The Evolution of Bottle Mould Technology: Shaping the Future of Packaging

Bottles have been an essential part of human life for centuries, serving as containers for liquids, powders, and various other substances. Over time, the design and production of bottles have evolved significantly, with bottle mould technology playing a pivotal role in this transformation. This article delves into the world of bottle moulds, exploring their history, technological advancements, and their impact on the packaging industry.

The Origins of Bottle Moulds

To understand the evolution of bottle moulds, we must first look back at their origins. Early civilizations relied on crude forms of containers made from clay, animal bladders, and natural materials. It wasn't until the invention of glassblowing in ancient Rome that the concept of molded bottles began to take shape. The craftsmanship required for these early glass bottles was labor-intensive and limited to the elite.

The Industrial Revolution and Moulding Innovation

The Industrial Revolution brought about a revolution in manufacturing processes, including bottle production. The invention of metal and ceramic moulds allowed for more standardized and efficient bottle production. This chapter explores the key innovations during this era and their impact on the availability of bottles for everyday use.

Plastics and the Birth of Injection Moulding

The 20th century ushered in a new era of bottle production with the invention of plastics. Injection moulding, a process that revolutionized the industry, enabled the mass production of plastic bottles. This chapter discusses the development of plastic materials, moulding techniques, and their influence on packaging.

Precision and Automation

Advancements in automation and computer-aided design (CAD) have further refined bottle mould technology. Modern moulds are designed with precision, allowing for intricate bottle shapes and sizes. Robotics and artificial intelligence (AI) play a significant role in optimizing production efficiency and quality control.

Sustainability and Eco-Friendly Materials

As environmental concerns grow, the packaging industry faces pressure to reduce its ecological footprint. This chapter explores how bottle mould technology has adapted to accommodate eco-friendly materials such as bioplastics and recycled plastics. It also discusses the importance of designing bottles for recycling and sustainability.

Customization and Personalization

Consumers increasingly seek unique and personalized products, leading to a demand for customized bottles. This chapter explores how bottle mould technology has evolved to enable mass customization, allowing brands to create distinctive packaging that resonates with their target audiences.

Future Trends and Challenges

The future of bottle mould technology promises exciting possibilities, including the integration of smart packaging, nanotechnology, and 3D printing. However, it also faces challenges such as stricter regulations, supply chain disruptions, and the need for continuous innovation.

Innovations in Material Science

One of the most exciting frontiers in bottle mould technology is the ongoing innovations in material science. Researchers are exploring new materials that are not only sustainable but also possess unique properties, such as enhanced barrier properties, lightweight construction, and improved durability. These materials can enable bottles to withstand extreme conditions and extend the shelf life of the products they contain. Advanced polymers, bio-based materials, and nanocomposites are just a few examples of the materials that hold the potential to revolutionize the packaging industry. Bottle mould technology will play a crucial role in adapting to and optimizing the production processes for these innovative materials.

Global Impact and Cultural Significance

Beyond the technical advancements and industrial applications, bottle mould technology has had a profound global impact and cultural significance. Bottles have become symbols of convenience, preservation, and even luxury. They carry the stories of different cultures and traditions, from ancient amphorae to contemporary glass artistry. Additionally, bottles have played pivotal roles in public health through the safe storage and transportation of potable water and medicines. Understanding the evolution of bottle mould technology allows us to appreciate not only the engineering marvels but also the profound cultural, economic, and environmental implications of this essential aspect of our daily lives.

- In conclusion, the evolution of bottle mould technology has been a journey from ancient craftsmanship to modern precision engineering. It has transformed the way we store, transport, and consume liquids and other substances. Looking ahead, the future holds exciting possibilities as bottle moulds continue to adapt to changing consumer preferences, sustainability demands, and emerging technologies. Whether it's a glass perfume bottle, a plastic water bottle, or a cutting-edge smart container, bottle mould technology remains at the heart of packaging innovation, shaping the future of how we interact with the products we use every day.bottle mould technology has come a long way since its humble beginnings. From ancient glassblowing to precision injection moulding, it has shaped the way we package and consume liquids. As we navigate the complexities of the 21st century, bottle mould technology will continue to evolve, addressing sustainability concerns and catering to consumer preferences. The future of packaging is being shaped by the continuous innovation in bottle moulds, ensuring that our bottles remain as diverse and essential as ever.

