Plastic Extruder & Pelletizer For Masterbatch

Masterbatch is one important part of the plastic industry. As a professional extruder supplier and manufacturer, Nanjing KY knows a lot about masterbatch and masterbatch production, and supplies high-quality masterbatch extrusionmachines.

What is Masterbatch?

Masterbatch is an indispensable part of the plastic industry. It can not only give colorful plastic products, improve the value of commodities, improve some properties of plastics, but also give special optical properties of materials.

In the preparation of masterbatch, resin, pigments, additives (dispersants, light stabilizers, etc.) need to be dispersed and distributed efficiently and stably through mixing equipment to ensure that all kinds of materials with different components are evenly distributed in the resin. The masterbatch blending and masterbatch extrusion system of Nanjing KY Chemical Machinery Co., Ltd. is very suitable for masterbatch operations with different colors, such as black, white, and other colors, and different binders, such as PE, PP, PA, ABS, PET, POM, TPE, TPU, etc. Nanjing KY can provide customers with masterbatch machineof high quality.

Nanjing KY, as one of the professional twin screw extruder suppliers, can provide customers with complete extruder pelletizerand masterbatch extrudersolutions, from material transportation, metering feeding, extrusion, granulation, drying, to material packaging.

KY has rich technology accumulation, can provide a customized design to customers according to their prescription requirements, and provide customers with the most suitable solutions and equipment.

What is Masterbatch Extruder?

Masterbatch extruder and pelletizeris an essential machine in the plastic manufacturing industry, especially in the production of color masterbatch. Color masterbatch is a concentrated mixture of pigments, additives, and carriers that are added to natural resins to impart a particular color or enhance their properties. The color masterbatch pe extruder machineis used to produce color masterbatch in large quantities with high efficiency and accuracy.

A masterbatch machine is a specialized extrusion machine that is designed to create masterbatch pellets. The machine can be used to create both standard and custom color masterbatch. The masterbatch extruder works by melting the resin and mixing it with the pigments and additives in a controlled environment to create a homogenous mixture. The mixture is then extruded through a die to create pellets, which are cooled and collected.

The color masterbatch extruder machine is typically designed with a modular screw system that can be easily modified to accommodate different formulations and production requirements. The screw system is responsible for the mixing and homogenization of the ingredients. The extruder's temperature, speed, and pressure can be precisely controlled to ensure consistent quality and uniformity in the final product.

Masterbatch extrusion is a critical process in the production of color masterbatch. The extruder machine must be able to handle high volumes of material and maintain a consistent mixing ratio. The quality of the final product depends on the accuracy of the mixing process and the quality of the raw materials used.

A color masterbatch extruder is a specialized type of masterbatch extruder that is designed to produce colored masterbatch. The color masterbatch extruder uses specialized pigments and additives that are formulated to produce a specific color or effect. The color masterbatch extruder machine is typically equipped with additional components such as a feeder and a dosing unit to ensure accurate color matching and consistency.

A color masterbatch extrusion line is a complete production line that includes all the equipment necessary to produce color masterbatch pellets. The line typically includes a color masterbatch extruder, a feeder, a dosing unit, and a cooling system. The color masterbatch extrusion line can be customized to meet the specific production requirements of the manufacturer.

In conclusion, masterbatch extruder machines are essential equipment in the plastic manufacturing industry, and color masterbatch extruder machines are specifically designed to produce colored masterbatch. The machines use a modular screw system to melt and mix the raw materials and extrude them into pellets. The color masterbatch extruder machine is designed to handle high volumes of material and maintain a consistent mixing ratio to produce a uniform and high-quality final product. A color masterbatch extrusion line includes all the equipment necessary to produce color masterbatch pellets and can be customized to meet specific production requirements.

Masterbatch Production Process

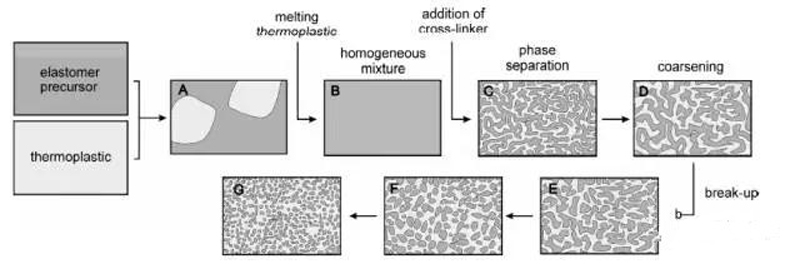

The masterbatch production process is very strict and generally adopts a wet process. Color masterbatch material is produced by water grinding, phase, water washing, drying, and granulation. Only in this way the quality of products can be guaranteed.

In addition, while the pigment is grinding, a series of tests should be carried out, such as the determination of the fineness of the grout, the determination of the diffusion performance of the grout, the determination of the solid content of the grout, and the determination of the color paste fineness and other items.

With more than 20 years of industry experience and installation practice of more than 8000 production lines, Nanjing KY Chemical Machinery Co., Ltd. provides global customers with optimal cost performance and reliable compouding extrusion systems. Our twin screw extrusion machine models range from laboratory test samples by using lab scale twin screw extruderto polyolefin granulation engineering for petrochemical enterprises to meet the latest needs of various related industries.

Send product request

Other supplier products

| Plastic Extruder For Thermoplastic Elastomer | Mixing Modification of Elastomer——Blending Modification of SBS/SEBS Applications of Thermoplastic Elastomer: The English acronym ... | |

| HKY / SKY Two Stage Extruder | HKY / SKY series two-stage extrusion system: the first stage is HK or SK series high speed and high torque co-rotating twin screw extruder, the sec... | |

| HK Large Extruder Production System | KY also offers a larger-scale HK twin screw extruder, with the commonly used screw diameters ranging from 110 mm to 165 mm (HK110-165) available fo... | |

| Screw Element | The plastic extruder screwall component materials are supplied by domestic first-line brands or European professional materials suppliers of twin-s... | |

| Biodegradation Recycled Plastic Extruder Machine | Biodegradable plastics refer to a kind of plastic that is degraded by natural microorganisms such as bacteria, fungi, and algae. The ideal biodegra... |

Same products

| Low Smoke ZERO Flame Retardant Polyolefin Sheath Compound | Seller: Hebei Sunua Advanced Material Co. Ltd. | Low Smoke ZERO Flame Retardant Polyolefin Sheath Compound Low Smoke ZERO Halogen LSZH Compou... | |

| diesel common rail nozzle DLLA152P1060 | Seller: China Lutong Part Plant | diesel common rail nozzle DLLA152P1060 Tina Chen service for you. Whatsapp/ common rail nozzle D... | |

| Saudi Acoustic Wood Slats | Seller: Suzhou Deco Sound New Materials Technology Co., Ltd | Saudi Acoustic Wood Slats Acoustic Panels for Home Theaters Create the with Deco Sound's pr... | |

| Textile Pigment Ink | Seller: INKBANK Group Inc. | Textile Pigment Ink Textile Pigment Ink contains adhesives and binders that fix the color t... | |

| sintered filter disc | Seller: ZHUAN LV FILTRATION | sintered filter disc Sintered Filter Disc A range of stainless steel fibre and Sintered Fil... |