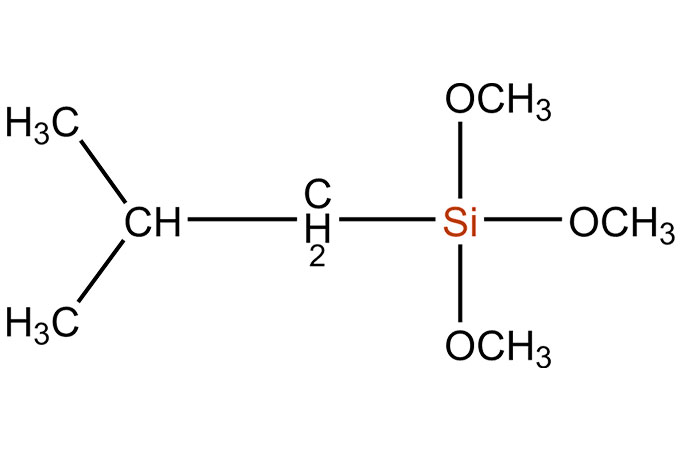

SiSiB® PC5951 Isobutyltrimethoxysilane

SiSiB® PC5951 is high purity, undiluted iso-butyltriethoxysilane. When diluted with an appropriate solvent, it can be used in the formulation of water repellent products. Upon proper application, the formulated product will penetrate and provide water repellency by chemically reacting with the cementitious substrate. Treated substrates are hydrophobic and retain their original appearance.

SiSiB® PC5951 silane surface modifier is a small molecule to allow for deep penetration into the construction materials (especially concrete and reinforced concrete) surface. This material reacts with moisture in the air and in the substrate in the presence of an alkaline or acidic environment to produce hydroxyl groups. These hydroxy groups will bond with the substrate and itself to produce a hydrophobic treatment that inhibits water absorption into the substrate. An alkaline environment, such as new concrete, will catalyze the reaction and speed the formation of the hydrophobic surface.

SiSiB® PC5951 is similar to DowCorning’s Z-2306 silane, Wacker’s IO-TRIMETHOXY, Evonik Degussa’s Dynasylan IBTMO.

Technical Data

|

CAS No. |

18395 30 7 |

|

EINECS No. |

242-272-5 |

|

Formula |

C7H16O3Si |

|

Molecular Weight |

|

|

Boiling Point |

156°C [760mmHg] |

|

Flash Point |

42°C |

|

Color and Appearance |

Colorless clear liquid |

|

Density25/25°C |

|

|

Refractive Index |

|

|

Purity |

Application

SiSiB® PC5951 can be used to render a wide range of surfaces and materials water repellent (e.g.construction materials, fillers), especially concrete and reinforced concrete.

SiSiB® PC5951 alkyl alkoxy silane should be diluted in solvents such as alcohols, chlorinated solvents, aliphatic solvents, and low molecular weight cyclic polydimethylsiloxane, such as SiSiB® CF1040 Fluid before use. Typical dilution levels are 40% and 20% SiSiB® PC5951 in a solvent.

Blends of the solvents can also be used. The evaporation rate of the diluted material can be modified depending on the type and concentration of the solvent. Select the proper solvent for your application, as some silane/solvent blends may darken the surface.

Methods of application include airless sprayer, roller and brush. When a brush or roller is used, repeated applications should be made until the surface remains moist for a few minutes. If an airless sprayer is used, application should continue until the substrate is thoroughly saturated. Sprayers should be fitted with solvent resistant hoses and gaskets. A test application is necessary on each surface to be treated to ensure compatibility and the desired water repellent result. Surfaces should be free of standing water, surface dirt, dust, oils, and other contaminants. The formulated SiSiB® PC5951 may be applied to damp surfaces although dry surfaces are preferred to achieve maximum penetration into the substrate.

Like SiSiB® PC 5901 n octyltrimethoxysilane, SiSiB® PC5951 can also be used as a surface modifier to generate hydrophobicity and to increase compatibility to organic non polar matrices.

SiSiB® PC5951 can be used in the production of silane crosslinking formulations.

SiSiB® PC5951 can be used as a component for the manufacture of Ziegler-Natta Catalysts.

Packing and Storage

SiSiB® PC5951 is supplied in net weight 180Kg steel drum.

In the unopened original container SiSiB® PC5951 has a shelf life of one year in a dry and cool place.

As a silicone products manufacturer, we can offer sorts of related products for sale, if you are interested, please contact us.

