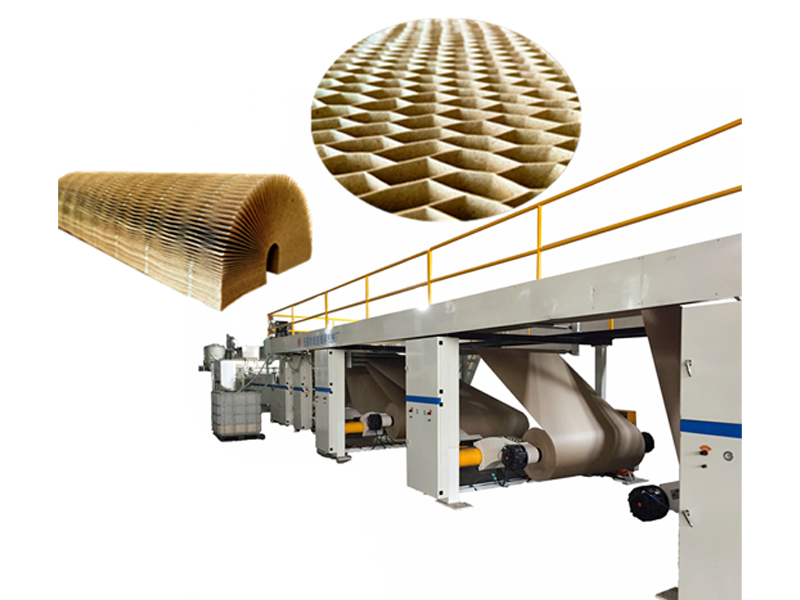

Paper Slip Sheet Machine

Paper Slip Sheet Machine is to produce slip sheets/flat paper boards with a thickness of Max.5mm and a width of Max.1200mm. It adopts an electric control system to guarantee a stable speed of 20m/min. The paper slip sheet machine has a drying system to dry the cardboard. The whole production includes paper stand, gluing part, pressing and forming, heating part, cutting part, and collecting. The slip sheet is made of imported high-strength kraft paper. The paper slip sheet machinehas good smoothness, moisture resistance, and tear resistance. It is an ideal replacement product for wood, paper, and plastic pallets. A lightweight, small-size, recyclable paper slip sheet machine can effectively save freight and reduce storage space. Slip board transportation and warehousing can be carried out without pallets. It is very suitable for container shipping, truck transportation workers, and goods turnover in warehouses. It is widely used in various product fields and transportation fields.

Lightweight, less materials, and low cost. Compared with other board structures, this structure of paper slip sheet machine has a better performance/price ratio of finished products, which is the key to the success of the paperboard.

High strength, smooth surface and not easy to deform. The structural stability is good, and it is not easy to deform. Paper slip sheet machine's outstanding compressive resistance and bending resistance are important characteristics required by box packaging materials.

Good impact resistance and cushioning. The paperboard is made of flexible paper core and facial paper, which has good toughness and resilience. The unique structure of paper slip sheet machine provides excellent cushioning performance and has higher energy absorption per unit volume among all cushioning materials. The high-thickness paperboard can replace the EPS plastic foam cushion that has been widely used.

If you want to know types of kraft paper slitting machine, please visit our website.

As the paper cutting machine manufacturer, SAN Machinerywas established in 2005 and has become China's best supplier for paper edge protector machines and paper honeycomb machines, as well as honeycomb paper cutting machine.

Send product request

Other supplier products

| Honeycomb Paperboard Machine | The honeycomb paperboard machineis composed of two parts Honeycomb Paper Core Machine and Honeycomb Paper Lamination Machine. This honeycomb paper ... | |

| Three-Purpose Paper Angle Board Machine | SANPPL-120DL is a regular machine, by changing molds, SANPPL-120DLU and SANPPL-120DLF can produce 2 and 3 types of protectors by changing the posit... | |

| EDGE BOARD MACHINE APPLIED FOR BOXES | Honeycomb carton box, honeycomb boxes are made of honeycomb cardboard by stamping, cutting and pasting. Paper edge protector is pasted at the inter... | |

| Honeycomb Paper Core Machine | The honeycomb paper core machineincludes 2 models. There are 7 parts: Heavy load hydraulic paper stand, Paper core gluing machine, Paper core conve... | |

| Paper Edge Protector Cutter | This catalog includes the post-processing machines of the paper edge protector. They are paper edge protector recutter and paper edge protector die... |

Same products

| 12V 250AH Gel Battery for Solar system | Seller: Shenzhen Changing Technology Co., Ltd | 12V 250AH Gel Battery for Solar system The 12V 250Ah Gel Batteryis a high-performance, maintenan... | |

| 39/52/65kW 61.44kWh Small-Scale C&L Energy Storage System | Seller: Shenzhen Changing Technology Co., Ltd | 39/52/65kW 61.44kWh Small-Scale C&L Energy Storage System ICHES-B is a high-voltage energy s... | |

| 24V 60Ah Lithium-ion Battery for Golf Cart | Seller: Shenzhen Changing Technology Co., Ltd | 24V 60Ah Lithium-ion Battery for Golf Cart The UT-GC2 Series 24V 60Ah Golf Cart Lithium-ion Batt... | |

| The 332.8V 10kWh (Single Phase) | Seller: Shenzhen Changing Technology Co., Ltd | The 332.8V 10kWh (Single Phase) Residential Energy Storage Systemis a high-capacity, premium-grad... | |

| 220/230/240V 5kWh - Residential Energy Storage System | Seller: Shenzhen Changing Technology Co., Ltd | 220/230/240V 5kWh - Residential Energy Storage System The 220/230/240V 5kWh Residential Energy S... |