Magnetic Flux Leakage Testing Equipment

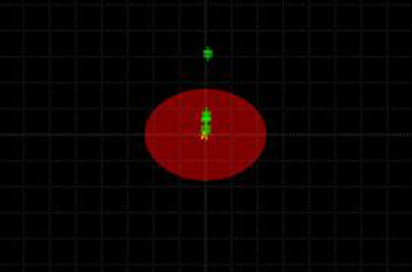

Electromagnetic detection is a very important non-destructive testing method and is widely used. Magnetic flux leakage is a magnetic method of nondestructive testing that is used to detect corrosion and pitting in steel structures, most commonly pipelines and storage tanks. The basic principle is that a powerful magnet is used to magnetize the steel. When used in combination with other methods, it provides a quick and inexpensive assessment of the workpiece of ferromagnetic materials. With the advancement of technology, people are paying more and more attention to the automation of the inspection process. This not only reduces the labor intensity of the inspection work but also improves the reliability of the test results and reduces the influence of human factors. The MFI magnetic flux leakage inspection method is a highly automated magnetic detection technology. The principle is that after the ferromagnetic material is magnetized, the surface and near-surface defects form a leakage magnetic field on the surface of the material, and defects are detected by detecting the leakage magnetic field. In this sense, the magnetic particle detection technology commonly used in pressure vessel inspection. However, it is customary to use the method of measuring the leakage flux with a sensor as the magnetic flux leakage detection, and the magnetic flux to detect the leakage flux. The method is called magnetic particle detection and they are juxtaposed into two detection methods.

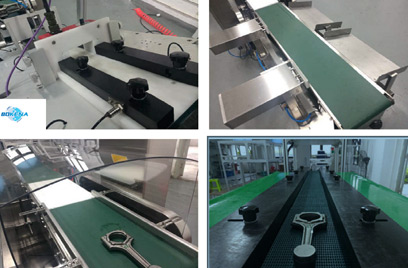

Magnetic flux leakage testing equipmentcan only detect surface and near-surface crack defects, and it needs surface grinding when testing. It is only suitable for the detection of workpiece discontinuation. In addition to the surface and near-surface crack defects, the MFI magnetic flux leakage inspection can also find the corrosion inside the workpiece from the outside. Defects such as pits, and do not need to be polished on the surface of the workpiece, suitable for on-line inspection of workpieces. On-line inspection of workpieces is currently the most urgent method for users, which can reduce unnecessary parking and reduce inspection costs. In addition, the magnetic flux leakage detection can also quantify the depth and length of defects. Although the application of magnetic flux leakage detection technology is rarely used in workpiece inspection, it has the advantages that magnetic particle detection does not have, so its application prospect is very broad.

BKNis an eddy current testing benchmark enterprise and has long been committed to the development and production of bearing hardness and crack eddy current screening equipment. If you want to know more details or want a quotation, just feel free to contact us!

Send product request

Other supplier products

| Bolt Eddy Current Sorter BKNFX-11 | Bolt: Mechanical parts, cylindrical threaded fasteners with nuts. A type of fastener consisting of a head and a screw (a cylinder with an external... | |

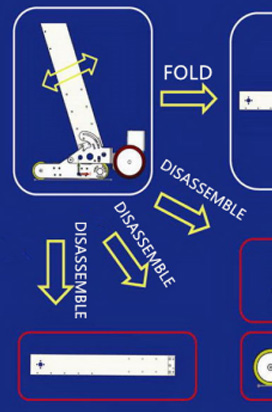

| MFL101 Tank Floor MFL Scanner | Technical Characteristics of MFL101 mfl tank floor inspection The mfl tank floor scannerhas a unique full modular structure, from the main body of... | |

