Car Light Mould

The car light mould plays a vital role in illuminating vehicles, serving as the eyes of cars. It encompasses all the lighting systems employed in automobiles. The design and production of auto lamp mould necessitate meticulous attention due to the exacting requirements of automobile light appearance. Transparent and electroplated components constitute several critical parts of these lights. The lamp itself stands out as the most demanding element in the car's aesthetic. The front and rear headlights represent the primary illumination sources for most cars. Lighting configurations differ across various car series, while even within the same series, variations exist based on height configuration. The key components comprising the front and rear lights of a car include left and right lenses, decorative frames, lamp housings, reflectors, among others.

Car Light Mould Appearance Requirements

Lens (Material: Transparent PC): Steel CAV / COR: NAK80 or S136H (HRC33-37), the hardness of the cavity and core is staggered. The product is highly polished, can't pass the whetstone, save the mold to 1000# sandpaper and then polish.

The decorative frame ( Material PBT ): Mold Steel: CAV: NAK80 or S136H (HRC33-37), COR: forged steel HRC31-35, the product is highly polished, can not pass whetstone save the mold to 1000# sandpaper and then polish. The cavity side ( reflective surface) can not be welded.

Reflector (Material BMC): The cavity and core are made of 8407 steel (to achieve a high polishing effect), the cavity steel is HRC46-50, and the core steel is HRC44-48. The cavity side (reflecting surface) is high polished, and can not pass the whetstone, save the mold to 1000# sandpaper and then polish, the core side is generally 600# polished.

Car Light Mould Technology Summary

Plastic features: transparent color, high requirements for the appearance surface, no spots/gate/marks, no bubbles/ fog halo/shrinkage mark/ welding lines, and other forming defects.

In view of the plastic color transparent, the use of an ordinary runner can avoid the plastic color difference, improve transparency, coupled with the plastic surface is not allowed to have gate marks, so use the side gate gating system.

Car light mould adopts the combined cooling system of "vertical cooling water pipe, inclined cooling lines, and splice water well", and the waterway is arranged along the cavity, effectively ensuring the precision of the plastic parts and the labor productivity of the mold. The plastic parts are ejected out by an ejector block, which is not only stable but also leaves no influence on the appearance of the product.

In the molding of transparent mold, the design of the exhaust system is very important, such as poor exhaust, will seriously affect the quality of plastic parts, in view of the product material for PC, exhaust front-end design for 0.02mm, around the product according to CAE analysis of reasonable design exhaust, reduce the bubble or air trapping caused by local burns and other problems during injection molding.

For more information about plastics molders, please feel free to contact us!

Other supplier products

|

|

Plastic Food Container Mould |

Plastic meal boxes mainly used for packing foods, so it need to be heat resistant and non-toxic,and could meet the requirements of environmental pr... |

|

|

Electronics Mold |

Consumer electronics is very popular in our daily life. It consists of many different plastic parts, pcb boards, wires, battery and some metal part... |

|

|

Industrial Plastic Injection Mold |

The injection molding part is replacing metal products in many fields of industrial applications to meet the requirement of lightweight industrial ... |

|

|

LCD TV Mould |

TV screen frame mold is used to produce TV screen frames, it should be strong and assembly well with the screen. It has an undercut to lock the scr... |

|

|

Plastic Toilet Seat Mold |

Toilet seat mouldquality points: cover mold cycle, cover mold life, Parting line whether there are sharp edges? Is the cover wall thickness even? H... |

All supplier products

Same products

|

|

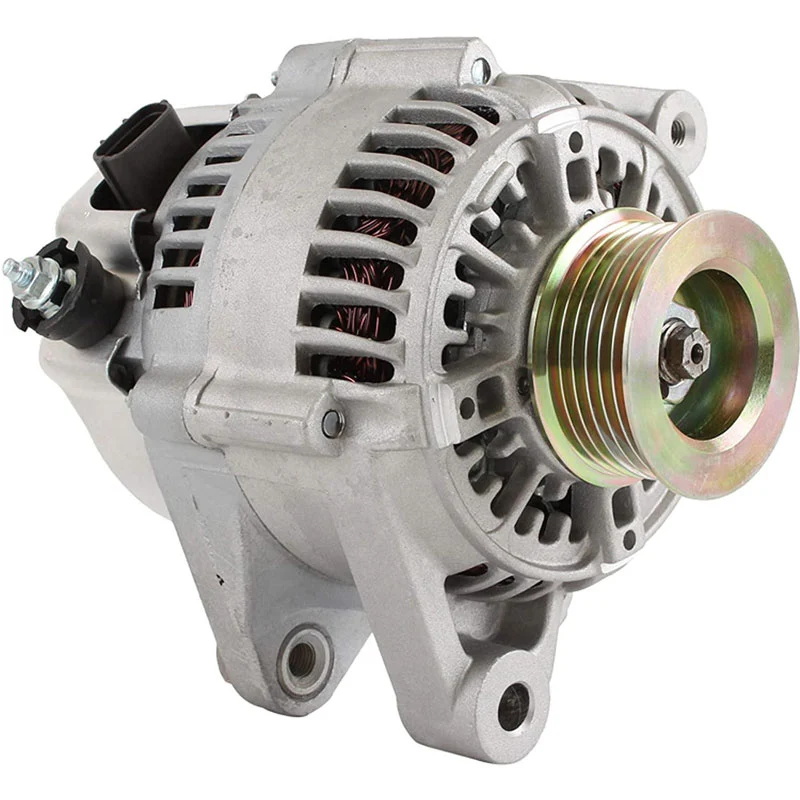

OEM Car Parts Alternator for Toyota |

Seller: Foshan Bohua Auto Parts Co., Ltd |

Automobile alternator, which is the main power supply of the automobile, is driven by the engine.... |

|

|

OEM Parts of Alternator in Car for Toyota |

Seller: Foshan Bohua Auto Parts Co., Ltd |

OEM Parts of Alternator in Carfor Toyota

Automobile alternator, which is the main power supply ... |

|

|

OEM Alternator Wholesale for Toyota |

Seller: Foshan Bohua Auto Parts Co., Ltd |

Automobile alternator wholesale, which is the main power supply of the automobile, is driven by t... |

|

|

OEM Automotive Alternator Parts for Toyota |

Seller: Foshan Bohua Auto Parts Co., Ltd |

The OEM part number refers to automotive alternator partsspecifically designed for Toyota vehicl... |

|

|

OEM Auto Parts Alternator for Toyota |

Seller: Foshan Bohua Auto Parts Co., Ltd |

Auto parts alternator, which is the main power supply of the automobile, is driven by the engine.... |