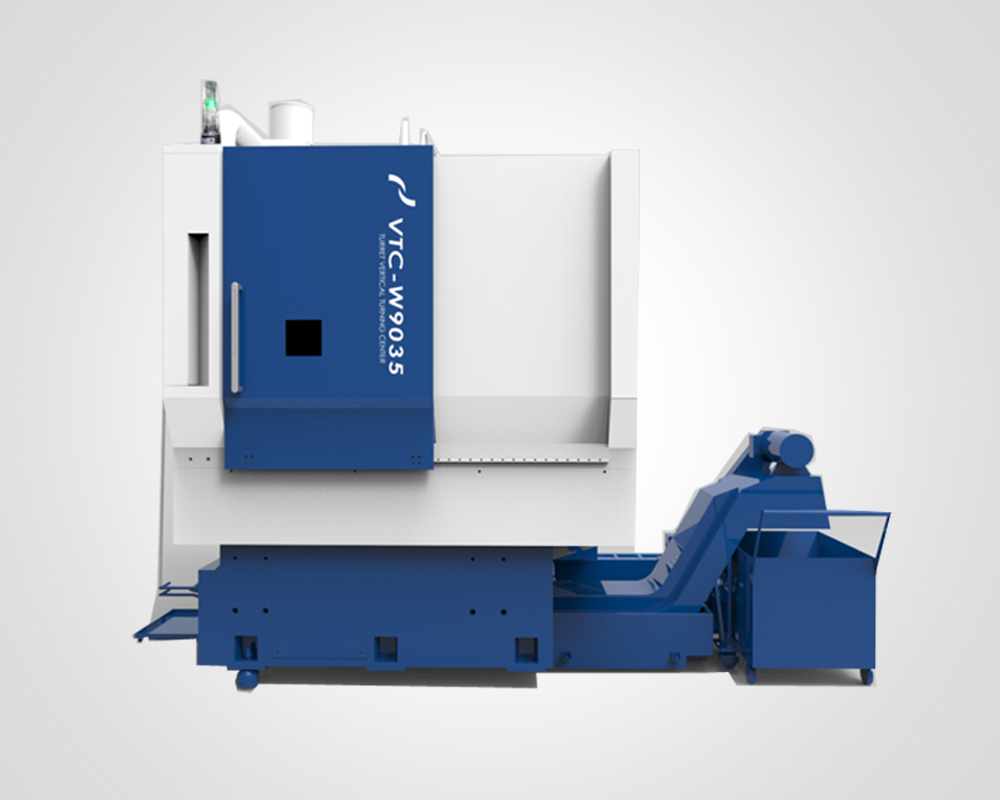

HBP Series Planer Type Milling and Boring Machine

The X/Y/Z servo axis adopts the servo motor direct connected precision planetary reducer to drive the large-diameter, high-precision double nut preloaded ball screw. The planer type horizontal boring and milling machine tool guide rail adopts the roller linear rolling guide rail pair. The X-axis and Z-axis of Deed CNC planer type milling machine adopt the three guide rail design to ensure the high bearing and high stability of the planer type CNC milling machine tool. We also provide cnc horizontal milling machine for sale. For custom planer type horizontal boring machine, Inquiry now.

HBP SERIES PLANER TYPE HORIZONTAL BORING AND MILLING MACHINE FEATURES

For Deed CNC HBP series planer type horizontal boring machine and type milling machine, X/Z axis adopts three imported heavy-duty roller linear guide rails, imported ball screw pair, fully closed telescopic shield, and fully closed-loop control. Two-speed reduction gearbox plus one-stage gear is adopted for deceleration, with the maximum speed of 2000, the maximum output torque of 2000Nm, the maximum reduction ratio of 1:14.46, and the minimum reduction ratio of 1:2.63. The spindle bearing adopts FAG special bearing, which is cooled and lubricated by thin oil circulation, so as to ensure the long-term and high-precision operation of the spindle.

HOW DOES HBP SERIES PLANER TYPE HORIZONTAL BORING AND MILLING MACHINE WORK?

This metal milling cnc machine is suitable for processing various kinds of basic large parts, plates, discs, shell parts, molds and other parts with large and medium size, large and medium weight. For Deed CNC HBP series planer type horizontal boring machine and type milling machine, After one-time workpiece clamping, a variety of processing such as milling, drilling, boring and reaming can be continuously completed with the characteristics of automatically, efficiently and accurately.

