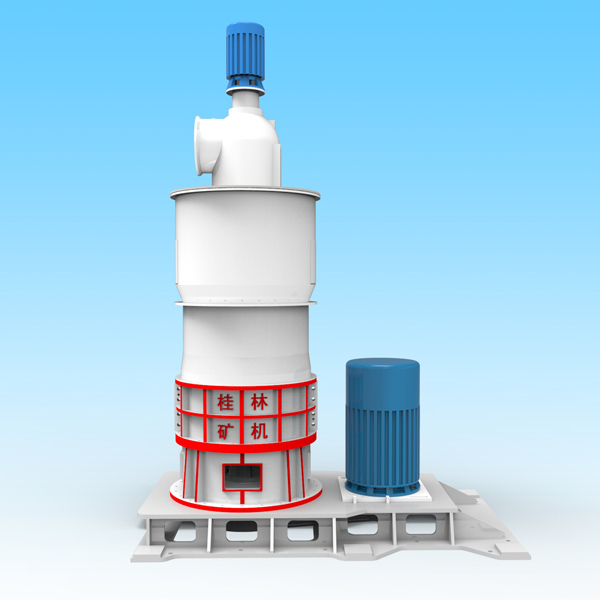

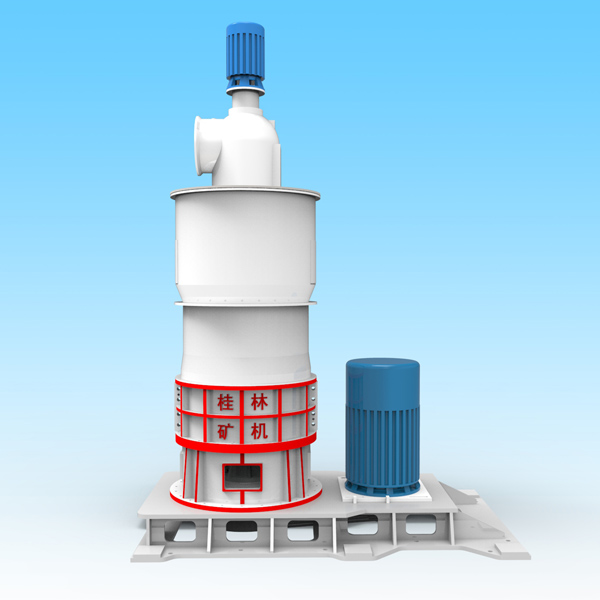

Ultrafine Mill

GKH1032D Ultrafine Ring Roller Mill is a developed kind of grinding mill with optimized design & structure. It is mainly used in deep processing non-metallic mineral stones, hardness below seven Moh's hardness and humidity below 6%, such as calcium carbonate, kaolin, talc, barite, grammite, feldspar etc. The GK1032D mill mainly consists of the feeder, main unit, classifier, pulse collector, high-pressure blower, electrical control cabinet etc.

GKH 1032D Ultrafine MillTechnical & Structural Benefits:

Compared with the same type of ultrafine mill, GK1032D is highly featured with the lower vibration, easier maintenance, more wearable spare parts and lower operating cost.

GKH 1032D Ultrafine Mill Main Techincal Date:

|

Item |

GKH1032D |

|

|

Power(KW) |

Main unit(mill) |

132 |

|

Classifier |

30 |

|

|

Fan |

90 |

|

|

Roller layer |

4 |

|

|

Roller QTY(pcs) |

32 |

|

|

output size(um) |

3-35 |

|

|

Capacity(kg/h)(for different output size) |

800-5000 |

|

|

Weight of main unit(mill) |

||

Theultra fine grinding equipmentis mainly used for crushing equipment for metallurgy, building materials, chemical industry, mining and other mineral materials.

The grinding range of the ultrafine mill is a variety of non flammable and explosive mineral materials, such as quartz, feldspar, porcelain clay, clay, bentonite, calcite, barite, fluorite, ball clay, white mud, gypsum and so on, the Moh's hardness of which is below 7 level and the humidity of which is below 6%. The size range of the finished product by the mill is about 325 mesh -1800 mesh (the size can be adjusted according to different requirements).

