Fufu Machine

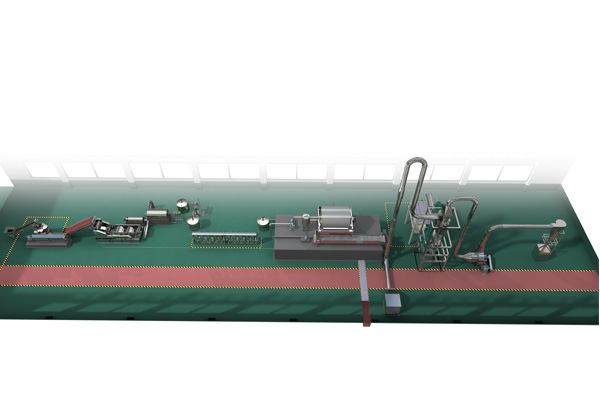

Fufu Process Description and Flowchart:

Fufu (variants of the name include foofoo, fufuo, foufou) is a staple food with deep roots in Ghana's history and common in many countries of West Africa and the Caribbean. It is often made with cassava flour. Other flours, such as semolina, maize flour or mashed plantains may take the place of cassava flour. Fufu served alongside soup, usually, groundnut soup is a national dish of Ghana.

Goodway focuses on providing solutions of fufu making machine and cassava fufu processing production line since 1991.

Multiple distinct operations are required in fufu processing: washing, peeling, chipping, fermenting, grating, pressing, breaking & sifting, fufu drying, milling, and packaging.

We provide below a brief description of the main steps of the fufu production process.

Cleaning and Washing Cassava Roots

Wash the fresh cassava roots in clean water to remove the surface mud and sand. It's the first step of the fufu process and very important for the quality of final

Fufu machine(foofoo).

Peeling Cassava Roots

Peeling Cassava Roots

Peel the washed cassava roots to remove the outer brown skin and inner thick cream layer. The water source should be checked regularly to ensure it is not dirty or contaminated.

Cutting Cassava Roots into Cassava Chips

Cutting Cassava Roots into Cassava Chips

Cut the peeled cassava roots into chips by the high speed rotating circular cutter blade, then cut the chips into strips by the cross cutter blade.

Fermenting Cassava Chips or Strips on the Fermentation Rack:

Fermenting Cassava Chips or Strips on the Fermentation Rack:

Collect the cassava chips or strips into a clean polythene sack and tie, then bagged cassava chips or strips can be left in the fermentation rack for one or more days before grating, allow the milky water to drain freely from the bags.

Grating Fermented Cassava Chips into Mash

Grating Fermented Cassava Chips into Mash

Load the grater with fermented cassava chips while the engine is running to grate peeled cassava chips into the mash. The grating drum and all food contact areas should be made from stainless steel.

De-watering Mash into Wet Cake

De-watering Mash into Wet Cake

Load the bags directly on to a hydraulic press. Lift and press the jack handle up and down until it becomes hard to move. Repeat the process several times each day until no more water comes out of the bag to produce a firm wet cake.

Breaking Wet Cake and Sifting Wet Cake into Grits

Breaking Wet Cake and Sifting Wet Cake into Grits

Breaking the wet cake into small pieces (grits) and remove the lumps to obtain uniform size grits(wet coarse fufu). All food contact areas should be made from stainless steel

Drying Grits into Dried Coarse Fufu

Drying Grits into Dried Coarse Fufu

Dry the grits(wet coarse fufu) into dried coarse fufu with low moisture content by the principle of heat transfer exchange.

Milling Coarse fufu into Fine fufu

Milling Coarse fufu into Fine fufu

Milling the dried coarse fufu into fine fufu with the uniform size, then pour the fufu into a plastic lining inside a woven polythene sack.

Send product request

Other supplier products

| Cassava Processing Machine | As one of cassava processing machines manufacturersand cassava processing machinery suppliers, Goodway can provide the complete set of from cassava... | |

| Potato Washing Machine | cassava flour milling machinecassava machinecassava processing machine Features of Potato Washing Equipment Processing Capacity: 3-20Tons/hourAppl... | |

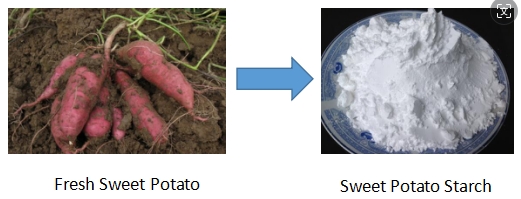

| Sweet Potato Starch Machine | Features of Sweet Potato Starch Machine Sweet Potato Starch Process Description and Flowchart: Goodway has been continuously developing sweet pot... | |

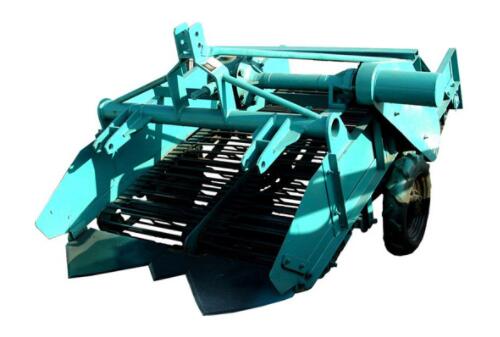

| Cassava Harvesting Machine | Features of Cassava Harvesting Machine Processing Capacity: 3-5 Acre/hour Application Scope: Harvesting the fresh cassava roots automatically Prod... | |

| Garri Processing Machinery | Cassava Garri(Gari) Process Description and Flowchart: Garri is a fermented and gelatinized dry coarse flour, very popular in West Africa and a sta... |

Same products

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Seller: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Seller: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... | |

| 3 in1 Decoiler Leveler Feeder | Seller: Dongguan YouYi Precision Automation Equipment Co., Ltd. | 3 in1 Decoiler Leveler Feeder For Thin Plate(0.3-3.2mm) The 3-in-1 servo feederintegrates four f... | |

| NC Servo Feeder (0.1-3.0mm) | Seller: Dongguan YouYi Precision Automation Equipment Co., Ltd. | NC Servo Feeder (0.1-3.0mm) Our standard servo feederis engineered for precision coil feeding of... | |

| Uratech 40 Taper CNC Tower – CAT 40 Tool Cart & CNC Tool Holder Storage | Seller: Uratech USA Inc | TheUratech 40 Taper CNC Toweris the ultimate solution for organizing and protecting your CNC tool... |