Cassava Chips Cutting Machine

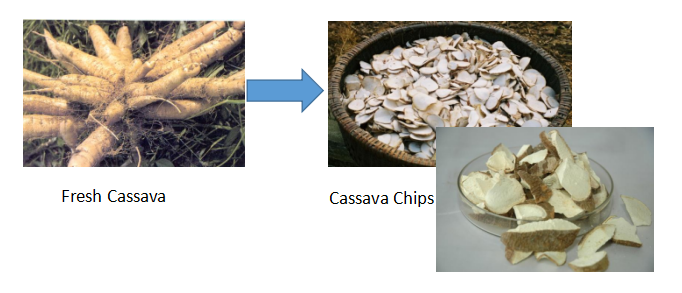

Cassava Chips Process Description and Flowchart:

Cassava chips are one kind of chips or slices made from fresh cassava roots, as snacks or animal feed popular in many countries of West Africa and the Caribbean.Goodway has 27 years of combined experience in the cassava slicer machineand cassava chips processing production line.

Multiple distinct operations are required in cassava chips processing: washing, peeling, slicing, chips drying and packaging.

We provide below a brief description of the main steps of the cassava chips productionprocess.

Cleaning and Washing Cassava Roots

Wash the fresh cassava roots in clean water to remove the surface mud and sand. It's the first step of cassava chips process and very important for the quality of final cassava slicer.

Peeling Cassava Roots

Peeling Cassava Roots

Peel the washed cassava roots to remove the outer brown skin and inner thick cream layer. The water source should be checked regularly to ensure it is not dirty or contaminated.

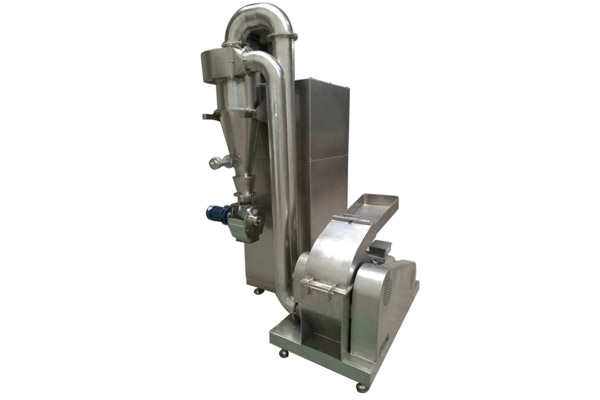

Cutting Cassava Roots into Wet Cassava Chips

Cutting Cassava Roots into Wet Cassava Chips

Cut the peeled cassava roots into chips by the high speed rotating circular cutter blade, then cut the chips into strips by the cross cutter blade.

Drying Wet Cassava Chips into Dried Cassava Chips

Drying Wet Cassava Chips into Dried Cassava Chips

Dry the wet cassava chips into dried cassava chips with low moisture content by the principle of heat transfer exchange.

Send product request

Other supplier products

| Cassava Peeling Machine 2019 | Features of Cassava Peeling Machine Processing Capacity: 4-6Tons/hour Application Scope: Fresh cassava peeling and washing Product Introduction: C... | |

| Cassava Flour Milling Machine | Features of Cassava Flour Milling Machine Processing Capacity: 400-500kgs/hour Application Scope: Milling the coarse powder into fine powder Produ... | |

| Cassava Flour Machine | Cassava Flour Production Process Description and Flowchart: Cassava flour is also called cassava whole flour, which is the fine powder, a little ye... | |

| Garri Processing Machinery | Features of gari making machine Cassava Garri(Gari) Process Description and Flowchart: Garri is a fermented and gelatinized dry coarse flour, ver... | |

| Hydraulic Dewatering Press | Hydraulic Dewatering Press sava processing machine Features of Hydraulic Dewatering Press Processing Capacity: 100-500kgs/hourApplication Scope: C... |

Same products

| Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant Why Choose anInclined Belt Planetar... | |

| Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift | Seller: Yousheng Machinery Equipment Co.,Ltd | Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift Vertical Shaft Planetar... | |

| High-Discharge Mobile Concrete Batching Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | High-Discharge Mobile Concrete Batching Plant High-Discharge Mobile Concrete Batching Plantinteg... | |

| Forced Mobile Concrete Plant | Seller: Yousheng Machinery Equipment Co.,Ltd | Forced Mobile Concrete Plant Introducing our versatile forced concrete mixer: compact for tight ... | |

| Waste Aluminum Plastic Pyrolysis Plant | Seller: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... |