SURFACE FINISHING

The surface texture treatment requirements of special industries are extremely stringent, such as parts and products in extreme climatic environment having a level of product surface cleanliness, types of primers, topcoats, and protective coatings. Richconn, as a professional surface finishing supplier, has a complete surface treatment plant. Metals can be sprayed with tungsten carbide, zirconia, alumina, nitriding, carburizing, electrophoresis, vacuum coating (PVD), nickel plating, galvanizing, chromium plating, sandblasting, anodizing, Teflon spraying, fingerprint protection coating, etc.

Surface Finishing SystemsTypes

- galvanized steel surface finishis to make the material have better performance and appearance.

CNC MACHINING CUSTOMTYPES

Anodizing

The anodization process is generally understood as energized anodization, which makes the current anode pass through gold.In the genus, the oxide solution acts as a cathode, so that the metal surface elements produce chemical reactions to form a certain thickness.

Polishing

Polishing broadly refers to the use of metal, non-metal, chemical, electrical and other media to contact on the rough surface, and make the surface flat and smooth through friction to achieve the effect of removing concave convex particles.

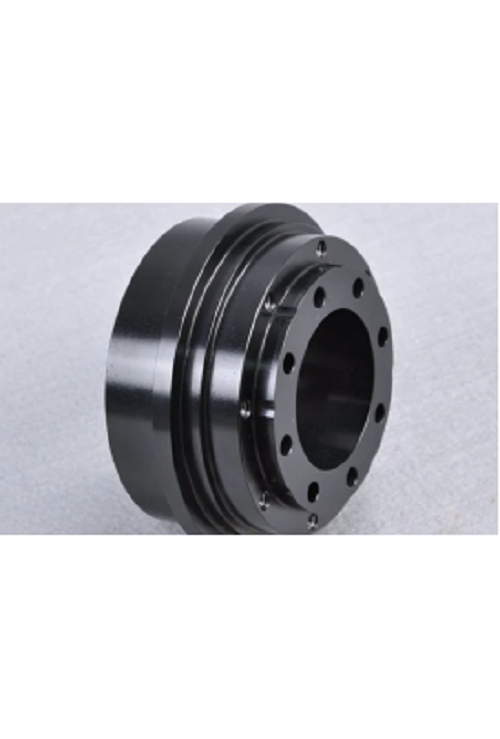

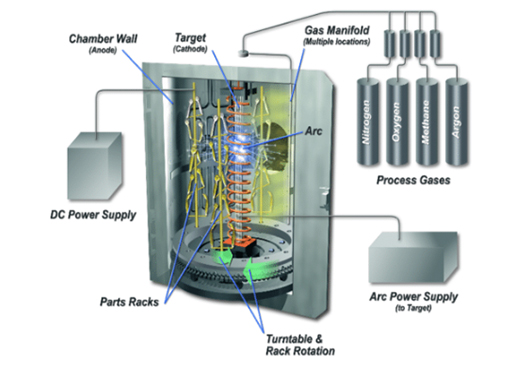

PVD Coating

PVD (physical vapor deposition) refers to physical vapor deposition. The process is divided into vacuum evaporation coating, vacuum sputtering coating and vacuum ion coating.

Powder Coating

Painting and Powder Coating are two common metal surface treatment processes.

Plating

The plating process is similar to the anodizing process, but the difference is that the plating of parts is a metal element, and anodizing only forms an oxide film on the metal surface.

Electrophoresis Coating

Electrophoresis: electrophoresis can be divided into anode electrophoresis and cathode electrophoresis. Now it generally refers to cathode electrophoresis.

Blackening Coating

Blackening: blackening, commonly known as metal bluing, is a metal surface treatment process.

