TESTING EQUIPMENT

MECHANICAL ENVIRONMENT RELIABILITY TEST EQUIPMENT

CME Technology Co., Ltd. is specializing in manufacturing shock and vibration testequipment for mechanical testing and simulation, environmental reliability testing, non-standard testing, our products including shock /bump test system, drop tester, hydraulic shakers, multi-DOF motion simulation table, centrifugal constant acceleration tester, packaging test machine...

The reliability test equipment meets a wide range of shock and vibration teststandards including MIL-STD-810G, MIL-STD-202, MIL-STD-750, MIL-STD-883, MIL-STD-901D, IEC60068-2, ISTA, ASTM, IEC68-2-27, UN38.3, UL2580, ISO 2248, ISO-2247……

Besides, CME has an excellent design team and R&D team, which provides non-standard customized solutions for reliability testing, as well as the laboratory setup consulting, capability of integrating planning, design, manufacturing, and installation and service as one.

MECHANICAL RELIABILITY TESTING MACHINE CME OFFERS

Shock/Bump Test Machine

KRD10 Hydraulic Vertical Shock Test System

KRD11 Pneumatic Vertical Shock Test Machine

KRD12 Pneumatic Horizontal Shock Test Machine

KRD13 High Energy Shock Test System

KRD16 High Impact Shock Test System

KRD17 Bidirectional Vertical Shock Test System

KRD20 Pneumatic Bump Test Machine

Shock/Bump Test Machine

SRS Test Equipment

Constant Acceleration Tester

Drop Test Machine

Transport Simulation Vibration Testing Machine

Multi-Axial Simulation Table

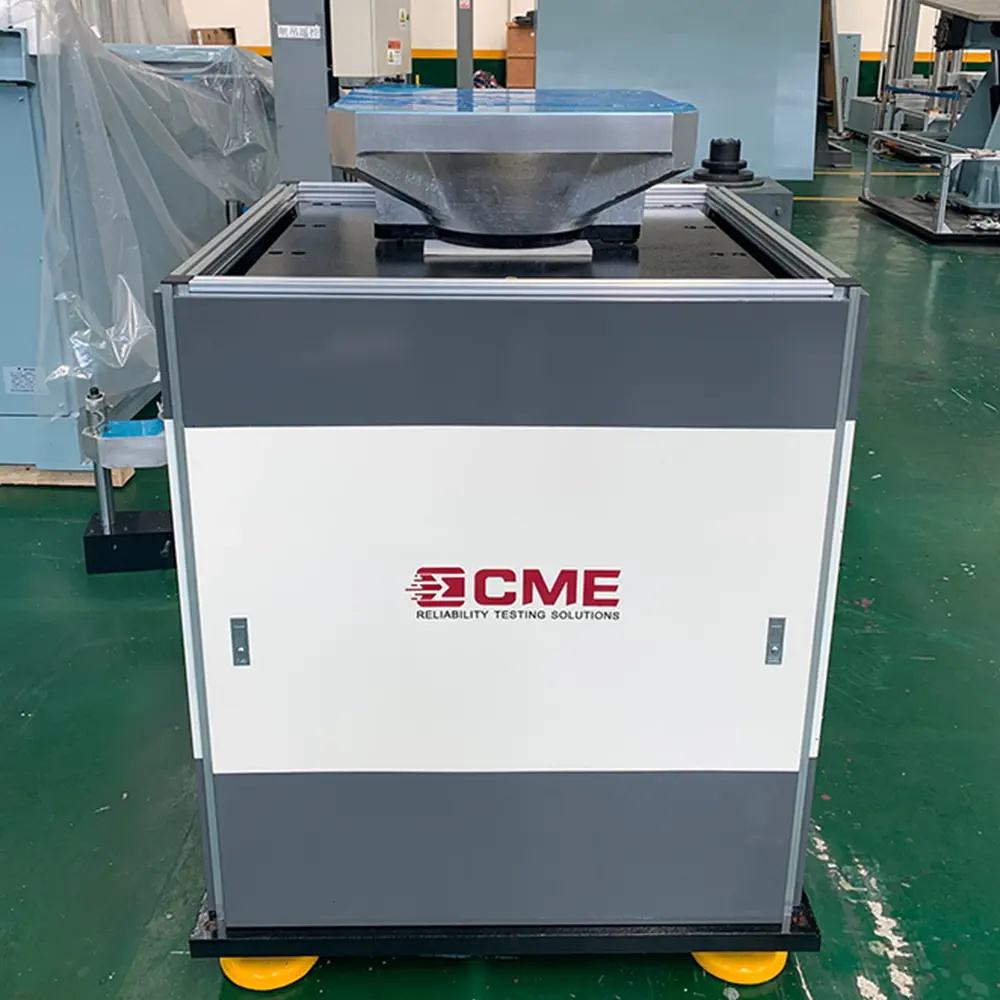

Vibration Shakers

Package Testing Equipment

Center of Gravity & Moment of Inertia Measurement

MECHANICAL ENVIRONMENT RELIABILITY TEST NUMBERING RULE

KRD XY-ZZ (KRD- CME; X— product type; Y— serial number; ZZ— load or force)

4— drop test; 5— transportation simulation;

6— multi-axial simulation table; 7— hydraulic shaker;

8— mechanical shaker; 9 —instrumentation;

10— packaging test; 20— mass centroid; 30— a moment of inertia

WHAT IS RELIABILITY TESTING?