HBP SERIES PLANER TYPE HORIZONTAL BORING AND MILLING MACHINE WORKING PRINCIPLE

For Deed CNC HBP series planer type horizontal boring machine and type milling machine, The machine tool is column movable, with a single column, transverse base, and side hanging spindle box layout, and is equipped with a tool and workpiece cooling system, The transverse (x-axis) feeding movement of the cnc industrial machine tool is realized by the transverse movement of the worktable along the bed, the longitudinal (Z-axis) feeding movement of the machine tool is realized by the longitudinal movement of the spindle box and column along the longitudinal base, the vertical (Y-axis) movement of the machine tool is realized by the up and down movement of the spindle box along the column, and the longitudinal movement of the boring bar is realized by the movement of the boring bar in the spindle box sleeve (W-axis), the worktable can realize 360 ° continuous rotation of B coordinate on the sliding saddle (with four-point precise positioning function), the arbitrary indexing positioning function of the rotary table is realized through disc spring clamping and hydraulic loosening.

HBP SERIES PLANER TYPE HORIZONTAL BORING AND MILLING MACHINE SPECIFICATION

PBC1120 planer type horizontal boring machine and planer type milling machine

Model Unit PBC1120planer type horizontal boring machine and planer type milling machine

Boring spindle Diameter mm 110

Taper type BT50

Spindle motor kW 18.5/22.5

Max torque Nm 2000

Max speed rpm 2500

CNC rotary table Worktable m 1.2×1.4 1.6×1.8

Positioning accuracy " ±6 ±6

Repeatability " ±3 ±3

Load capacity Kg 8000 100000

Travel distance X-axis mm 2000

Y-axis mm 1600

Z-axis mm 1200

W axis mm 600

Feed speed Transverse (X) mm/min 2-6000

Vertical (Y) mm/min 2-6000

Longitudinal (Z) mm/min 2-6000

Axial (W) mm/min 2-2000

Rapid traverse Transverse (X) mm/min 10000

Vertical (Y) mm/min 10000

Longitudinal (Z) mm/min 10000

Axial (W) mm/min 3000

PBC1330/40 planer type horizontal boring machine and planer type milling machine

Model Unit PBC1330/40planer type horizontal boring machine and planer type milling machine

Boring spindle Diameter mm 130

Taper type BT50

Spindle motor kW 22/30

Max torque Nm 2000

Max speed rpm 2500

CNC rotary table Worktable m 1.8×2.0 2×2.2

Positioning accuracy " ±6 ±8

Repeatability " ±3 ±4

Load capacity Kg 25000 30000

Travel distance X-axis mm 3000 4000

Y-axis mm 2000

Z-axis mm 1600

W axis mm 800

Feed speed Transverse (X) mm/min 2-6000

Vertical (Y) mm/min 2-6000

Longitudinal (Z) mm/min 2-6000

Axial (W) mm/min 2-2000

Rapid traverse Transverse (X) mm/min 10000

Vertical (Y) mm/min 10000

Longitudinal (Z) mm/min 10000

Axial (W) mm/min 3000

Most Required CNC Machines

5 axis gantry type machining center

Horizontal boring and milling center

CNC drill tap machine

cnc horizontal turning center

Horizontal machining center with pallet changer

Planer type milling machine for manufacturing and machining

Deed CNC introduces a revolutionary planer-type milling machine, redefining precision manufacturing and machining. Engineered to excel in complex operations, this machine boasts exceptional rigidity and stability, ensuring unparalleled accuracy. Its planer-type structure enhances versatility, accommodating diverse workpieces with ease.

Equipped with advanced CNC technology, the planer type horizontal boring machine offers intuitive controls for streamlined programming and operation. Whether for intricate molds, large components, or intricate parts, Deed CNC's planer-type milling machine guarantees exceptional results. Its robust construction minimizes vibration, while high-end components ensure prolonged durability.

In the realm of modern manufacturing, precision is paramount. With Deed CNC's planer-type milling machine, intricate designs and intricate specifications are brought to life with utmost fidelity, solidifying it as the cornerstone of industries reliant on uncompromising accuracy and efficiency.

Send product request

Other supplier products

| VL-SERIES VERTICAL MACHINING CENTER | VL series vertical machining center is a small and medium-sized vertical machining center designed by Germany and made in China. It mainly aims at ... | |

| HBP SERIES PLANER TYPE HORIZONTAL BORING AND MILLING MACHINE | The X/Y/Z servo axis adopts the servo motor direct connected precision planetary reducer to drive the large-diameter, high-precision double nut pre... | |

| HB SERIES HORIZONTAL MILLING AND BORING MACHINE | HB Series is boring mills horizontal floor type:cnc horizontal borer. According to the different sizes, we have HB1116 and HB1316. We introduce Ger... | |

| Gantry CNC Milling Machine | PROVIDE PROFESSIONAL SOLUTIONS FOR DIFFERENT PROCESSING NEEDS New minerals and new materials Full stroke machining tool Model of efficient... | |

| UNIVERSAL HORIZONTAL LATHE | The machine tool adopts the mainstream oblique bed structure of Europe, America, and Japan, with integrated electromechanical, hydraulic, and gas d... |