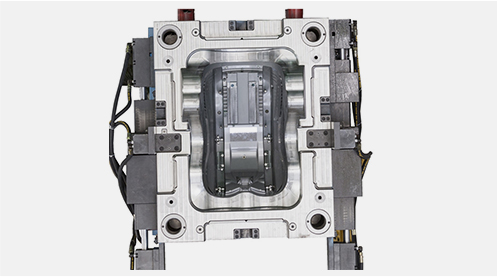

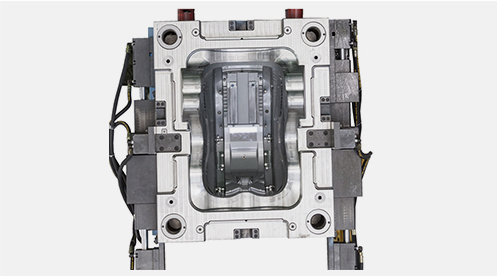

Mouse Mold

One computer mouse usually includes these plastic parts: a bottom shell, an upper cover, a middle cover, a wheel, a base of wheel, a frame which connects with electronic elements etc. These plastic parts are required not only to be textured well, but also to be wear-resistant. In addition, because it is an electronic housing, it needs to be assembled with electronic components, so the precision requirements for plastic products are relatively high. Green Vitality provide high quality mouse molds within a very short time. Our customers are satisfied with our professionalism and service.

Advantages of Project Management for Molding Electronic Products

Green Vitality Industry is a professional plastic mold and molding manufacturer which has 25years of experience in the plastic mold industry. We have below advantages which our customers benefit from us and we grow up as well thanks to our customers' trust and support.

Electronic Injection Molding Experts

Flexible OEM service is available, Steady Engineering team provides advice and solution to part moldability and error prevention for the overall project purpose.

Commitment to Quality

We believe in and practice the "Quality is of Prime Importance" philosophy. Well-versed manufacturing team to manage the mold machining and injection processing. QA department performs strong quality assurance in order that all products and services meet or exceed the expecting needs.

Competitive Price

With diversity in equipment capabilities and in-depth knowledge about industrial injection mold, Green Vitality is able to offer Competitive Prices for all products and services reasonably.

In-time Delivery

The professional team creates and executes the most efficient schedule for the respective project task, and helps arrange delivery at the economical possible cost.

Process of Injection mouse mould / mice moulds

Before making a production mold, we usually verify the plastic product & mold in the following steps. In this way, we can speed up product development, effectively control mold costs, reduce mold repair costs in the manufacturing stage, and fully verify product performance as much as possible to save time and cost.

The first stage: prototype sample

The prototype part is not only visible, but also can be assembled, it can intuitively reflect whether the structure is reasonable or not, and the difficulty of installation. It is convenient to detect and solve problems in the early stage. Usually made by rapid prototyping parts, CNC processed rapid prototypes, and 3D printing within 1 week.

The second stage: soft tooling

After the prototype parts verification, we will improve the problems found, and then carry out a small batch assembly test. In addition, in order to carry out more sufficient verification and avoid the risk of mold scrap, usually at this stage, we will first develop a lower cost soft mold to verify the mold structure and mold feasibility, and the material and structure of the parts are the same to mass-produced parts. Soft molds can typically produce no more than 10,000 shots.

The third stage: production tooling

After the parts have been fully verified and approved, the official steel mold is developed. The official steel mold can produce 200000, 500000, or 1000000 parts according to different steel materials used, and select the appropriate steel material according to the planned output

For more information about injection parts, please feel free to contact us!

Other supplier products

|

|

Car Seat Mould for Kids |

Car Seat Mouldfor Kids

Child mouldy car seatsspecially designed to protect children from injury or death in a collision. The main structure of the... |

|

|

Home Appliance Mould |

Home Appliance Mould

GV Mold has rich experience in home appliance mold(such as television, refrigerators, fans, washing machines, air conditi... |

|

|

Plastic Food Container Mould |

Plastic meal boxes mainly used for packing foods, so it need to be heat resistant and non-toxic,and could meet the requirements of environmental pr... |

|

|

Teeth Tray Mold |

A dental impression is a mold removed from a tooth to diagnose and treat dental conditions. They are also used in forensic science. Impressions are... |

|

|

Car Seat Mould for Kids |

Child safety seats are seats specially designed to protect children from injury or death in a collision. The main structure of the child safety sea... |

All supplier products

Same products

|

|

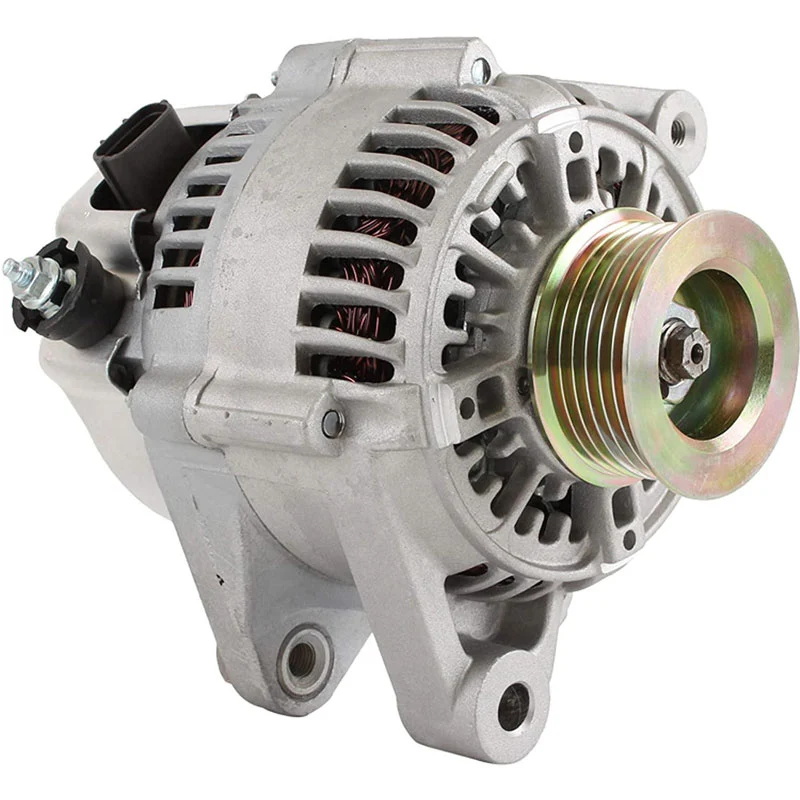

OEM Car Parts Alternator for Toyota |

Seller: Foshan Bohua Auto Parts Co., Ltd |

Automobile alternator, which is the main power supply of the automobile, is driven by the engine.... |

|

|

OEM Parts of Alternator in Car for Toyota |

Seller: Foshan Bohua Auto Parts Co., Ltd |

OEM Parts of Alternator in Carfor Toyota

Automobile alternator, which is the main power supply ... |

|

|

OEM Alternator Wholesale for Toyota |

Seller: Foshan Bohua Auto Parts Co., Ltd |

Automobile alternator wholesale, which is the main power supply of the automobile, is driven by t... |

|

|

OEM Automotive Alternator Parts for Toyota |

Seller: Foshan Bohua Auto Parts Co., Ltd |

The OEM part number refers to automotive alternator partsspecifically designed for Toyota vehicl... |

|

|

OEM Auto Parts Alternator for Toyota |

Seller: Foshan Bohua Auto Parts Co., Ltd |

Auto parts alternator, which is the main power supply of the automobile, is driven by the engine.... |