Ceramic Membrane

Ceramic membranes are available for microfiltration, ultrafiltration and nanofiltration as single-channel or multiple-channel elements with channel diameters between 2 and 16mm.

Their main characteristics of

- Consistent pore size;

- Very narrow mean pore-size distribution;

- Long and reliable lifetime;

- High permeate flux;

- Greater void area per unit area of filtration surface;

- High stability to organic media;

- High-pressure resistance, high-temperature resistance;

- Rigid with no creep or deformation;

- Stable over a wide pH range;

- Membranes bonded to substrate by strong ceramic bonds;

- Corrosion & abrasion resistant;

- Insensitive to bacterial action;

- Can be repeatedly sterilized by steam or chemicals;

- Ability to backwashed;

- The possibility of regeneration after fouling;

- Can process highly viscous fluids;

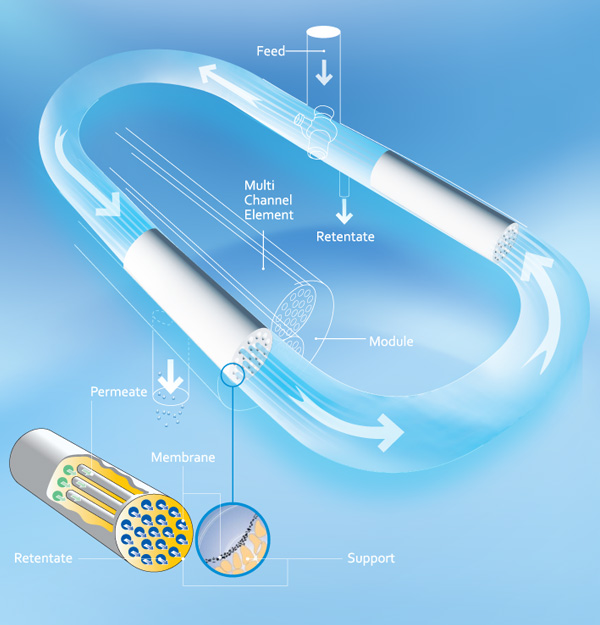

The principle of ceramic membrane The principle of the filtration is based on two opposing effects: on the one hand, the particles are transported by the filtration flux to the where they cause an increase in concentration; on the other hand, concentration differences are again reduced by the turbulence of the cross-flow and by Brownian motion of the particles.

During filtration by means of ceramic membranes made by JIUWU the medium to be filtered flows through the channels of the membrane support. All particles whose size exceeds the pore radius of the membrane are retained. The particles /molecules build up in the concentrate. The filtrate permeates through the pores and depending on the procedure is subjected to subsequent process stages. This filtering method is also called “cross-flow filtration” or “dynamic filtration”. Cross-flow management can achieve stable fluxes. Still, the cleaning of cross-flow installations needs to be applied from time to time. Cleaning is performed by means of backward flushing or chemical cleaning.

Send product request

Other supplier products

| Ceramic Membrane | Ceramic membranes are available for microfiltration, ultrafiltration and nanofiltration as single-channel or multiple-channel elements with channel... | |

| Ceramic Membrane Module | Ceramic Membrane Products A ceramic membrane moduleis a complete unit composed of the ceramic membranes, housing, feed inlet, concentrate outlet, ... | |

| Fruit And Vegetable Juice | Fruit And Vegetable Juice APPLE JUICE Apple juice in the press process will bring a lot of impurities in pulp, pectin, starch, plant fiber, micro... | |

| Non-Alcohol Beer And No Alcohol Wine | Ceramic membraneand other hi-tech membrane technology serve an important role in our daily life. JIUWUworks to provide our customers with the best ... | |

| Microfiltration Ceramic Membrane Element | The ceramic microfiltration membraneelement ( MF membrane) is made from alumina and zirconia which is an asymmetric membrane structure with multi-c... |

Same products

| Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant Why Choose anInclined Belt Planetar... | |

| Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift | Seller: Yousheng Machinery Equipment Co.,Ltd | Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift Vertical Shaft Planetar... | |

| High-Discharge Mobile Concrete Batching Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | High-Discharge Mobile Concrete Batching Plant High-Discharge Mobile Concrete Batching Plantinteg... | |

| Forced Mobile Concrete Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | Forced Mobile Concrete Plant Introducing our versatile forced concrete mixer: compact for tight ... | |

| Waste Aluminum Plastic Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... |