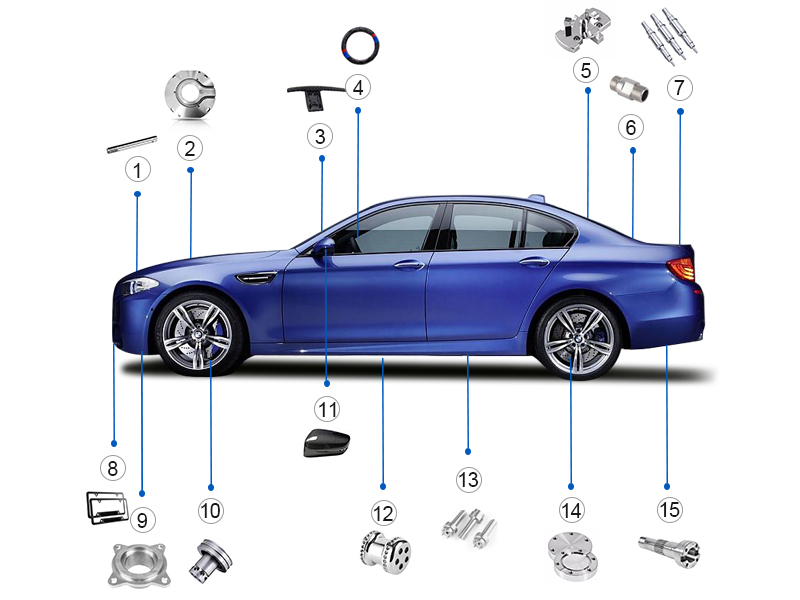

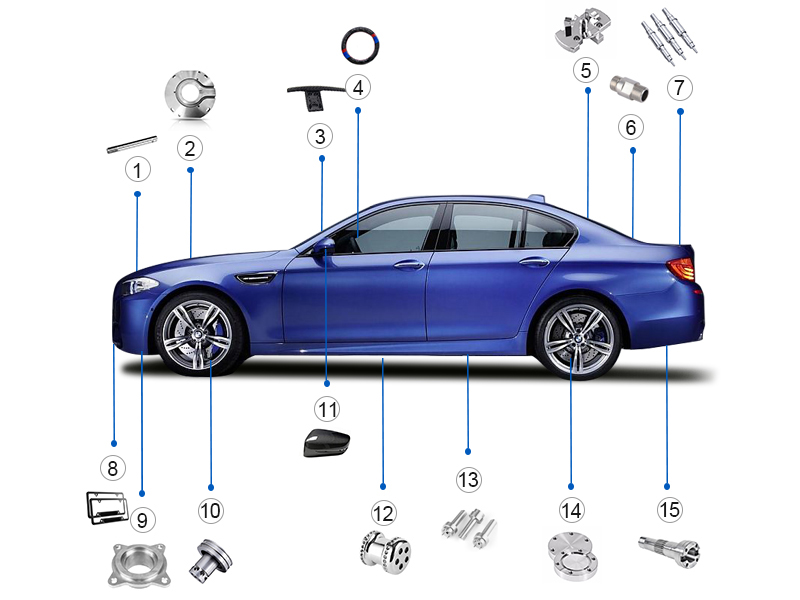

CNC SURFACE FINISH TREATMENT APPLICATION

CNC SURFACE FINISH TREATMENT ADVANTAGES

- nose radius and surface finishmakes the material or product have better performance and appearance, such as the PVD vacuum coating of the iPhone shell and glass, so that the glass is more wear-resistant and beautiful, and the middle frame is not easy to scratch and fall off the paint;

How to Choose the Right Surface Finishing Types?

Every surface finishing has its advantages and disadvantages, so choosing the right CNC surface finish depends on what features match your part requirements and application.

It’s essential to evaluate the functional and aesthetic characteristics of CNC finishes and coatings you need, and to consider how your part will interact with adjoining components. Whether or not your part will be subject to repeated or intense friction may sway your decision.

Also, remember to take into account your part operational environment. You may believe your part doesn’t need robust resistances, but the environmental facts might require a more intensive surface finish than you previously thought during the design phase.

CNC Machining Materials

CNC PLASTIC MACHINING

The machines used in CNC plastic machining are milling machines with 3/4/5 axes with digital control. The multi axis machining are automated and controlled by a computer that determines the path of the cutter according to the 3D file to be created.

CNC METAL MACHINING

Before our processing and production, through the optimization design of our engineers and the use of a variety of tooling fixtures, the production cost and processing time of our OEM precision cnc machining will be reduced. The machines we use are mainly 3-axis, 4-axis, and 5-axis CNC machining centers. In Shenzhen, we can easily purchase all kinds of high-quality metal materials in CNC manufacturing companies, which are controlled by computer programs based on three-dimensional file control graphics.

CNC MACHINING FOR SPECIAL MATERIALS

As a professional CNC machining parts company, Richconn provides OEM CNC machining services for ceramics, carbon fiber, titanium alloy, tungsten steel, and other special materials.

Send product request

Other supplier products

| Black Oxide Services | At Richconn, we rely on rack and suspend technology to provide black oxide coating services that are delivered quickly and meet high quality standa... | |

| PVD COATING | PVD COATING Physical vapour deposition, just ar PVD coating, as we usually call it, refers to vacuum ion plating and vacuum sputter plating; Gener... | |

| AUTOMOTIVE CNC MACHINING | We provide OEM / ODM incremental services and supporting services for customers to grow together according to the customer characteristics of the a... | |

| ANODIZING | ※ Source Manufacturer The Richconn was established in 2009 and is a professional precision anodizing company. ※ Mature Technology Complex and ... | |

| AUTOMOTIVE CNC MACHINING | We provide OEM / ODM incremental services and supporting services for customers to grow together according to the customer characteristics of the a... |

Same products

| Lost Wax Casting Y Piece FlowSplit Fitting | Seller: Qingtian Baoli Casting Co., Ltd. | Lost Wax Casting Y Piece FlowSplit Fittingis produced through the lost wax casting method, enabli... | |

