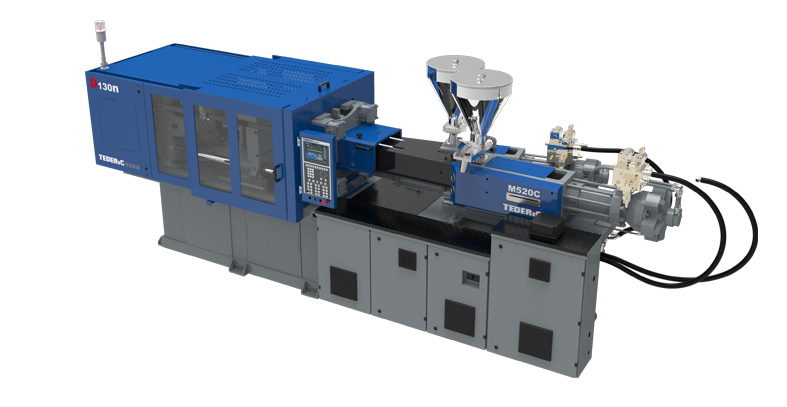

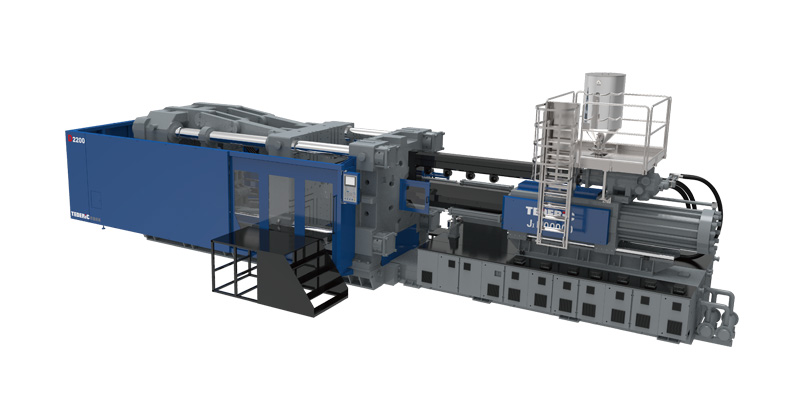

DH-i Two-platen Injection Molding Machine

Introduction

DH full hydraulic series injection molding machine is of two-platen, dual cylinder injection unit and clamping force from 480 – 7000 tons. Its modularized design, free match-up of clamping and injection units can cater to customer needs, and also reduce floor area occupation and costs. The super efficiency servo IMM is being energy saving and environmentally friendly, and configured with sensitive servo driving system to give quick response. With customizable super large mold thickness and opening stroke, the machine models are especially suitable for deep-cavity plastic products of sizable mold thickness demand.

Commonly injection molding machines are toggle type, also called toggle type injection molding machine, with a front, middle and back platen, but two-plateninjection unit of injection molding machinegoes by straight clamping, with only front and back platen. The mold opening force of two platen injection molding machine is comparatively large, which makes it easy to process products of deep cavity, big material volume and complex shape, with even higher mold clamping accuracy. Besides, two platen injection molding machine can realize the independent closed-loop control of high-pressure hydraulic clamping cylinders through the development of special structure and control software. In the global market, China's biggest injection moulding machinetechnology currently holds the lead position.

Design Highlights:

Extra Mold Thickness Clamping Force

Big Mold-bearing Capacity

Synchronous braking structure

Modularized Design

Clamping tie-bar piston structure

Feature:

High precision: quick response of clamping force, repeatability precision of molding opening position within ± 0.5 mm and of injection position within ± 0.5 mm.

Stable and energy-saving: leading servo dynamic system deployed, 30ms high response and save 30%~80% energy compared to the traditional hydraulic system

Flexible: can be applied to varying types of molds.

We have hydraulic clamping injection molding machinefor sale, If you need, please contact us in time.

Tederic Machinery Co., LTDoperates as an world-renowned plastic injection molding machine manufacturer and solutions provider. The company is renowned amongst customers for its excellent product performance , satisfactory technical support and after sales service.

Tederic Machinery co., LTD was founded in 2003, having two main factories in China currently,one is Tederic headquarters and one is tederic injection molding machinefactory, which are located in Hangzhou City and Huzhou City respectively. The total plant area are 120,000 square meters and the total number of employees is more than 800. We praise the concept of innovation and implements which by spirit of improving every day. After 16 years of continuous development and putting efforts, Tederic has become one of the top three enterprises in China's injection molding machine industry in terms of comprehensive strength. In 2017, Tederic machinery co., LTD was listed on the main board of the Shanghai stock exchange (SH603289), and it is also the first injection molding machine company listed on the main board of China.

Tederic Machinery Co., LTD operates as an world-renowned plastic injection molding machine manufacturer and solutions provider. We provide injection moulding machine, plastic moulding machine,tederic injection molding machineand etc. Want to know more? Please contact us.

Send product request

Other supplier products

| DD-MMc Multi-color (marble) Injection Molding Machine | Introduction DD-MMc mixed color series is an two colour injection moulding machinewith two injection units. The injection units are arranged in par... | |

| TEDERIC HORIZONTAL INJECTION MOULDING MACHINE | Adhering to the product innovation spirit of improving every day, Tederic IMM horizontal plastic injection moulding machinetakes lead for its techn... | |

| DT-i Servo Energy-saving Injection Molding Machine | Introduction DT-i servo energy saving injection molding machine is basically the High rigidity double elbow five hinge clamping mechanism, equipped... | |

| TEDERIC HORIZONTAL INJECTION MOULDING MACHINE | Adhering to the product innovation spirit of improving every day, Tederic IMM injection moulding machine takes lead for its technology and quality ... | |

| DT-JI Lower Pressure Special Injection Molding Machine | Introduction TEDERIC D-JI low pressure injection molding machinedeveloped by Tederic Company combines extrusion and injection technology to form a ... |