Send product request

Other supplier products

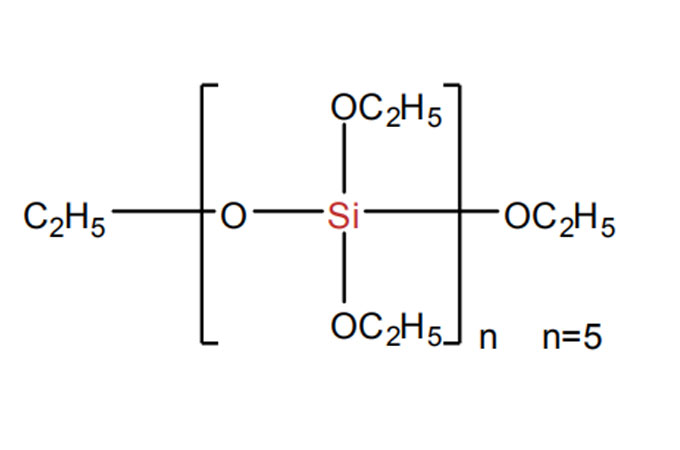

| SiSiB® PC5424 Ethylpolysilicate 40 | SiSiB® PC5424 EthylSilicate 40 SiSiB® PC5424 is a hydrolyzed and oligomerized form of ethyl silicate. It is a mixture of monomers, dimers... | |

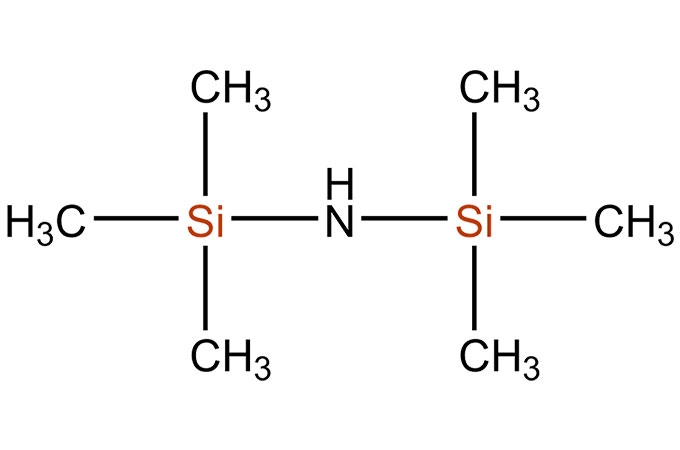

| SiSiB® PC9210 | Hexamethyldisilazane SiSiB® PC9210 (also called as Bis trimethylsilyl amine; HMDS chemical; HMDZ) is an extremely versatile and strong silylat... | |

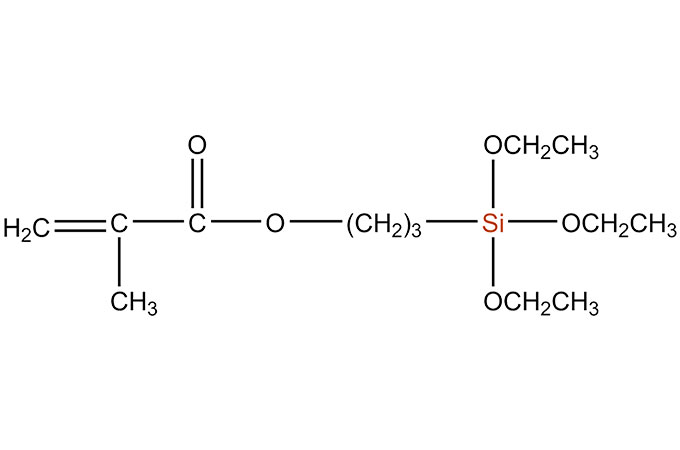

| SiSiB® PC4200 3-Methacryloxypropyltriethoxysilane | SiSiB® PC4200 is a methacryl-functional silane; it is a clear, light and heat sensitive liquid with a faintly sweet odour. It is the equivalent... | |

| PU Foam Silicone Stabilizer | SiSiB develops and manufactures a full line of high-qualitysilicone oil surfactantfor formulating polyurethane rigid foams, flexible foams, high re... | |

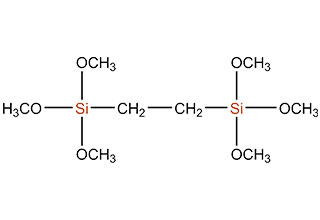

| SiSiB® PC6112 1,2-Bis(trimethoxysilyl)ethane | SiSiB® PC6112 12Bistrimethoxysilylethane SiSiB® PC6112 (BTMSE) and SiSiB® PC6122 (BTSE) are clear to straw bis-silanes. SiSiB&re... |

Same products

| Fully Premixed Condensate Hot Water System | Seller: Hebei Qintai Thermal Power Equipment Co., Ltd | Fully Premixed Condensate Hot Water System The burner used in the equipment adopts the self-deve... | |

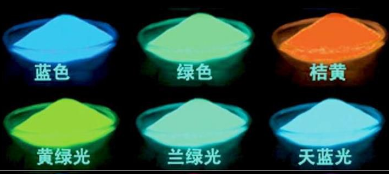

| Jingduo pignmet | Seller: Jingduo Guang - L year GuangZhou Twiise. A-鹏 A--Hissnissens海灯 | ||

| Flat Knitting Patellar Strap with Silicone Pad | Seller: Zhejiang Steriger Sports Medicine Technology Co., Ltd. | Zhejiang Steriger Sports Medicine Technology Co., Ltd. presents the Flat Knitting P... | |

| Luminous pigm | Seller: Jingduo Guang - L year GuangZhou Twiise. A-鹏 A--Hissnissens海灯 | ``Dan qin cha ban sheng`` if hears`s so you love. | |

| graphite target | Seller: Advanced Targets Materials Co., Ltd | graphite target Graphite Target are widely used in the Physical Vapor Deposition (PVD) proc... |