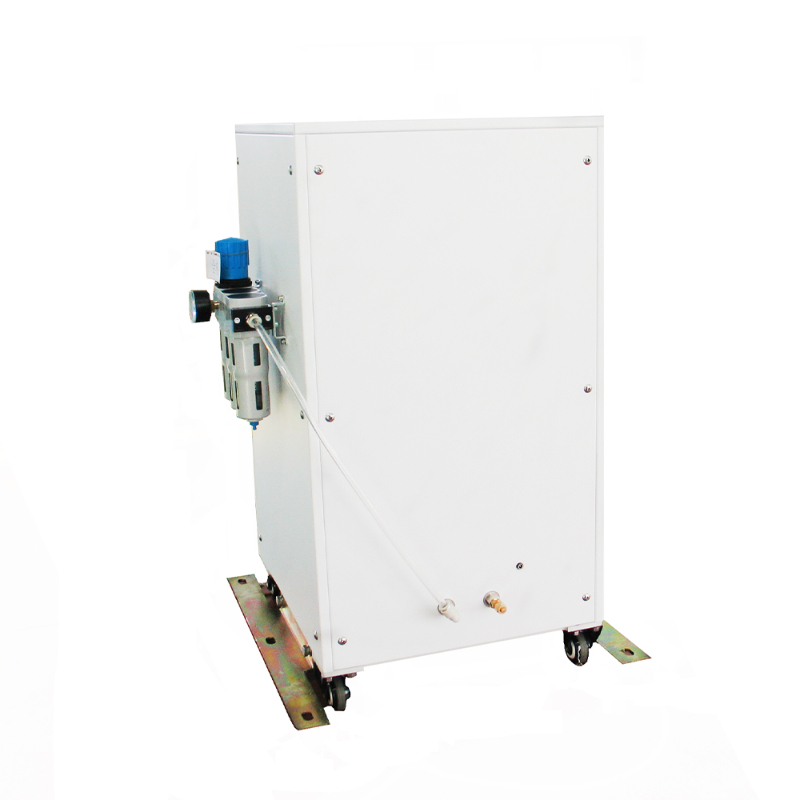

| Mini Nitrogen Generator | Seller: Shandong benyuan international trading co,.ltd. | Mini Nitrogen Generator Mini Nitrogen Generator Are you looking for a reliable, cost-effe... | |

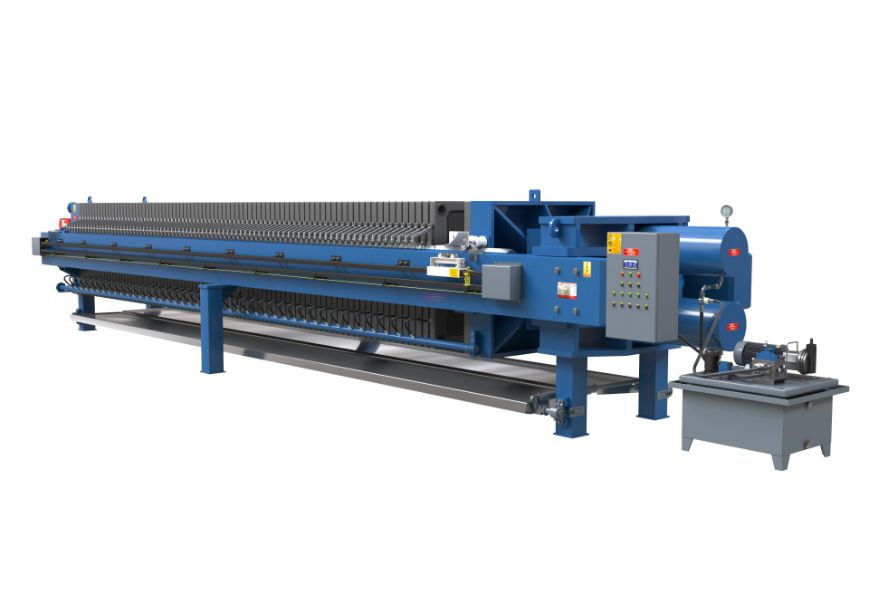

| filter press in chemical industry | Seller: ZHONG DA BRIGHT FILTER PRESS CO., LTD. | Our for Chemical Industry is designed to meet strict safety and environmental standards, en... | |

| Laser Cutting Service China METAL FINISHING | Seller: Dalian Zhuosheng Technology Co., Ltd | Laser Cutting Service ChinaMETAL FINISHING Laser Cutting Service ChinaMETAL FINISHING-China Dal... | |

| Intake Manifold in Car Engine | Seller: SDZ AUTO PARTS CO.,LTD | The car intake manifoldis a component of an automobile engine that supplies a mixture of air to d... |