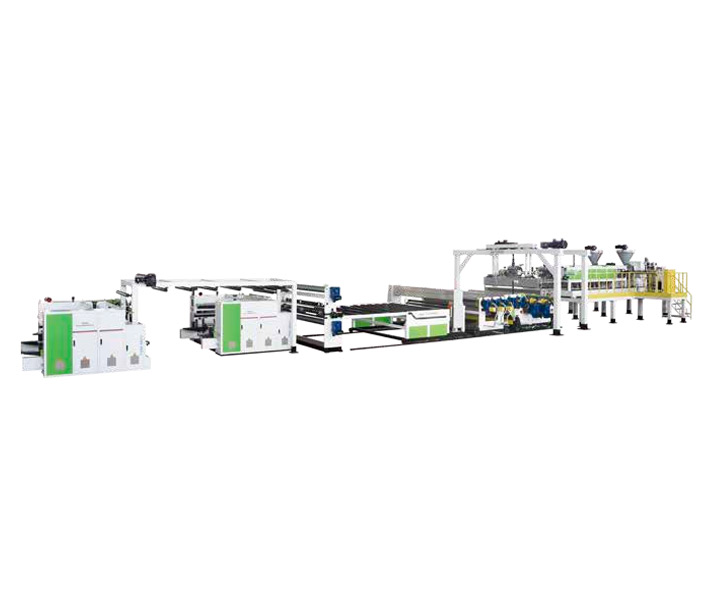

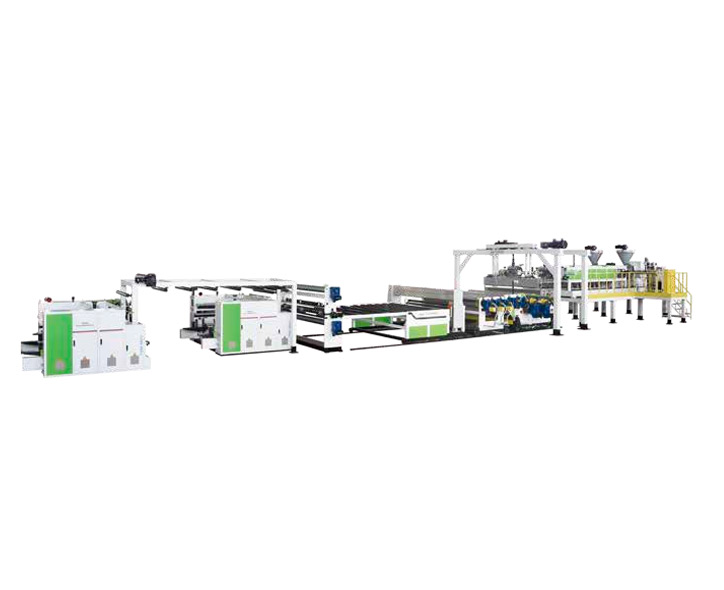

PVC Foam Board Extrusion Line

We have researched and developed on PVC skinning foam board extrusion machine for over 25 years, and have exported thousands of full PVC foam board production line to many countries with rich experience. Our PVC foam extrusion line adopts professional extrusion technology of free foam board and skinning foam board, so that PVC foam boards produced by our machine have the features of uniform foaming, smooth surface, low density, high strength and waterproof.

Our PVC skinning foam board extrusion linehas the advantages of high automation, stable production, easy operation, high efficient and sustainable after-sales service, which has received much praise from many customers all around the world. Before shipment, each extruder machine for plasticwill undergo strict testing and qualified commissioning.

PVC Foam Board Extrusion Line Advantages

Professional screw structure designed by our own company highly improves the extrusion effect and output.

To fully capitalize the power of our twin screw extruder, complete accessories and technology supporting are available to build high-performance customised lines.

Jwell extrusion machineryisa manufacturing vendor with vertical set-up, which means we have a great control of supply chain and we are cost-effective.

Precise temperature and pressure control system, speed monitoring device, which guarantee high quality of final PVC foam board and smooth PVC foam board production process.

Our plastic board extrusion line combine energy conservation and high speed production in this PVC foam extrusion machine.

PVC Foam Board Extrusion Line Specification

|

Model |

Co-extrusion foamed board extrusion line |

Skinning foaming board extrusion line |

|

Production width |

1220~1560mm |

1220~1560mm |

|

Production thickness |

5-20mm/20-35mm |

5-20mm /20-35mm |

|

Extruder model |

SJZ65/132, SJZ80/156 |

SJZ80/156 |

|

Capacity (Max.) |

400~550kg/h |

300~450Kg/h |

|

Main motor power |

37kw/75kw |

75kw |

PVC Foam Board Extrusion Line Features

Cooling Bracket of PVC Foam Board Extrusion Line

Cooling Bracket

Stainless steel roller with polished treatment.

Cooling bracket length: 5000mm.

Cooling roller size: Φ70×1500mm.

Side cutting device, two sets of knife, distance is adjustable.

Haul Off of PVC Foam Board Extrusion Line

Haul Off

Specifications of the 8 pairs rubber rollers: Φ200mmx1500mm.

Speed controlled by imported inverter and reduction motor.

Cutter of PVC Foam Board Extrusion Line

Cutter

Longitudinal and cross cutting.

14# alloy saw, fast cutting, flat section.

Dust vacuuming unit with powerful vacuum pump.

PVC Foam Board Extrusion Line Application

PVC foam boards are widely used in transportation industry, construction and decoration industry, such as boards on ship, plane, bus, train chamber, indoor decorative wall board, building board, cupboard, table board, etc.

After printing, lamination and hot stamping process, the foam boards have various designs and patterns, which are very popular in market.

Send product request

Other supplier products

| CPP, CPE Cast Film Extrusion Line | We are professional at manufacturing complete film extrusion line with over 25 years' rich experience, highly improving the production efficiency a... | |

| Blow Molding Line | Jwell provide 7 types plastic blow molding machines for different application in automobile industry, transportation, chemical packaging, household... | |

| Plate & Sheet Extrusion Line | The full range of plastic sheet and plastic plate extrusion lineadopt professional single or twin screws designed and produced by our own sheet ext... | |

| Film Extrusion Line | We have own experimental institution and professional company to research and develop high-performance plastic film extrusion machines. The main fi... | |

| Film Extrusion Line | We have own experimental institution and professional company to research and develop high-performance plastic film extrusion machines. The main fi... |

Same products

| Mobile Trailer-mounted Emergency Rescue Double Suction Split Case Diesel Water Pumps | Seller: Guangxi Dingbo Power Equipment Manufacturing Co.,Ltd | Mobile Trailer-mounted Emergency Rescue Double Suction Split Case Diesel Water Pumps This is a m... | |

| Reform the Manual Production Line to Automatic | Seller: Chengdu Duolin Electric Co.,Ltd | Reform the Manual Production Line to Automatic Under background of industry 4.0 and customer new... | |

| China Manufacture Robot Arm Gearbox RV Gearbox | Seller: Zhejiang Qiyue Mechanical Technology Co.,Ltd. | China Manufacture Robot Arm Gearbox RV Gearbox Which is also known asRV gearsor cycloidal reduce... | |

| Planetary Gearbox | Seller: Zhejiang Qiyue Mechanical Technology Co.,Ltd. | Planetary Gearbox The planetary gearbox is designed in overall square. Three integrated designs,... | |

| High Quality Zero Backlash Harmonic Drive ADH-V | Seller: Zhejiang Qiyue Mechanical Technology Co.,Ltd. | High Quality Zero Backlash Harmonic Drive ADH-V Which is a compact structure mechanism including... |