SHOT PEENING MACHINE

Shot peening machineis a process specifically designed to enhance the fatigue strength of components which are subject to high alternating stress. It can help to prevent fatigue cracks, corrosion, deteriorated strength and premature fatigue that can be caused by machining and form metal parts which also creates internal stress concentration. It also helps to prevent crack formation and growth since typically fatigue cracks generally begin at the imperfection on the surface of the material.

Application ofshot peening machine:

Crankshafts

Gear wheels

Connecting rods

Automotive gear parts

Coil springs

Turbine blade (Aircraft)

Airframe components

Suspension springs

Medical implants

Technical specification of shot peening machine

|

Items |

unit |

QGHP400 |

QGHP500-1 |

QGHP500-2 |

QGHP500-3 |

|

Max working size |

mm |

Φ400*600 |

Φ500*1100 |

Φ500*1100 |

Φ500*1100 |

|

Max loading weight |

kg |

200 |

500 |

500 |

500 |

|

Blast wheel quantity |

1 |

2 |

2 |

2 |

|

|

Number of chamber |

2 |

2 |

3 |

4 |

Advantages Of Shot Peening:

It reduces stress corrosion splitting

It can prepare components for plating

It straightens fragments that were deformed when manufactured

It reduces casting permeability

It can alter part dimensions

It will improve oil retention

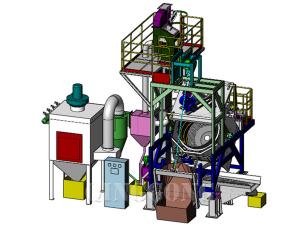

Transportation System:

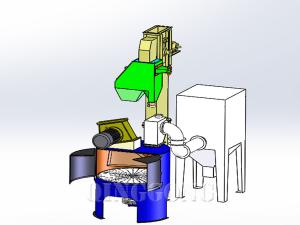

2-4 rotating carousel chambers allow one chamber to process (shot blasting or peening) while others to load and unload work-pieces. A higher production efficiency is insured.

Hanger with self rotating function keep work-pieces rotating while processing for a high abrasive coverage.

shot peening machine 8.jpg

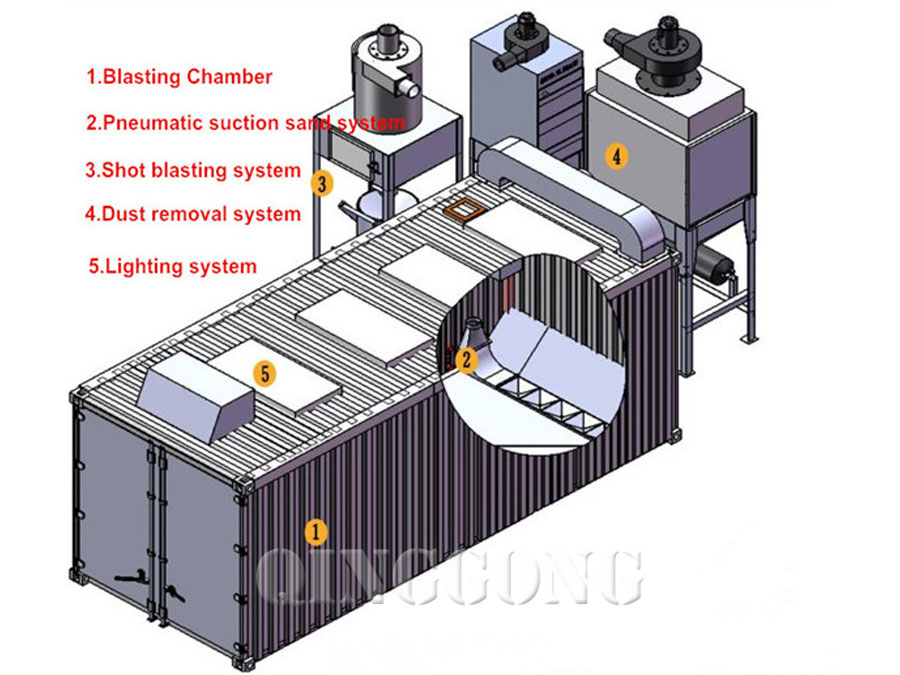

Blasting chamber:

The engineering team uses 3-D dynamic simulation design blast turbines layout to ensure that the steel shot ray can cover the surface of the workpiece 360 degrees.

Shot blasting chamber with Mn13 steel guard plate which has high impact toughness and high service life, fully realize the reflection funcation of abrasive and improve the cleaning quality. That we promise 10 years maintenance-free warranty to blasting chamber.

We can offer sorts of roller shot blasting machinefor sale, if you have needs to buy shot blasting machine, please contact us.

Send product request

Other supplier products

| FLOOR SHOT BLASTER | Floor shot blasteris a kind of shot blasting machine for concrete floors, steel plates. The floor shot blaster can clean up the floatation and imp... | |

| BARREL TYPE SHOT BLASTING MACHINE | The Barrel Blast Machine line provides outstanding performance and reliability. Designed for foundry, forge and heat treat requirements. The Barre... | |

| AIR BLAST ROOM | Air blast roomor Air blasting cabinet with pneumatic media reclaim system – An economical alternative, vacuum reclaim systems utilize cyclone... | |

| STEEL STRUCTURE SHOT BLASTING MACHINE | Steel shot blasting machineis the most environment-friendly option for corrosion removal and surface preparation on a steel structure. Steel shot b... | |

| ROTARY TABLE SHOT BLASTING MACHINE | Rotary shot blastermachineor table type shot blasting machineis suitable for various shapes and dimensions, casts, forged parts, pressed parts, ste... |