Falling-film Evaporator

Effectively reduce the tower kettle temperature and improve product quality and yield.

Technical Principle of Falling-film Evaporator

Characteristics of Falling-film Evaporator

1

Design conditions:

We use the most safe and stable falling film reboiler model in present day, and the falling film introduces the multi-level distribution form including the distribution plate and the film distribution header.

2

Process Calculation:

Based on the calculation of advanced simulation software, key parameters such as gasification rate, circulation volume, flooding factor, gas-phase rate, heat exchange area, etc. are determined.

3

Distributor/Calculation of Film Distribution Header:

Various hydraulic models are conducted to design distribution system under specific operation conditions, further more hydraulic calculation is operated with independent software.

4

With rich experience and advanced technology, DODGEN falling film evaporator has been applied in various fields of heat-sensitive substances separation, the temperature of tower kettle is reduced, thus improving product quality and yield, and obtaining positive feedback from customers.

Applications of falling film evaporator china

In the evaporation and rectification section of heat sensitive substances, MVR system evaporator is particularly suitable for typical applications,such as:

MDI distillation

Vitamin E rectification

Ethylene glycol distillation

Hydrogen peroxide rectification

Nylon 11 distillation

Solvent recovery

MVR evaporation

And many other fields such as petrochemical, medicine and food.

As a falling film evaporator suppliers, We provide falling film reboiler design, chemical process video, etc. For more about falling film evaporator definitionand how does film evaporator function, contact us.

Send product request

Other supplier products

| Melt Crystallization | Accurately control the temperature and integrate a number of technologies for efficient purification. Technical Principle Of Melt Crystallizatio... | |

| Micro Reactor | Technical Principle Of Micro ReactorComposition of D-AMERT high flux microreactor:Transfer metering unit —Temperature control unit—micr... | |

| Melt Crystallizer | Accurately control the temperature and integrate a number of technologies for efficient purification. Characteristics of Melt Crystallizer 1 H... | |

| Extraction Tower | Extraction process definition Advanced liquid-liquid extraction tech, solving separation problems and providing economical solutions Technical ... | |

| Column Internals | A strict quality management system guarantees the product quality and delivery time of the project. Characteristics of tray column internals 1 ... |

Same products

| Nozzle Sprayer DLLA147PV3A005T5 Nozzle Sprayer DLLA147P27BJ | Seller: China lutong | Nozzle Sprayer DLLA147PV3A005T5 Nozzle Sprayer DLLA147P27BJChris Whats/ app:+8–6–1&n... | |

| FMS888-1S Stainless Steel Industrial Box Change Locks | Seller: Ningbo Oubao Technology Co., Ltd. | Material: stainless steel base, handle, cover plate, rotating shaft, steel bolt Surface treatme... | |

| Wear-Resistant Breathable Artificial Synthetic Leather For Interior Decoration | Seller: Fu\\\'an Synthetic Materials Co.,Ltd. | This Wear-Resistant Breathable Artificial Synthetic Leather for Interior Decoration is made from ... | |

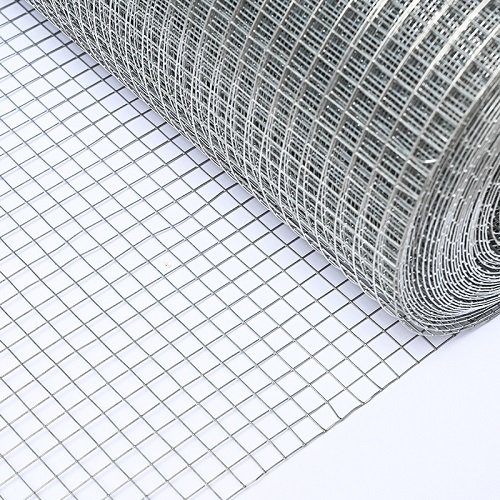

| Welded Wire Mesh Net | Seller: Jiaohao Wire Mesh Products Co., Ltd. | Constructed by fusing metal wires at their intersection points, welded wire mesh panels are mad... | |

| Steel Grating | Seller: Jiaohao Wire Mesh Products Co., Ltd. | Made from carbon steel, stainless steel or hot-dip galvanized steel with a galvanized surface t... |