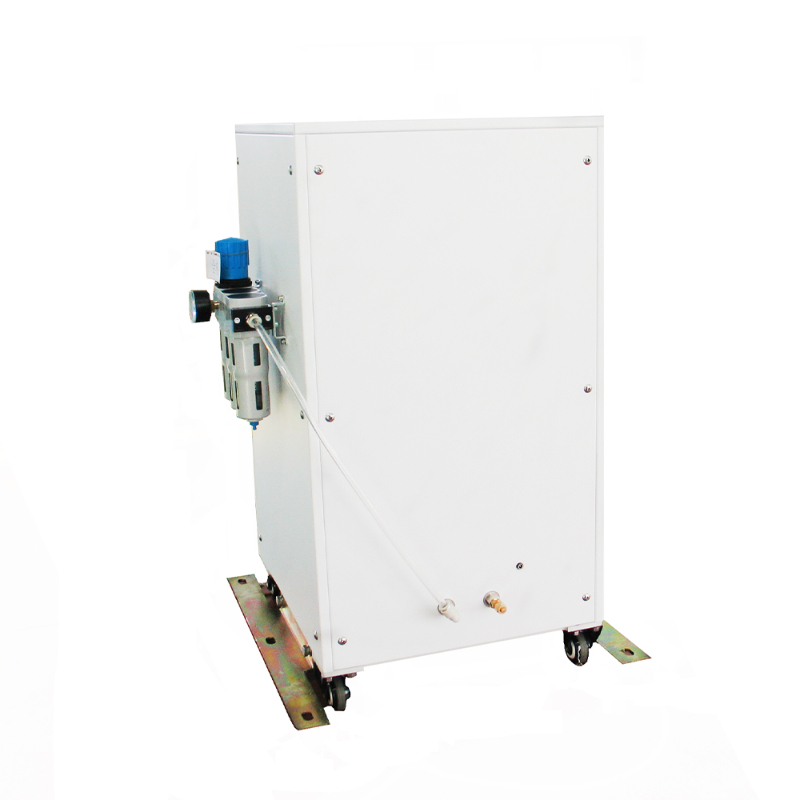

| Portable Magnetic Flux Leakage Testing Equipment | Magnetic flux leakage test refers to the formation of a leakage magnetic field on the surface of a test piece after it is magnetized due to defects... | |

| BKNET-0102 Welded Pipe Eddy Current Flaw Detector | The technology of BKN originated from eddy current Laboratory of Institute of Materials, Nanjing University of Technology. At present, it is a lead... | |

| Eddy Current Testing Equipment | ECT Eddy current testingis a non-contact testing method, which mainly uses the electromagnetic field and electromagnetic induction between metals t... |

Same products

| Lost Wax Casting Y Piece FlowSplit Fitting | Seller: Qingtian Baoli Casting Co., Ltd. | Lost Wax Casting Y Piece FlowSplit Fittingis produced through the lost wax casting method, enabli... | |

| Mini Nitrogen Generator | Seller: Shandong benyuan international trading co,.ltd. | Mini Nitrogen Generator Mini Nitrogen Generator Are you looking for a reliable, cost-effe... | |

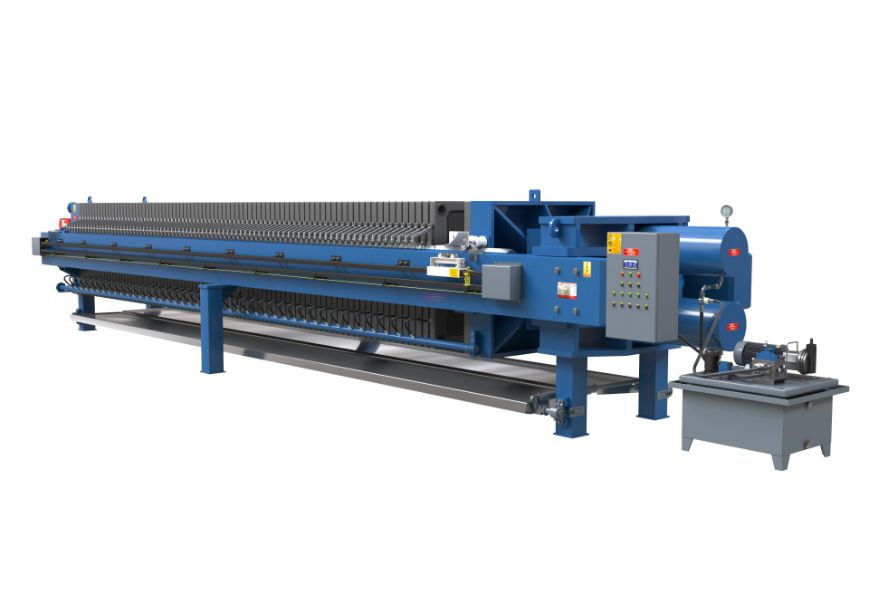

| filter press in chemical industry | Seller: ZHONG DA BRIGHT FILTER PRESS CO., LTD. | Our for Chemical Industry is designed to meet strict safety and environmental standards, en... | |

| Laser Cutting Service China METAL FINISHING | Seller: Dalian Zhuosheng Technology Co., Ltd | Laser Cutting Service ChinaMETAL FINISHING Laser Cutting Service ChinaMETAL FINISHING-China Dal... | |

| Intake Manifold in Car Engine | Seller: SDZ AUTO PARTS CO.,LTD | The car intake manifoldis a component of an automobile engine that supplies a mixture of air to d... |