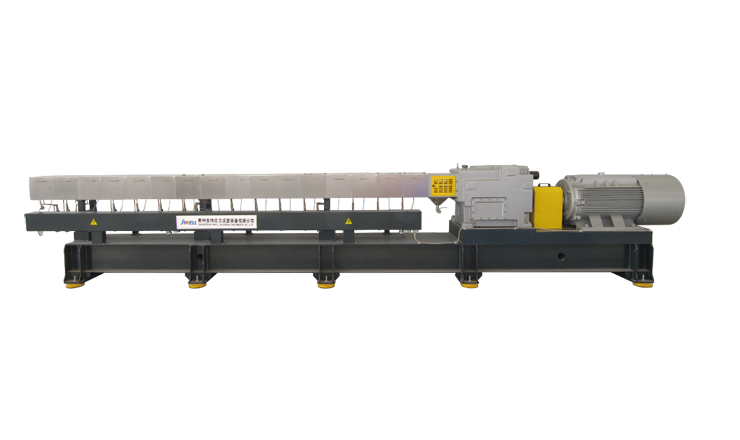

Plastic Compounding Machine

Plastic Compounding Machine

The twin-screw extruder is composed of a transmission device, a feeding device, a barrel, and a screw, and the functions of each component are similar to single-screw extruder. The difference from the single screw extruderis that there are two parallel screws in the twin-screw extruder.

The complex flow pattern of the material in the twin screw compounding machinemacroscopically shows the advantages that the single-screw extruder cannot match, for example, sufficient mixing, good heat transfer, large melting ability, strong exhaust ability and good temperature control of the material, etc.

Description About Plastic Compounding Machine

|

Item |

Description |

|

Place of origin |

China |

|

Brand name |

JWELL |

|

Model number |

CJWH-85 |

|

Capacity |

300-500kg/hr |

|

Typical application |

TPU |

|

Packaging details |

Wooden pallet packing |

|

Delivery time |

90days |

|

Payment terms |

Specifications of Plastic Compounder Machine

|

Model |

Diameter |

L/D |

Screw speed |

Motor Power |

Torque per shaft |

Specific torque |

Capacity Range |

|

mm |

rpm/min |

KW |

T/A3 |

kg/hr |

|||

|

CJWH35 |

24~68 |

600 |

30 |

235 |

75~150 |

||

|

1000 |

45 |

110~220 |

|||||

|

CJWH40 |

24~68 |

600 |

45 |

357 |

110~220 |

||

|

1000 |

75 |

190~380 |

|||||

|

CJWH52 |

24~68 |

600 |

90 |

692 |

220~440 |

||

|

900 |

132 |

330~660 |

|||||

|

CJWH65 |

24~68 |

600 |

160 |

1224 |

400~800 |

||

|

900 |

220 |

550~1100 |

|||||

|

CJWH75 |

71 |

24~68 |

600 |

220 |

1880 |

550~1100 |

|

|

800 |

315 |

800~1600 |

|||||

|

CJWH85 |

81 |

24~68 |

600 |

315 |

2713 |

800~1600 |

|

|

800 |

450 |

1100~2200 |

|||||

|

CJWH95 |

93 |

24~68 |

600 |

500 |

4131 |

1250~2500 |

|

|

700 |

600 |

1500~3000 |

|||||

|

CJWH110 |

108 |

24~68 |

500 |

630 |

6346 |

1500~3000 |

|

|

600 |

800 |

2000~4000 |

|||||

|

CJWH120 |

120 |

24~68 |

500 |

900 |

8705 |

2250~4500 |

|

|

600 |

1000 |

2500~5000 |

|||||

|

CJWH135 |

132 |

24~68 |

400 |

900 |

11586 |

2250~4500 |

|

|

500 |

1000 |

3000~6000 |

Plastic Compounding Machine Application

Petrochemical Powder Pelletizing and Powder Compouding:

Petrochemical powder pelletization and powder modification are one of the most important applications for twin screw extrusion machine. Through continuous efforts, optimization, and improvement, the integration of industry resources has been widely recognized by the market.

Bio-degradable Plastic Compouding and Pelletizing Series:

Typical application as plastic alloy, starch filled compound, bio-mass filled compound or mineral power filled compound for bio degradable plastics as PLA, PBAT, PBS, PPC, PCL, TPS, and PHA, etc.

Plastic Compounding Machine Performance and Advantages

The screw and barrel adopt the "building block" structure, which has good interchangeability, and can be used in any combination according to the different material processing technology;

The cylinder body is made of nitrided steel and bimetal materials, which are wear-resistant and corrosion-resistant, and extend the service life; the threaded elements are made of nitrided steel and high-speed steel. Normal tooth surface clearance, and good self-cleaning;

The specially designed connection method and transmission device enhance the strength of the threaded element and the mandrel. The above measures achieve the purpose of uniform material dispersion, good mixing and plasticizing effect, short material retention time, and high conveying efficiency.

JWELL Extrusion MachineryCo. Ltd is a high-tech manufacturer specializing in the research and development of yarn spinning machines, plastic extrusion lines. JWELL Extruder factory China has high qualified R&D and experienced mechanical and electrical engineer team.

Send product request

Other supplier products

| Film Extrusion Line | Film extrusion production line is a kind of screw plastic extruder. The working mechanism of plastic film extrusion machineis to fully plasticize t... | |

| PVC/TPU/TPV/TPE Sealing Profile Extrusion Line | TPE/TPU/TPV/PVC profile extrusionmachine is used for producing sealing strip of PVC, TPU, TPE, etc material, features high output, steady extrusion... | |

| HDPE Pipe Extrusion Machine | HDPEextrusion machineproduction line adopts the most advanced technology of Europe, It is a new research achievement of energy-saving production li... | |

| Pipe Extrusion Machine | JWELL Machineryis designed and developed in a new idea, pipe and profile extrusionline produces PP pipe series, PVC pipeline series, ABS pipeline s... | |

| Extrusion Line | Here, you can learn about various JWELL extruder chinaand related components of extrusion line machines, such as sheet extrusion line, plate extrus... |