Water Conveying Belt Unit

With frequency conversion control, equipped with corresponding head, the machine unit can produce layflat width of 40-320 mm double-layer composite hose, the thickness of products: 0.2-2 mm, production speed: 2-20 m/min.

This machine unit adopts new technology, reducing the production costs and improving the production efficiency greatly. Even if the Water Conveying Belt Unit uses the reworked material, its bearing capacity is much higher than the same products with traditional process using new material. The products has consistent specification and uniform thickness, without the explosive belt.

■ Technical Data

Double-layer composite hose features:

1. rational structure and advanced technology.

2. recycling and utilization of waste resources, saving costs, environment protective.

3. high effiency and low energy consumption.

4. CE certification, reliable quality

Other supplier products

All supplier products

Same products

|

|

FMS888-1S Stainless Steel Industrial Box Change Locks |

Seller: Ningbo Oubao Technology Co., Ltd. |

Material: stainless steel base, handle, cover plate, rotating shaft, steel bolt Surface treatme... |

|

|

Wear-Resistant Breathable Artificial Synthetic Leather For Interior Decoration |

Seller: Fu\\\'an Synthetic Materials Co.,Ltd. |

This Wear-Resistant Breathable Artificial Synthetic Leather for Interior Decoration is made from ... |

|

|

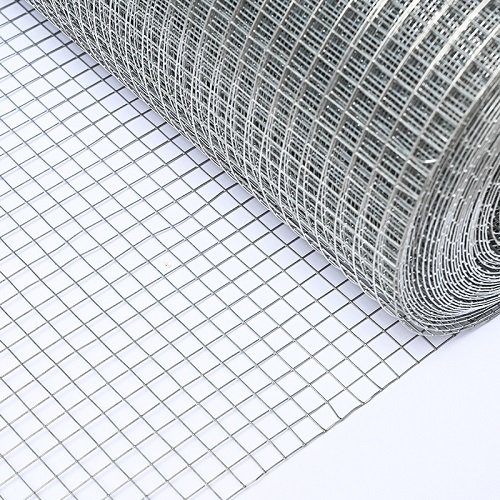

Welded Wire Mesh Net |

Seller: Jiaohao Wire Mesh Products Co., Ltd. |

Constructed by fusing metal wires at their intersection points, welded wire mesh panels are mad... |

|

|

Steel Grating |

Seller: Jiaohao Wire Mesh Products Co., Ltd. |

Made from carbon steel, stainless steel or hot-dip galvanized steel with a galvanized surface t... |

|

|

Chain Link Fence |

Seller: Jiaohao Wire Mesh Products Co., Ltd. |

Chain link fence also known as cyclone fence, it is an elastic woven net. Thiswire mesh product... |