Send product request

Other supplier products

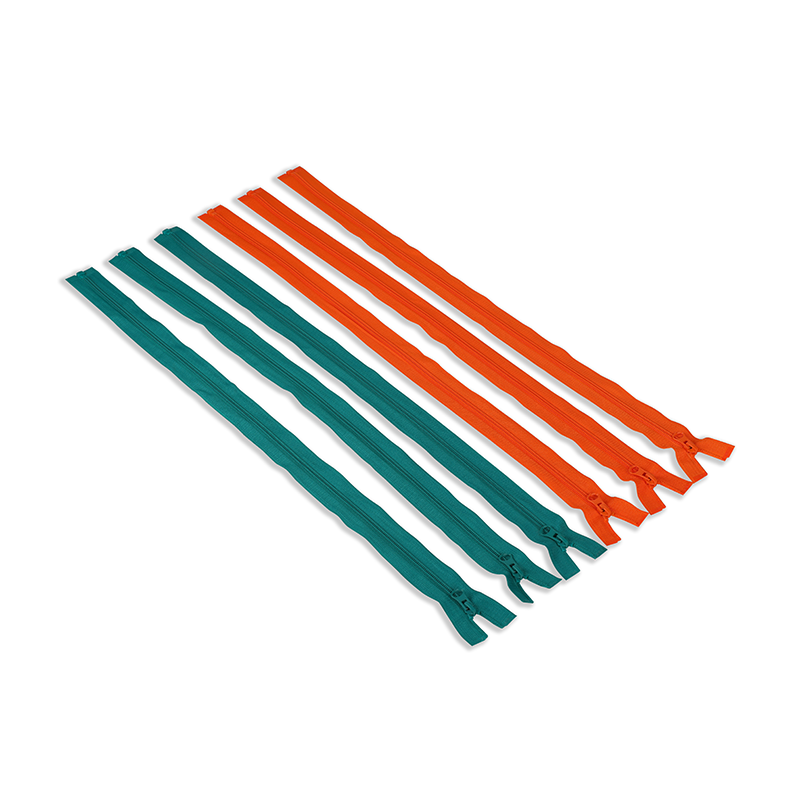

| Injection Molded Zipper | #7 opening injection molded zipper is crafted with high-quality materials using precision injection molding technology. This results in a zipper th... | |

| resorcinol-formaldehyde-resin-dh20 | Adhesive Agent is a versatile and indispensable product in the manufacturing and construction industries. It is a chemical substance designed to bi... | |

| Stainless steel kitchen floor drain airproof with grate and airproof cover | SZ110-20 200x200mm Stainless steel kitchen floor drain airproof with grate and airproof cover The main material:Stainless steel stretching and p... | |

| Satin floor drains | The application of our shower drains extends beyond mere utility; they are a statement of style and sophistication. With a variety of finishes, fro... | |

| lead-free Basin Mixers | 在追求健康安全的生活环境中,卫浴洁具的选择起着至关重要的作用。无铅面盆龙头 ( ) 已成为一项重要创新,确保保护个人和环境免受有害物质的侵害。本文探讨了无铅面盆龙头在浴室设计中的重要性及其对促进日常卫生习惯中的健康、安全和可持续性的贡献。 The Dangers of Lead in B... |

Same products

| Micronized wax used for industrial paint processing | Seller: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | Seller: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... | |

| Fungicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... | |

| Fungicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... | |

| Potassium Dihydrogen Phosphate (MKP) | Seller: Hebei Lvwang Ecological Fertilizer Co., Ltd. | Potassium Dihydrogen Phosphate (MKP) Potassium dihydrogen phosphate(MKP) is an efficient phospho... |