FLOOR SHOT BLASTER

Floor shotblaster is a kind of shot blasting machine for concrete floors, steel plates.

The bead blaster floor machinecan clean up the floatation and impurities on the surface of the concrete at one time. It can also roughen the surface of the concrete road to make it uniform and rough, which will greatly enhance the adhesion strength of the waterproof layer and concrete base. So that the waterproof layer and bridge deck can combine much better.

We have floor shot blasting equipmentfor sale.

Overview of QINGGONG Floor Shot Blasting Equipment

The floor shot blasting machine is the most economical and efficient mobile small shot blasting machine.

Provide one-step surface preparation for a variety of concrete surface, steel plate, iron bridge, airport applications where a minimum amount of material or rust must be removed in preparation for resurfacing. Blast media (steel shot) is directed in a controlled pattern to scour the surface.

Floor Shot Blaster Basic Specification

|

Model |

QGLM200 |

QGLM250 |

QGLM550 |

QGLM800 |

|

Power (kw) |

14 |

18 |

29 |

38 |

|

Effective cleaning width(mm) |

200 |

250 |

550 |

800 |

|

Productivity on concrete (m²/h) |

80 |

120 |

300 |

450 |

|

Travel speed(m/min) |

||||

|

Dust collection type |

DC-1300 |

DC-1300 |

DC-1330 |

DC1330 |

Floor Blasting Machine Applications

Perfect for industrial floors, warehouses, factories roads and bridges, and supermarkets, the QINGGONG MachineryQGLM-250 concrete sandblasting machine is an environmentally sound choice for any surface preparation contractor.

Whether improving traction and skid resistance or prepping for coatings and overlays, the versatile QGLM-550 strips clean and profiles concrete and asphalt, or horizontal steel surfaces in one easy step.

QGLM800 floor concrete sandblasting machineis suitable for industrial plant and warehouse floors, parking garages, ship decks, highway or bridgework, airport runways, and other large jobs.

QGLM 200 floor blasting equipment is an ideal for industrial floors, warehouses, commercial or residential garage floors, this shot blaster can prepare up to 450 to 600 sq. ft. per hour. The QGLM-200 floor shot blaster machine is also perfect as a complementary unit for larger shot blasters.

Floor Blasting Machine Manufacturing Operation

Floor Shot Blaster Working Principle

Floor shot blaster is driven by the motor to produce centrifugal force and wind force in high-speed rotation. Operators need to input a certain particle size of shot material that the flow can be controlled. As soon as the shot material is fed into the pellet tube of the shot blasting floor equipment, it will be accelerated into the pellet wheel at high speed. Under the action of the centrifugal force, the shot material is thrown into the directional sleeve by the window of the dividing wheel, then it will be thrown through the directional window which can control the throwing direction of the projectile material. The high-speed rotating blade of the bead blaster floor machine will pick them up and accelerates along the length direction of the blade until they are thrown out. The thrown projectiles can form a certain fan-shaped stream beam which can impact the working surface and play the role of clearing and strengthening.

The shot material, dust, and impurities go through the bounce chamber to the top of the hopper. The high-power duct collector can separate the pellet and dust through the separation device above the hopper with the pellet enters the hopper for cycling and the dust enters the dust collector through the connecting pipe. When the dust enters the dust collector designed for concrete blasting machine, it is separated by the filter core and stays in the ash hopper and the surface of the filter core. The automatic backflow deduster can clean each filter element automatically at intervals through the backflow air provided by the compressor. The equipped vacuum cleaner can recover the shot material and impurities after cleaning and the shot material can be used again. The floor shot blaster equipped with a dust remover can achieve the construction of dust-free and pollution-free, which can not only improve the working efficiency but also protect the environment.

Benefits and Features of Floor Shot Blaster for Sale

Simple operation, one person can operate the machine

Easily maneuverable, self-propelled machine–forward and reverse AC inverted drive-motor with integrated brake for even, down slope operation on ramps and inclines

The dust collector is connected with chamber by hose to realize dust-free operation

If you want to know more kinds of steel plate shot blasting and painting line, please visit our website.

Send product request

Other supplier products

| STEEL PLATE SHOT BLASTING MACHINE | Steel plate shot blasting machine is one kind of roller conveyor shot blasting machines. It can remove all rust, corrosion and mill scale from stee... | |

| OVERHEAD RAIL SHOT BLASTING MACHINE | Overhead conveyor shot blasting machineallows the workpieces to move with constant speed through the machine. The conveyor consists of a chain and... | |

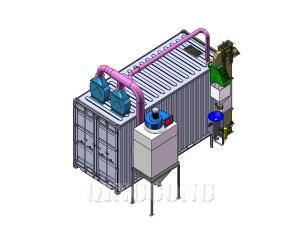

| CONTAINER BLASTING ROOM | When factory space is at a premium or a temporary site is to be utilized our blasting containers provide an instant and economical solution. Shot b... | |

| PRESERVATION LINES Free Quote | On the preservation line, sheets and profiles are thoroughly blast cleaned and provided with a temporary corrosion protection coating. Along with... | |

| GAS CYLINDER SHOT BLASTING MACHINE | Gas cylinder shot blasting machine is used to automatically clean the surface of the cylinders by blasting of the abrasive coming from the blast tu... |