Sandwich Garage Door Panel Roll Forming Line

Processing flow chart

Sandwich garage door panel:

● Uncoiling→ Carrier platform → Embossing machine → Carrier platform → Hydraulic cutting → Carrier platform → Press square → Roll forming front panel.● Uncoiling→ Carrier platform → Embossing machine → Carrier platform → Hydraulic cutting → Carrier platform → Roll forming rear cover.

- Composite molding:

● Put the rear cover on the hydraulic foaming platform→ Gluing→ Put the Polystyrene panel on the rear cover → Gluing → Put the front panel on polystyrene panel → Compress → Heating → Get the sandwich garage door panel.

Single steel panel:

● Uncoiling→ Carrier platform → Embossing machine → Carrier platform → Hydraulic cutting → Carrier platform → Roll forming rear cover.

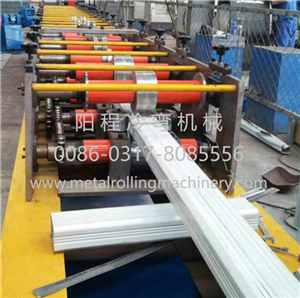

Front panel, rear cover & single steel sheet forming machine:

Technical parameter

|

Parameter |

Specification |

|

|

1 |

Processing material |

Galvanized steel sheet |

|

2 |

Processing thickness |

|

|

3 |

Voltage |

AC 380V 50Hz 3Phases or as per your request. |

|

4 |

Power |

|

|

5 |

Speed |

About 8-10m/min |

|

6 |

Roller station |

18 rows of rollers |

|

7 |

Weight |

About 4.7 tons |

|

8 |

Machine size |

About 4500mm*1300mm*1500mm |

Technical parameter

|

Parameter |

Specification |

|

|

1 |

Certification |

CE-BV / ISO / SGS |

|

2 |

Processing material |

Galvanized steel sheet |

|

3 |

Processing thickness |

|

|

4 |

Voltage |

AC 380V 50Hz 3Phases or as per your request. |

|

5 |

Power |

3kw |

|

6 |

Weight |

About 2.0 tons |

|

7 |

Machine size |

About 1500mm*1500mm*1500mm |

|

8 |

Screw |

Galvanized international standard |

150 tons of Press Machine

Technical parameter

|

Parameter |

Specification |

|

|

1 |

Certification |

CE-BV / ISO / SGS |

|

2 |

Processing material |

Galvanized steel sheet |

|

3 |

Processing thickness |

|

|

4 |

Voltage |

AC 380V 50Hz 3Phases or as per your request. |

|

5 |

Power |

|

|

6 |

Weight |

About 4.3 tons |

|

7 |

Machine size |

About 1000mm*800mm*2500mm |

|

8 |

Screw |

Galvanized international standard |

Technical parameter

|

Parameter |

Specification |

|

|

1 |

Certification |

CE-BV / ISO / SGS |

|

2 |

Voltage |

AC 380V 50Hz 3Phases or as per your request. |

|

3 |

Power |

8kw |

|

4 |

Weight |

About 0.8 tons |

|

5 |

Machine size |

About 6300mm*1000mm*3000mm |

|

6 |

Productivity |

About 3min/piece |

|

7 |

Screw |

Galvanized international standard |

SALES TERMS

1). Machine Price: Please contact us, we will try to give you good discount for starting our cooperation

2). Payment term: 30%TT should be paid as advance deposit, 70%TT before shipment

Or 100% LC at sight

3). Package: naked with simple plastic film and loaded in one 20-feet container

4). Delivery time: 50 working days after receipt of the deposit

5). Guarantee: 12 months. If any part of machine breaks, we will supply it for free.

6). After sales service

This is maintained free of charge for 12 months. When the machine is used in China, we will install and debug the machine for free; if it is used at abroad, we will send the professional technician to debug. Buyers should take all the fees for technicians traveling abroad, and pay 100USDdayperson.

Send product request

Other supplier products

| Downspout Roll Forming Machine Taking with Elbow Machine | We also can design the machine strictly according to above profile drawing. SURFACE TREATMENT 1). mainly consists of decoiler, roll forming syste... | |

| 1.25M-1.0MM Automatic Cutting Machine | SURFACE TREATMENT Raw material: colored steel sheet, galvanized sheet, aluminum sheet, TECHNOLOGY 7-ton hydraulic decoiler&r... | |

| YC 914-75 Steel Floor Deck Roll Forming Machine | Floor Decking Roll Forming Machine We also can design the according to your required profile SURFACE TREATMENT 1) Processing material: galvanize... | |

| YC 1250MM Embossing Machine | SURFACE TREATMENT (1) Processing material: galvanized steel sheet, aluminium sheet (2) Material thickness: 0.25-0.55mm (3) Feeding width: wi... | |

| Door Panel Forming Machine | SURFACE TREATMENT 1) Processing material: aluminium/zinc/galvanized steel/colored steel coil 2) Material thickness: 0.3-0.7mm 3) Effective width:... |