishing result. For resin bond, vitrified bond,... | |

| Diamond Powder | The diamond powder uses are wide. Industrial diamond powderhas the characteristics of high thermal stability, high chemical stability, good conduct... | |

| CBN Powder | The cubic boron nitride has a molecular formula of BN. Its atomic structure is similar to the structure of carbon atoms in diamond. Therefore, it h... |

Same products

| Micronized polypropylene wax for injection moulding | Seller: Syntop chemical Co.,Ltd. | The incorporation of polypropylene micronized wax into injection moulding processes delivers the ... | |

| Drum Type Mobile Mixing Station | Seller: Yousheng Machinery Equipment Co.,Ltd | Drum Type Mobile Mixing Station Drum Type Mobile Mixing StationPortable Drum Concrete Batch Plan... | |

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | Seller: XIUCHENG RFID | Size:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transf... | |

| Micronized wax used for industrial paint processing | Seller: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | Seller: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... |