The environmental reliability test is to verify the ability of the product to work normally when constantly subjected to the influence of itself and the external climate and mechanical environment during the design and application process.

Reliability testing is to verify the ability of the product under the specified environmental conditions. The reliability testing normally including following aspects: mechanical testing, environmental testing, lifetime testing, electrical testing. All these tests will be performed in laboratory, the purpose is to evaluate the product performance during the design and application process, in order to avoid the failure and improve the product’s integrity.

WHAT IS MECHANICAL RELIABILITY TESTING?

Mechanical reliability tests mainly include: vibration test, drop test, mechanical shock test, bump test, constant acceleration test, etc. Mechanical testing is essential for testing the electronic products under different mechanical stresses.

WHY IS RELIABILITY TEST SO IMPORTANT?

The reliability testing is to verify the reliability of the product or components during the R&D phase, trial production phase and sampling inspection phase, which is essential step for companies to save R&D cost and improve product performance and quality.

Mechanical testing is an integral part of any design and manufacturing process – and critical in aerospace. Its scope ranges from characterizing material properties to validating final products. Ensuring safety is its core mission, but testing also plays an important role in contributing to cost effective design, and technological evolution and superiority.

Send product request

Other supplier products

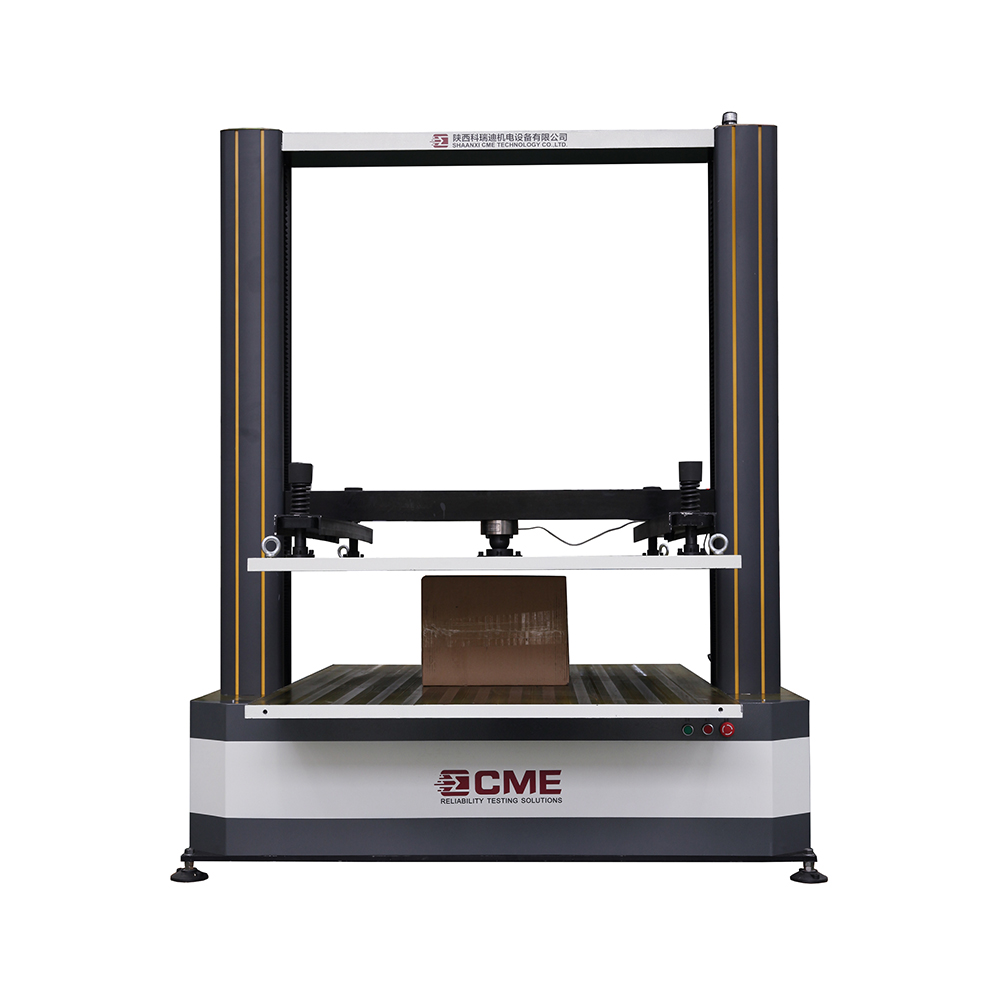

| KRD101 Packaging Compression Tester | KRD101 Packaging Compression Tester KRD101 series packaging compression testeris the ideal equipment for the compression strength test of various ... | |

| KRD100 Incline Impact Tester | KRD100series incline impact tester is a testing machine that evaluates the ability of loads to withstand inclined impacts or crushing forces due to... | |

| KRD200 Center of Gravity Measurement System | The center of gravity (CG) (or center of mass) of an object is the average location of the weight (or mass). It's a crucial mass property in the fi... | |

| WHAT IS SHOCK TEST? | Shock environment is a transient physical accelerating, such as impact, free-fall, kick, earthquake, or explosion. A shock pulse can be characte... | |

| KRD13 HIGH ENERGY SHOCK TEST SYSTEM | KRD13 series pneumatic high-energy shock test system is an automatic pneumatic lifting vertical pressure shock testing equipment. The high energy t... |