Latest Developed Dry Powder Briquette Machine for Sale

Latest developed dry powder briquette machine for sale can make briquettes from a wide range of powdery materials, including carbamide, pigment, calces, plastic, chemical fertilizer, cryolite, coal, coke powder, clay, caustic soda (sodium hydroxide), alumina, active charcoal powder, ore dust, iron ore, magnesium powder, aluminum powder and many other mineral powder materials. Unlike ordinary briquettes, dry powder briquettes need no binder during briquetting process.

The latest developed dry powder briquette machine for sale is mainly characterized by high pressure, high briquetting success rate, stable performance, low energy consumption and no pollution. In addition, the finished briquettes boast high strength, and are unbreakable property during the process of transportation or smelting.

With this latest developed dry powder briquette machine for sale, mineral powder wastes can be recycled and compressed into useful and high-density briquettes which are small in size and convenient for transportation. Raw Material and Attention Lime, alumina or aluminium powder, magnesium powder, ore powder, coke, bauxite, pigment, cryolite, chemical fertilizer, caustic soda or sodium hydroxide, clay, coke, coal etc without using binder. Material should be less than 80-200mesh.There shouldn’t be any metallic material in the raw material to avoid damaging the surface of rollers. Sufficient supply of raw material to make perfect and good-looking briquette.

Requirements on Briquetting Process Flow

Ensure the feeding system to be continuous, uniform and stable. Since the hopper of the machine is filled with raw materials, overflow pass is necessary in the feeding system. During the briquetting process, the exhaust port of the feed hopper on the briquette machine should be connected with dust removal pipes to make the gas discharged. During the briquetting process, the new materials must be proportioned with some crushed and returned materials, if the returning materials are inadequate, it will be difficult for briquetting, especially for the materials hard to form briquette.

Working Principle of Latest Developed Dry Powder Briquette Machine for Sale:

The working process of this machine can be divided into three parts – pre-pressing, pressing and de molding.

Pre-pressing: Above the rollers, there is a rotating screw device driven by variable-speed motor to pre-press the material.

Pressing: After pre-pressing, the material will be forced into the double rollers. This stage can also be called degassing.

Demoulding: After the mould closed, with the roller rotating, the briquettes will be demoulded automatically.

Spare Parts of Latest Developed Dry Powder Briquette Machine for Sale

Contact Infomation

Phone:

Email:

Website:

Address: High and New Industrial Zone, Kexue Revenue, High and New Technology Industrial Development Zone, Zhengzhou, China

Send product request

Other supplier products

| Briquetting Press Manufacturers/Briquetting Machinery | Briquette machine is also called briquette press machine. This hydraulic briquette machine can briquetting all kinds of wood wastes, straw stalk, s... | |

| Corn Stover Pellet Press Price/Excellent Corn Stover Pellet Mill | In recent years, biomass pellets have become popular as a heating fuel to replace traditional fuels, like coal, natural gas and petrol. The pellets... | |

| Hot Selling High Efficient Wood Pellet Mill Price | Hot selling high efficient wood pellet mill price, as the best bio pellets making machine, is the preferred pelletizing equipment in the biomass en... | |

| Reliable Quality Biomass Briquette Machine Price | To start a reliable quality biomass briquette machine or a briquetting plant, investment in raw material counts little, even free to obtain if you ... | |

| Artificial Sand Making Machine Cost/Construction Sand Making Machine | Sand making machine demand is increasing every year,this is the trend of the world economy, but also that Sand really brought benefits to the commu... |

Same products

| Plant Growth Regulator Manufacturer | Seller: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... | |

| Fungicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... | |

| Fungicide Supplier | Seller: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... | |

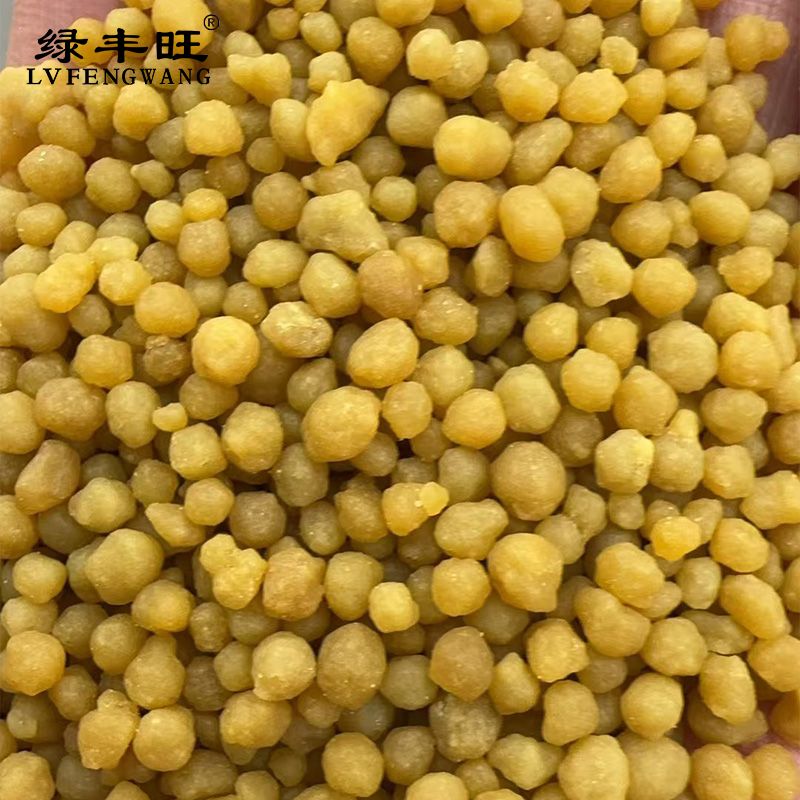

| Potassium Dihydrogen Phosphate (MKP) | Seller: Hebei Lvwang Ecological Fertilizer Co., Ltd. | Potassium Dihydrogen Phosphate (MKP) Potassium dihydrogen phosphate(MKP) is an efficient phospho... | |

| DAP 18-46-0 Diammonium Phosphate Fertilizer for Agriculture | Seller: Hebei Lvwang Ecological Fertilizer Co., Ltd. | DAP 18-46-0 Diammonium PhosphateFertilizer for Agriculture DAPis used as a phosphorus fertilizer... |