The Characteristics of the Ultrafine Mill

The noise and the vibration are small;

The pressure is heavy and the fine powder is much;

The attrition of the grinding ring and grinding roller are both even. They have long service life, which is 3-5 times than that of the ordinary Raymond mill;

Ultrafine grinderis suitable for processing hard material;

The iron content in the micro powder is low;

It can be operated continuously without affecting the oil injection in the grinding roller bearing house of the mill;

It has small power consumption, high efficiency, and easy installation and maintenance;

There is scraper feeding in the mill, so the production efficiency is greatly improved.

The Application ranges of the Ultrafine Mill

Centrifugal ultrafine mill is mainly suitable for processing the barite, calcite, limestone, kaolin, bentonite, marble, gypsum, refractory material, quartz stone, glass, ceramics and others minerals of high fine powder, the hardness of which is less than 9.3 level and the humidity of which is less than 6%. The grain size is about 80mesh -1500 mesh (the size can be adjusted according to different requirements).

The Technical Advantage of the Ultrafine Mill

The utilization rate of wear materials is high, which is four times the service life of Raymond mill;

The processing of fine sand is more effective than other mills;

Ultra fine grinding millis a kind of high-efficiency equipment for power plant desulphurization;

It can be used to grind before ball milling, the milling efficiency can be increased by 50%;

It is mainly used for all kinds of brittle materials that can be crushed, and the hardness is less than that of Mori's hardness 9 level.

The Comprehensive Characteristics of the Ultrafine Mill

high efficiency. Under the circumstance of the same product size, the output is 40% higher than that of other mills;

The utilization rate of the vulnerable parts is high. When the material and finished product have the same particle size, the service life of the wearing parts is longer than that of other mining machinery;

High safety and reliability. The mill is designed rigorously, and there is no problem of screw loosening and destroying the machine;

Clean and environmental. The use of pulse dust remover and muffler reduces dust pollution and noise. So it achieves national environmental standards.

Send product request

Other supplier products

| GK-PSH Type Water Spray Dedusting Lime Slaker | GK-PSH Type Water Spray Dedusting Lime Slaker Model: A type C typeE type based on different lime slaker capacity GK-PSH Type Water Spray Dedusting... | |

| GK-PSH Type Water Spray Dedusting Lime Slaker | GK-PSH Type Water Spray Dedusting Lime Slaker Model: A type C typeE type based on different lime slaker capacity GK-PSH Type Water Spray Dedusting... | |

| Ball Mill | The Handling Materials and Main Types of Ball Mill: Industrial ball millsis a key equipment for grinding materials, widely used in powder-making pr... | |

| Micro Powder Mill | GKW Micro Powder Millis mainly used in chemical industry such as grinding glass, rubber, pesticides, enamel, paint, phosphate fertilizer, paper. Ha... | |

| GK-PSC Type Water Spray Precipitator | This equipment is one of the necessary equipment for the lime digester. GK-PSC Type Water Spray Precipitator characters: It adopts natural water c... |

Same products

| PLMFKA Pneumatic Roller Mill | Seller: Hebei Pingle Grain Technology Intelligent Equipment Co., Ltd | Type: Pneumatic Roller Mill and E-control Roller Mill Model: PLMFKA100×25×4PLMFKA125... | |

| PLMFP E-Control Roller Mill | Seller: Hebei Pingle Grain Technology Intelligent Equipment Co., Ltd | Type: Pneumatic Roller Mill and E-control Roller Mill Model: PLMFKA100×25×4PLMFKA125... | |

| ASTM A789/ASME SA789 DUPLEX STEEL PIPE/TUBE | Seller: YUHONG GROUP CO., LIMITED ZHEJIANG YUHONGWELL STEEL CO., LIMITED | ASTM A789/A789M, 2022 Edition, March 1, 2022 - Standard Specification for Seamless and Welded Fer... | |

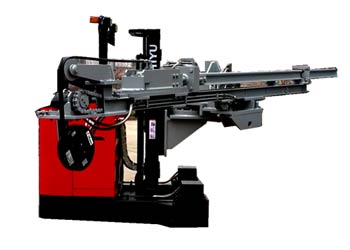

| Furnace Robotic Arm Machine | Seller: CITIC IC LUOYANG HEAVY MACHINERY CO., LTD | With the development of modern science and technology, industrial arm is a kind of high-tech auto... | |

| Horizontal Centrifuge Machine | Seller: CITIC IC LUOYANG HEAVY MACHINERY CO., LTD | TWZ series horizontal vibratory centrifuge belongs to the centrifugal dewatering machine, the ser... |