Production Improvement of the Coal Briquette Machine

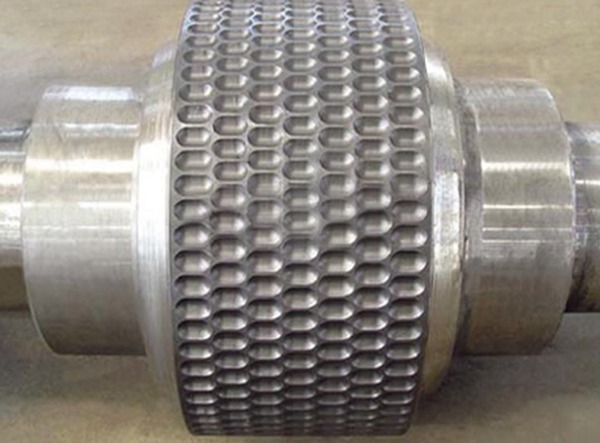

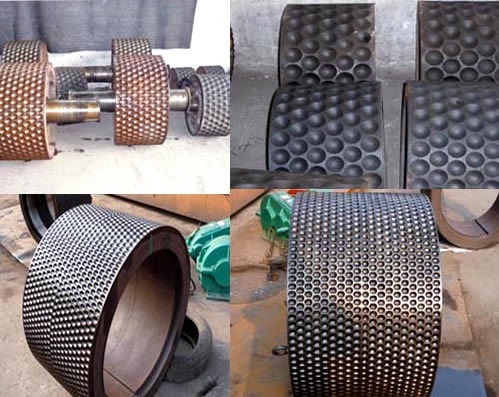

As is known by us, the coal briquette machine is mainly used to compress all kinds of powder materials (like cola powder) into briquettes or pellets. According to Fote professionals, the coal briquetting machines are experiencing constant improvement for both products and technologies.

Today let’s talk about the production improvement of the coal briquette machine and briquetting industry. There are mainly six respects as follows:

1.In the real production, we recommend users to adopt mill coals including smokeless powdered coal, meager coal and half coke powder as raw material sources in order to reduce the coal briquetting cost.

2.The on-site formation of the coal briquette machine is more helpful to reduce the production cost and proposes few requirements for the equipment properties like the water resistance. Especially for those processes adopting the inorganic binders, it’s better to realize on-site formation because the useless ash content transportation expense is saved.

3.Speaking of the ash content, we should keep up with the international production technology. In order to reduce the ash content of the coal briquettes, we can wash and separate the raw coal first to improve the fixed carbon content.

4.It’s important to perfect the coal briquetting process by doing research and development on the coal briquette machine and its auxiliary devices like the rotary dryer.

5.As an ideal raw material, the formed coke can improve the final quality and expand the application range of the final coal briquettes. To extend the coke material source will be the future development tendency for the coal briquetting machines.

The coal briquette machine is a green product made by Fote Heavy Machinery (), a leading mining machinery manufacturer, so the production improvement is helpful for us to realize the environment protection and energy saving goals.

Send product request

Other supplier products

| Hydraulic Pressure Briquette Machine Creates Economic Benefit | Fote hydraulic pressure briquette machine has been used in many industries, and it is popular in many countries, like America, Britain, France, Ger... | |

| The Gypsum Briquetting Machine with High Quality and Competitive Price | The right selection of desulfurization gypsum briquette machine can reduce your investment risk. In order to increase profits and reduce the invest... | |

| Tree Bark Pellet Mill with High Production and Quality | Fote Machinery tree bark pellet mill is mainly used to crush bark, sawdust and wood chips etc. into granulation. In order to build an environment-f... | |

| ring die wood pellet machine/Wood Pellet Mill/New Type Wood Pellet Machine | ring die wood pellet machine, Wood Pellet Mill, New Type Wood Pellet Machine Some Questions about Wood Pellet Mill 1. What is the type of your pell... | |

| Sawdust Pellet Mill/High Quality Sawdust Pellet Mill/Small Sawdust Pellet Mill | Sawdust Pellet Mill, High Quality Sawdust Pellet Mill, Small Sawdust Pellet Mill Requirements for Making Wood Pellet a. size of raw materials: powd... |

Same products

| XD-MAX Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | Seller: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Seller: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Seller: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |