Hide Gelatin Votator KDVT

If you are checking hide gelatin votator kdvt price, or looking for cheap high torque hide gelatin votator kdvt, hide gelatin extruder, hide gelatin heat exchanger, hide gelatin extrusion system, hide gelatin votator heat exchanger, hide gelatin extrusion equipment, hide gelatin extruding machine, hide gelatin votator heat exchanging machine, welcome to contact KODI Machinery, we are one of the leading China hide gelatin votator kdvt manufacturers.Quick DetailsCondition: NewPlace of Origin: Jiangsu, China (Mainland)Brand Name: KODIModel Number: NoStructure: votatorLiquid Flow Rate: due to your requirementMaximum Working Pressure: VariableVoltage: 220v-450vWeight: Deponds on the modelDimension(L*W*H): Deponds on the modelPower(W): 15-22kwCertification: CEWarranty: 1 yearAfter-sales Service Provided: Engineers available to service machinery overseasProduct Name: Skin Gelatin Extruder/Scraped Surface Heat Exchangers/VotatorGelatin capacity: 750-2000 ton/yearHeat exchanger area: 0.5-1.4 ㎡Product rate: 110-300 kg/hFeed rate: 400-1200 kg/hFeed concentration: 24-30 %Chilled brine ( -10℃): 35-80 m³/hPower: 15-22 kwInstallation: KODI serviceSpare parts: Supply the whole lifetimePackaging & DeliveryPackaging Details:Skin gelatin extruder / Skin gelatin votator /Skin gelatin heat exchanger is packing with plywood box or As customers' requirementDelivery Detail:40-90daysSkin Gelatin Extruder/Scraped Surface Heat Exchangers/Votator 1, Skin gelatin extruder / Skin gelatin votator / Skin gelatin heat exchanger2, Stainless steel3, Automatic control, temperature auto-control, automatic oscillating4, GE standard5, Easy operation Product DescriptionWhat is SkinSkin is the soft outer covering of vertebrates. Other animal coverings such as the arthropod exoskeleton have different developmental origin, structure and chemical composition. The adjective cutaneous means "of the skin" (from Latin cutis, skin). In mammals, the skin is an organ of the integumentary system made up of multiple layers of ectodermal tissue, and guards the underlying muscles, bones, ligaments and internal organs.Skin of a different nature exists in amphibians, reptiles, and birds. All mammals have some hair on their skin, even marine mammals which appear to be hairless. The skin interfaces with the environment and is the first line of defense from external factors. For example, the skin plays a key role in protecting the body against pathogens and excessive water loss.Its other functions are insulation, temperature regulation, sensation, and the production of vitamin D folates. Severely damaged skin may heal by forming scar tissue. This is sometimes discoloured and depigmented. The thickness of skin also varies from location to location on an organism. In humans for example, the skin located under the eyes and around the eyelids is the thinnest skin in the body at 0.5 mm thick, and is one of the first areas to show signs of aging such as "crows feet" and wrinkles. The skin on the palms and the soles of the feet is 4 mm thick and the back is 14 mm thick and is the thickest skin in the body. The speed and quality of wound healing in skin is promoted by the reception of estrogen.Fur is dense hair.Primarily, fur augments the insulation the skin provides but can also serve as a secondary sexual characteristic or as camouflage. On some animals, the skin is very hard and thick, and can be processed to create leather. Reptiles and fish have hard protective scales on their skin for protection, and birds have hard feathers, all made of tough β-keratins. Amphibian skin is not a strong barrier, especially regarding the passage of chemicals via skin and is often subject to osmosis and diffusive forces. For example, a frog sitting in an anesthetic solution would be sedated quickly, as the chemical diffuses through its skin. Amphibian skin plays key roles in everyday survival and their ability to exploit a wide range of habitats and ecological conditions. Description of Skin Gelatin VotatorSkin gelatin votator is also called Votator, which is applied to gel the glue from evaporator. The KODI designed extruding system is stable and does good performance in abrasion resistance. And gelled gelain is clear and clean with hollow inside. The special designed structure greatly prevent the gelling from being polluted by bacteria. Characteristics of Skin Gelatin ExtruderSkin gelatin extruder is for application in the gelatin gelled for drying. It is a scraped surface heat exchanger. The gelatin flows through a jacket cylinder containing a rotating central shaft on which the scrape blades are mounted with the flowing of cooling medium in jacket. The gelatin is chilled and gelled and being extruded in noodle form and spread evenly onto dryer by self-oscillating. It keeps the gelatin free of being polluted by bacteria during convey by belt conveyer. The oscillating votator is the patent newly developed by our company.Capacity: Gelatin 750~2000T/YControl Mode:Automatic control, temperature auto-control, automatic oscillatingThe Main Fittings of Skin Gelatin Heat ExchangerSkin gelatin heat exchanger, oscillating system, feed pump, frame structure, pipeline and temperature are automatic control. It is made of high quality stainless steel.Technical Parameter of Skin Gelatin Votator/ ExtruderItemModel Heat exchange area m²0.50.80.91.4Product rate kg/hFeed rate kg/hFeed concentration %24~30Chilled brine -10℃ M³/h35406080Power kw15182222Successful Project of KODI Skin Gelatin Heat ExchangerAbout Gelatin Gelatin is a protein substance derived from collagen, a natural protein present in the tendons, ligaments, and tissues of mammals. It is produced by boiling the connective tissues, bones and skins of animals, usually cows and pigs. Gelatin's ability to form strong, transparent gels and flexible films that are easily digested, soluble in hot water, and capable of forming a positive binding action have made it a valuable commodity in food processing, pharmaceuticals, photography, and paper production.Gelatin Production MethodsStep 1: The material that actually becomes gelatin is collagen. This is only found in high enough concentrations to be useful inside skin and bones. As a result, the first step in gelatin production is cleaning the starter materials in KODI Gelatin washing tanks. Any leftover debris, such as fat, hair or meat, is thoroughly scrubbed from the skin and bones. This reduces the chance of contaminants, which creates a purer product and easier extraction. Step 2: This next part of gelatin production is where the methods begin to diverge in KODI Gelatin acid tanks or KODI Gelatin Alkaline tanks. The base material is soaked in a solution, which begins to break down the links between the collagen and other materials using one of three basic soaking methods: acidic, alkaline and enzymatic. Acidic methods for gelatin production typically take one to two days and work the best on hides. Alkaline methods can take weeks but will work on nearly any valid material. Lastly, enzymatic processes are somewhat new but work very fast and produce high purity in the few places equipped to use them.Step 3: The rest of the gelatin production process is done fairly quickly. After the soaking in KODI Gelatin soaking tanks, the collagen is pulled from the base material using water. Alkaline water will pull the material faster, but will also damage the gelatin, so neutral or acidic water is generally used. Heat will also damage the collagen but will generally pull out more material, so washing is done in waves. The process starts with cold water but gradually gets warmer to get as much out as possible. Step 4: The last step processes the collagen into full-fledged gelatin. This part of gelatin production varies wildly based on the previous steps, but it typically involves cold temperatures, filtration and air drying systems. Here we normally need to use KODI gelatin membrane filter, KODI gelatin belt dryer/ Band dryer. Different pH levels and ambient temperatures during soaking have a large impact on the solidity and quantity of the final product. KODI company will supply you a Turnkey skin/hide/bone gelatin production line and Gelatin machinery.Hide Gelatin Simple flow chart Main Equipment of Gelatin Production Line

