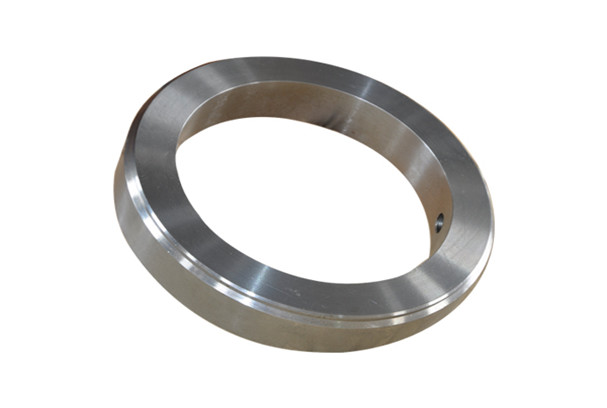

Die Casting

As a professional aluminum die casting co inc,ETCN provides our clients qualified die casting service. The product uses aninjection die castingprocess to complete the blank, cnc machining and manufacturingand polishing treatment, suitable for auto parts. In addition, die-casting service includes different types of materials such as zinc pressure die casting, aluminum pressure die casting, brass die casting, copper die casting and etc.

Advantage of Die Casting

High Material Utilization Rate

Due to the high precision of casting process, die-casting parts can be assembled and used only after a small amount of mechanical processing, and some die-casting parts can be directly assembled and used. The material utilization rate is about 60%-80%, and the blank utilization rate reaches 90%.

Good Product Quality

The dimensional accuracy of hot chamber die casting and cold chamber die castingengineering is high, generally equivalent to 6~7, or even up to 4; the surface finish is good, generally equivalent to 5~8; the strength and hardness are higher, and the strength is generally 25~30% higher than sand casting, but it is extended.The rate is reduced by about 70%; the size is stable, and the interchangeability is good; it can be used in thin-walled complex castings. For example, the current minimum wall thickness of zinc alloy die castings can reach 0.3 mm; aluminum alloy castings can reach 0.5 mm; the minimum casting aperture is 0.7 mm, and the minimum pitch is 0.75 mm.

High Production Efficiency

Machine productivity is high. For example, the domestic JⅢ3 horizontal cold-air die casting machine can die-cast 600-700 times in eight hours on average, and the small hot-chamber die-casting machine can die-cast 3,000-7000 times in eight hours on average. The die-casting mold has a long life and one pair of die-casting molds. The die-cast clock alloy has a life span of hundreds of thousands or even millions of times; it is easy to realize mechanization and automation.

Excellent Economic Effect

Due to the precise size of the die-casting, the surface is smooth and clean. Generally, it is not used for mechanical processing but directly used, or the processing volume is small, so it not only improves the utilization rate of metal but also reduces a large number of processing equipment and man-hours; and reduces die casting cost; combination die-casting can be used with other metal or non-metal materials. Our mental casting services like iron casting services save not only assembly man-hours but also metal.

Easy To Use Inserts

It is easy to set a positioning mechanism on the die-casting mold to facilitate insert casting of inserts and meet the local special performance requirements of die-casting parts.

If you have needs to experience high quality cnc machining services china, please leave us a message.

Send product request

Other supplier products

| Construction Automotive With CNC Machining | As a professional automotive metal stamping companiesand automotive plastic injection molding companies, ETCN supplying range can cover architectur... | |

| CNC Grinding | After CNC milling or CNC turning forming, the surface roughness and behavior tolerance requirements of products are completed by cnc grinding, and ... | |

| Construction Automotive With CNC Machining | As a professional automotive metal stampingand automotive plastic injection moldingcompany, ETCN supplying range can cover architectural sheet meta... | |

| CNC Milling | CNC Milling CNC milling processing is suitable for precision and complex parts processing, periodically repeated production parts processing, mult... | |

| Extrusion Molding | The products are processed by extrusion molding, with a smooth surface and high dimensional accuracy. Products of different sizes, colors, and type... |

Same products

| 39/52/65kW 61.44kWh Small-Scale C&L Energy Storage System | Seller: Shenzhen Changing Technology Co., Ltd | 39/52/65kW 61.44kWh Small-Scale C&L Energy Storage System ICHES-B is a high-voltage energy s... | |

| 24V 60Ah Lithium-ion Battery for Golf Cart | Seller: Shenzhen Changing Technology Co., Ltd | 24V 60Ah Lithium-ion Battery for Golf Cart The UT-GC2 Series 24V 60Ah Golf Cart Lithium-ion Batt... | |

| The 332.8V 10kWh (Single Phase) | Seller: Shenzhen Changing Technology Co., Ltd | The 332.8V 10kWh (Single Phase) Residential Energy Storage Systemis a high-capacity, premium-grad... | |

| 220/230/240V 5kWh - Residential Energy Storage System | Seller: Shenzhen Changing Technology Co., Ltd | 220/230/240V 5kWh - Residential Energy Storage System The 220/230/240V 5kWh Residential Energy S... | |

| Stationary Valve Core Grinding Bench | Seller: Metals Kingdom Industry Limited | Stationary Valve Core Grinding Bench is suitable for the valve disks of gate valves and ... |