Other supplier products

|

|

Stainless Steel Horizontal Leaf Filter XY-W |

If you are checking stainless steel horizontal leaf filter xy-w price, or looking for cheap high torque stainless steel horizontal leaf filter xy-w... |

|

|

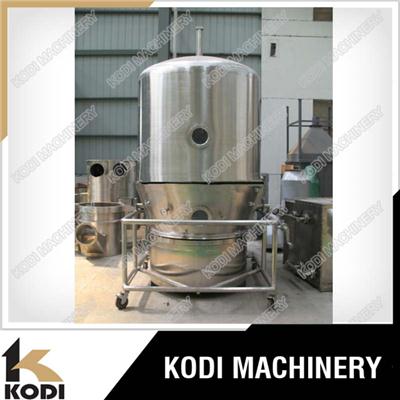

Glutamate Fluid Bed Dryer ZLG |

If you are checking glutamate fluid bed dryer zlg price, or looking for cheap high torque glutamate fluid bed dryer zlg, welcome to contact KODI Ma... |

|

|

Coffee Granule High Efficiency GFG |

If you are checking coffee granule high efficiency gfg price, or looking for cheap high torque coffee granule high efficiency gfg, welcome to conta... |

|

|

U-shaped Ribbon Mixer WLDH |

If you are checking u-shaped ribbon mixer wldh price, or looking for cheap high torque u-shaped ribbon mixer wldh, welcome to contact KODI Machiner... |

|

|

Foodstuff Superfine Pulverizer WFJ |

If you are checking foodstuff superfine pulverizer wfj price, or looking for cheap high torque foodstuff superfine pulverizer wfj, welcome to conta... |

All supplier products

Same products